High-efficiency wide-load-range three-phase micro-inverter and control method thereof

A micro-inverter, wide-load technology, applied in control/regulation systems, output power conversion devices, DC power input conversion to DC power output and other directions, can solve the problem of micro-inverter utilization limit and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

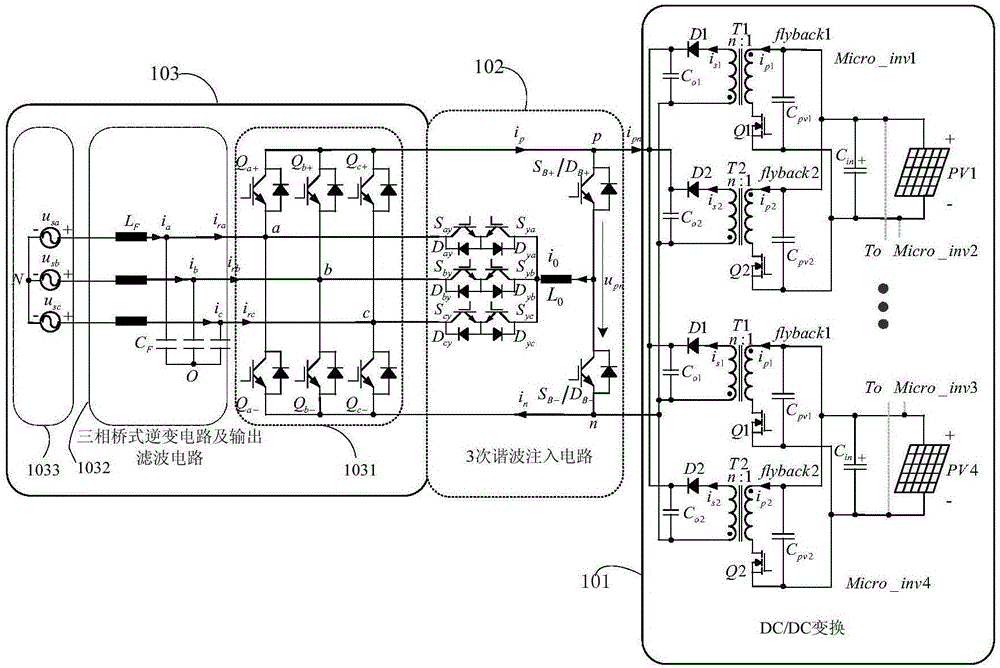

[0072] Such as figure 1 As shown, it is a schematic structural diagram of a high-efficiency and wide-load range three-phase micro-inverter provided by the present invention, including a front-stage module 101, an intermediate-stage module 102, and a rear-stage module 103 connected in sequence;

[0073] The front-end module is a photovoltaic power optimization module, which is used to transmit the electric energy output by the photovoltaic module and track the maximum power point of the photovoltaic module;

[0074] The intermediate module is a quasi-third harmonic injection circuit, which is used to output quasi-third harmonic injection current;

[0075] [The quasi-third harmonic injection current is the quasi-triangular wave current;]

[0076] The post-stage module 103 includes a three-phase bridge inverter circuit 1031, a three-phase filter circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com