Double-glass photovoltaic assembly

A double-glass photovoltaic and component technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of cost increase, cell fracturing, high cost, etc., solve technical problems, improve installation reliability, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

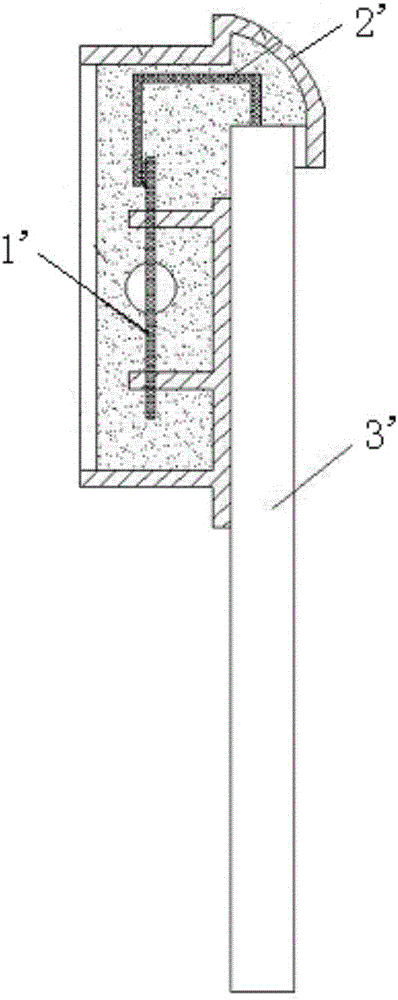

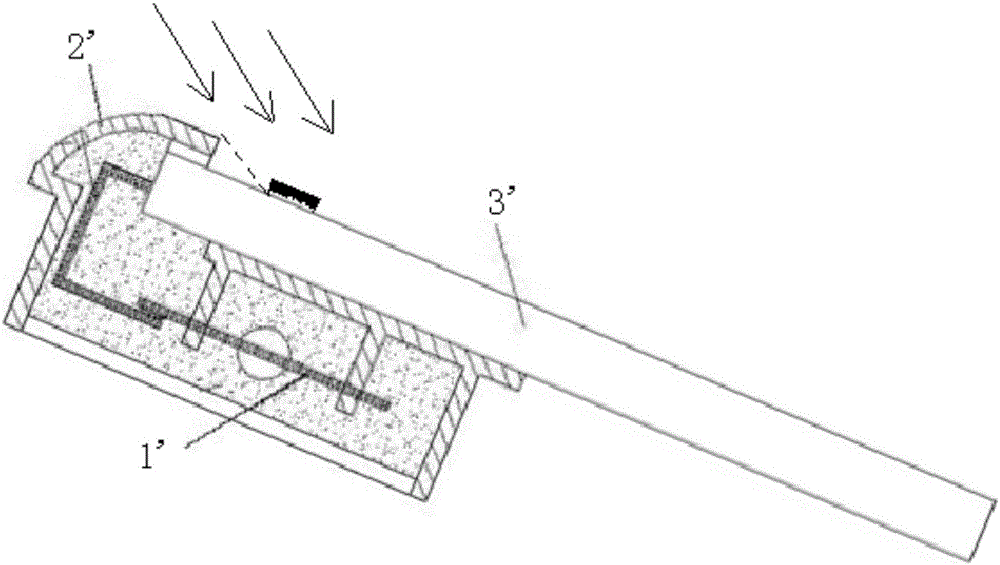

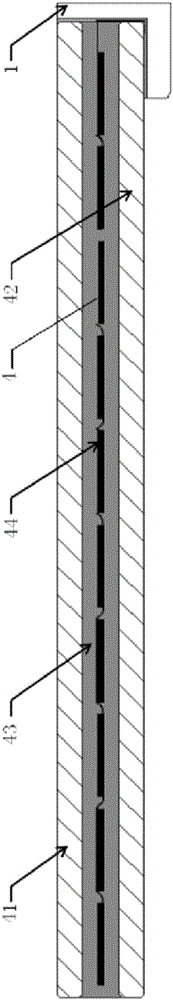

[0031] by Figure 3 to Figure 5 As shown, the specific structure of the double-glass photovoltaic module of the first embodiment is introduced:

[0032] The double-glass photovoltaic module includes a body 4 and a junction box 1 . The body 4 includes a front glass 41 and a back glass 42 , between the front glass 41 and the back glass 42 is an array of battery slices 44 encapsulated by EVA, that is, ethylene-vinyl acetate copolymer. The front and rear glass is used to replace the polymer back plate material, which saves the aluminum frame and saves production costs. The front side refers to the light-receiving side of the double-glass photovoltaic module in use, and the back side refers to the backlight side of the double-glass photovoltaic module in use. After the battery slices 44 are connected in series or in parallel, the electric energy generated by the array of battery slices 44 is transmitted to the terminal of the junction box 1 through the bus bar 45. lead out.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com