Touch control panel, preparing method of touch control panel and display device

A touch panel and touch electrode technology, which is applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of abnormal OLED light emission, cathode influence, OLED display panel cannot display normally, etc., and achieves low cost and easy implementation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

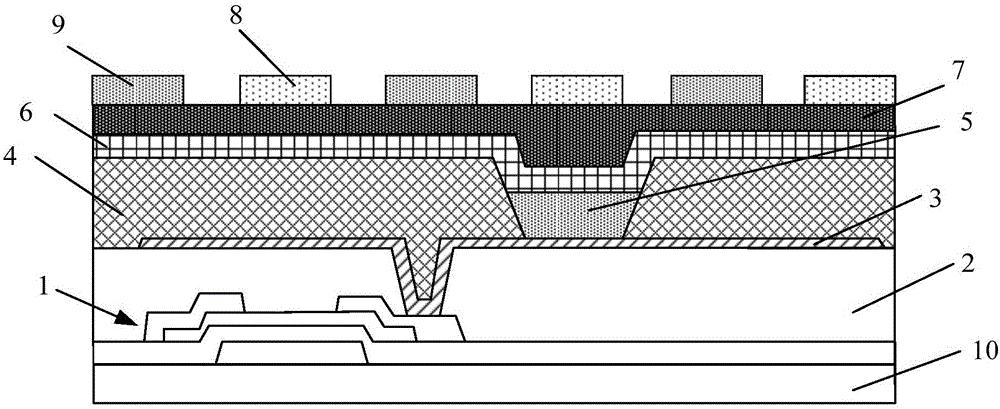

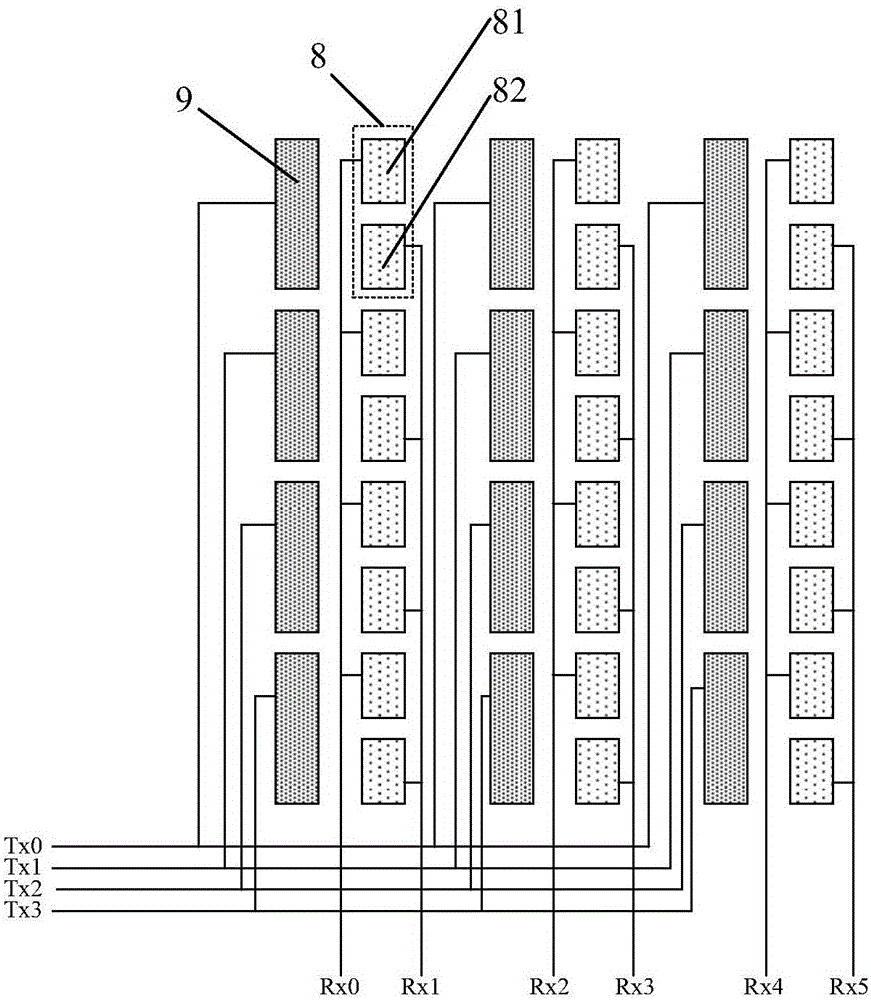

[0037] Such as Figures 1 to 3 As shown, this embodiment provides a touch panel, which includes an OLED substrate facing each other and a substrate facing each other; the OLED substrate includes at least a substrate 10, and a plurality of organic electroluminescent devices arranged above the substrate 10; The organic electroluminescent device includes a first electrode 3, a light-emitting layer 5, and a second electrode 6 sequentially arranged above the substrate 10, and the touch panel also includes an electrode arranged on the light-emitting surface side of the second electrode 6, and The second electrode 6 is a touch electrode and a sensing electrode arranged in isolation.

[0038] Since the touch electrodes and sensing electrodes of the touch panel of this embodiment are arranged on the second electrode 6 of the organic electroluminescence device, and are insulated from the second electrode 6, that is to say, the touch electrodes and the The sensing electrodes are layered...

Embodiment 2

[0051] Such as Figure 4 As shown, this embodiment provides a method for preparing a touch panel, and the method is used to prepare the touch panel described in Embodiment 1. Wherein, the first electrode 3 is an anode, and the second electrode 6 is a cathode as an example to describe the preparation method of this embodiment. The preparation method specifically includes:

