Distributed battery management system and method for lead-acid storage battery pack equalization

A battery management system, lead-acid battery technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of battery cell performance difference, positive plate active material falling off, expensive and other problems, to achieve overall cost, realization The effect of circuit reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

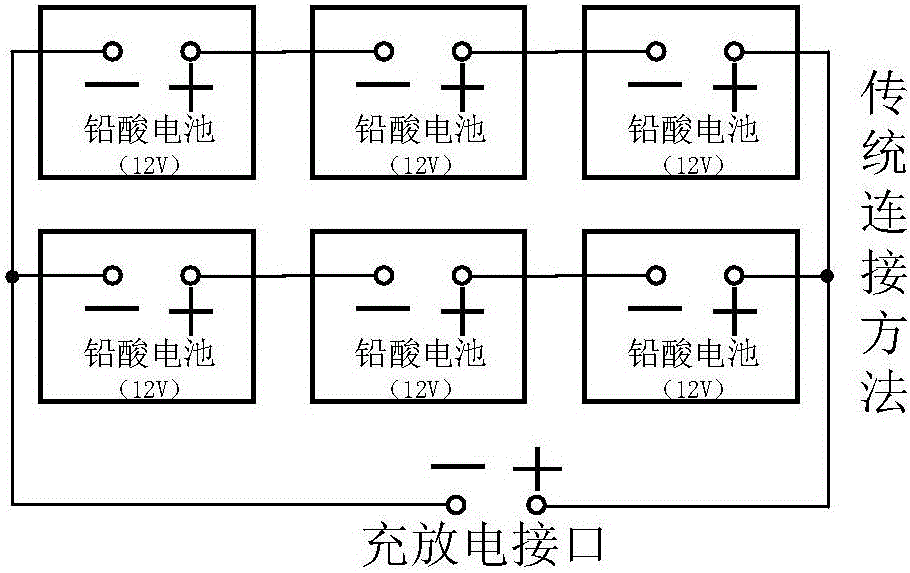

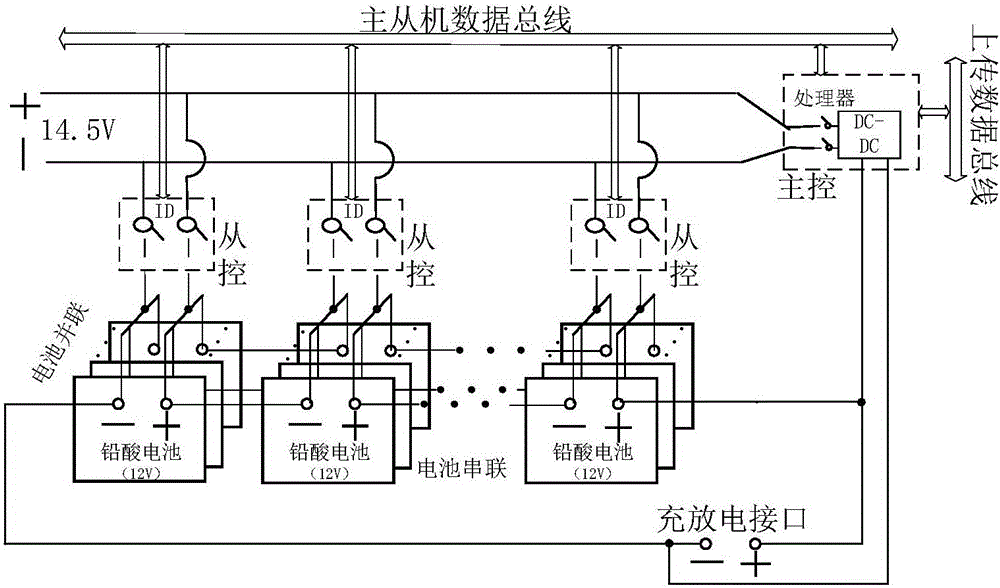

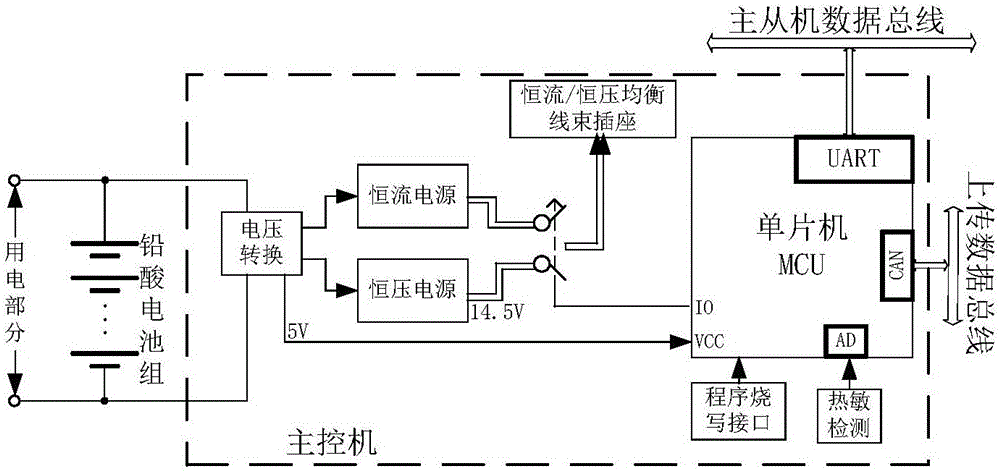

[0041] refer to figure 2, which is the structural principle diagram of the present invention, a distributed battery management system for equalizing lead-acid battery packs in the present invention, including lead-acid battery, host computer, master control unit and slave control unit, master control unit and slave control unit They are connected through the master-slave data bus communication; the master control unit leads the upload data bus to connect with the host computer, the master control unit includes a constant current / constant voltage equalization device, and the slave control unit includes an equalization switch, a plurality of Lead-acid batteries are connected in series to form a series lead-acid battery unit, and a plurality of series-connected lead-acid battery units are connected in parallel to form a lead-acid battery pack. The number is the same, each lead-acid battery is connected to a slave control unit, and the constant current / constant voltage equalizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com