[0052] Step 1, forming various layer structures including the thin film transistor 1 on the substrate 10, then forming the passivation layer 2, and etching the passivation layer 2 to form a pass for connecting the drain of the thin film transistor 1 to the anode of the organic electroluminescent device hole.

[0053] Step 2. On the substrate 10 that has completed the above steps, a pattern including the anode of the electroluminescent device is formed through a patterning process; then a pixel defining layer 4 is formed, and a luminescent material is formed in the pixel defining layer 4 to form an electrol...

Embodiment 3

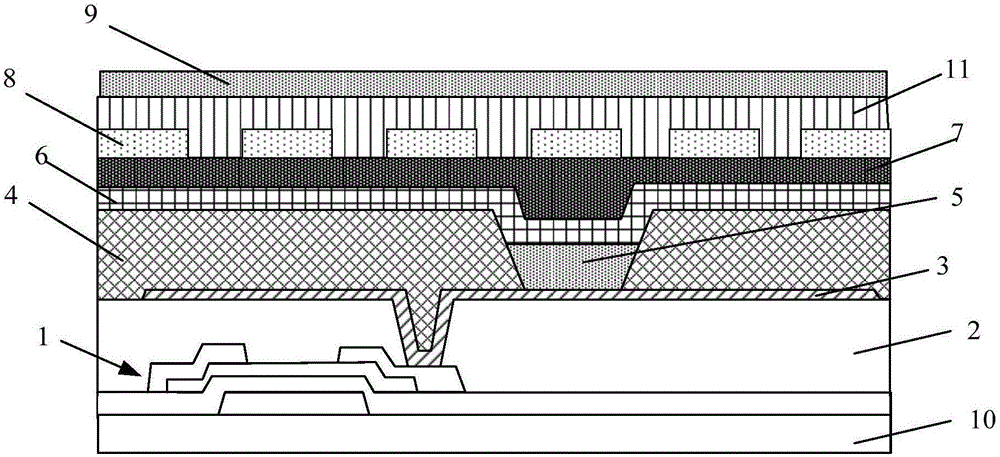

[0060] Such as Figure 5 As shown, this embodiment provides a method for preparing a touch panel, and the method is used to prepare the touch panel described in Embodiment 1. Wherein, the first electrode 3 is an anode, and the second electrode 6 is a cathode as an example to describe the preparation method of this embodiment. The preparation method specifically includes:

[0061] Step 1, forming various layer structures including the thin film transistor 1 on the substrate 10, then forming the passivation layer 2, and etching the passivation layer 2 to form a pass for connecting the drain of the thin film transistor 1 to the anode of the organic electroluminescent device hole.

[0062] Step 2. On the substrate 10 that has completed the above steps, a pattern including the anode of the electroluminescent device is formed through a patterning process; then a pixel defining layer 4 is formed, and a luminescent material is formed in the pixel defining layer 4 to form an electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com