Power storage device, method for producing same, and device for producing same

A technology for electric storage equipment and manufacturing devices, which is applied in the directions of packaging capacitor devices, terminal application devices, and final product manufacturing, and can solve the problems of film capacitor operation efficiency reduction, change, and tediousness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Hereinafter, in order to describe the present invention more concretely, embodiments of the present invention will be described in detail with reference to the drawings.

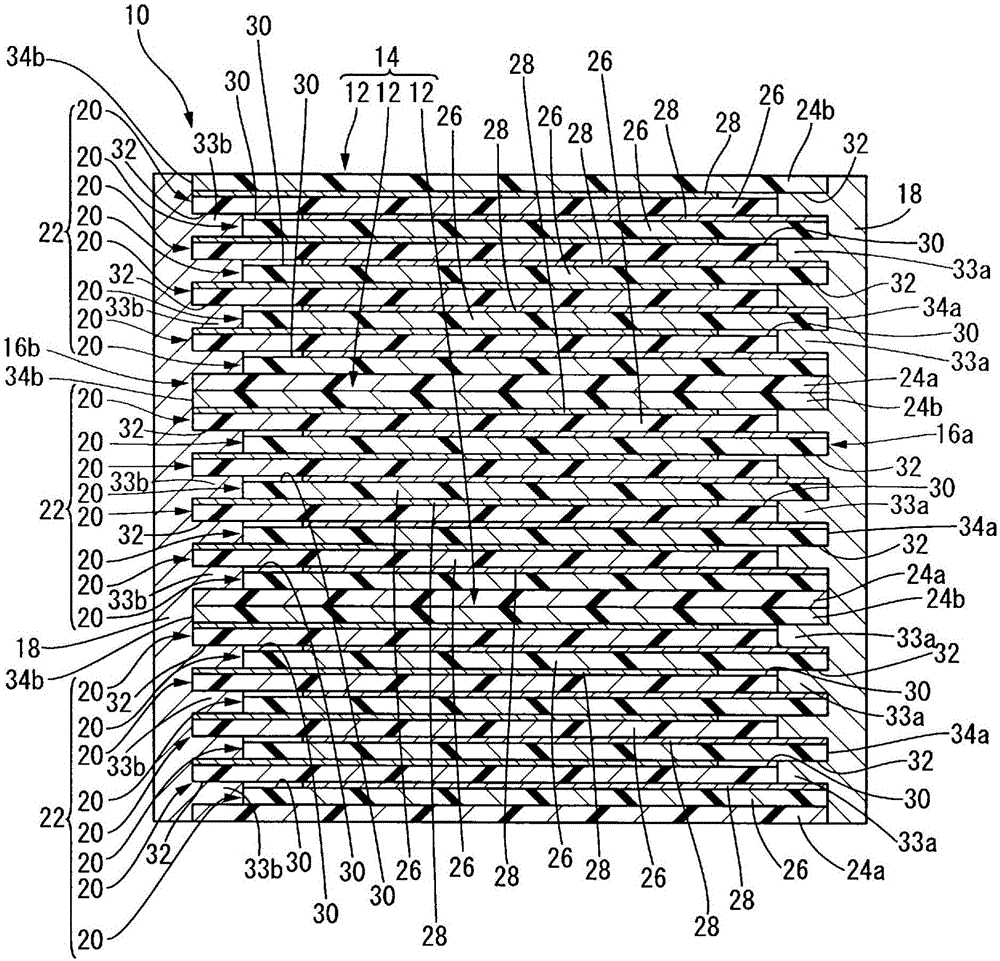

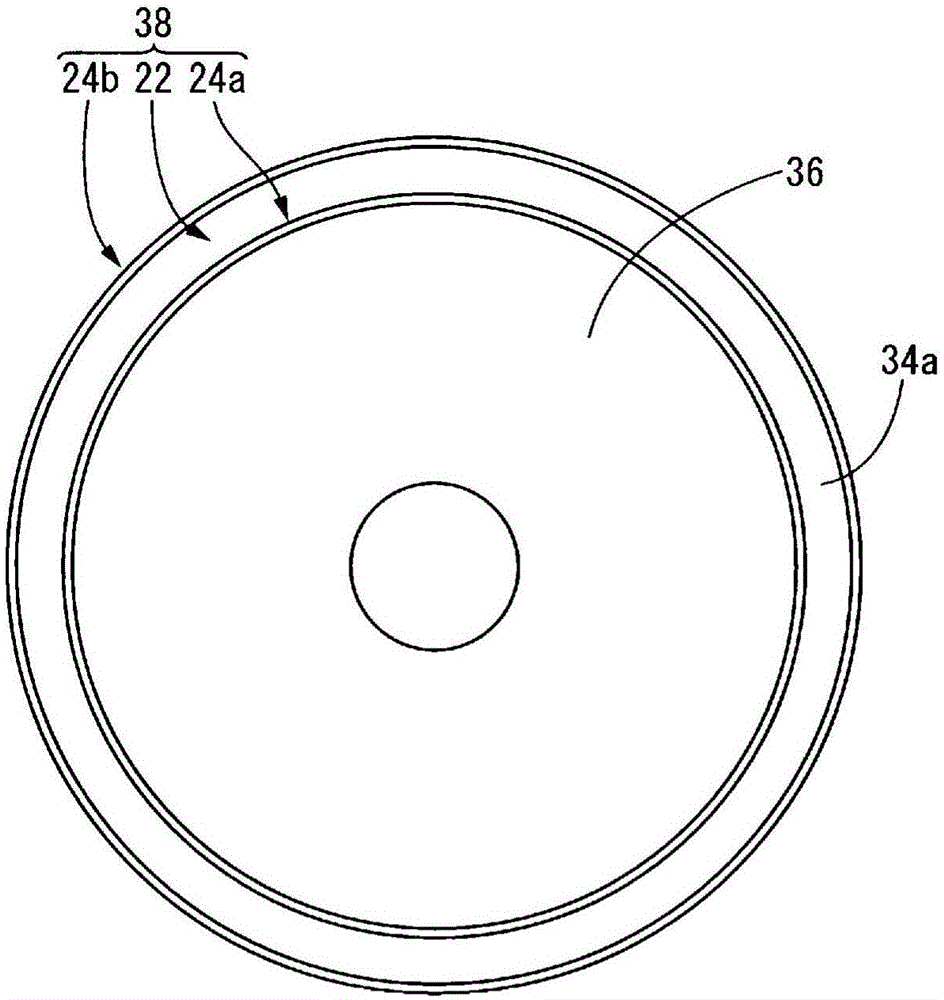

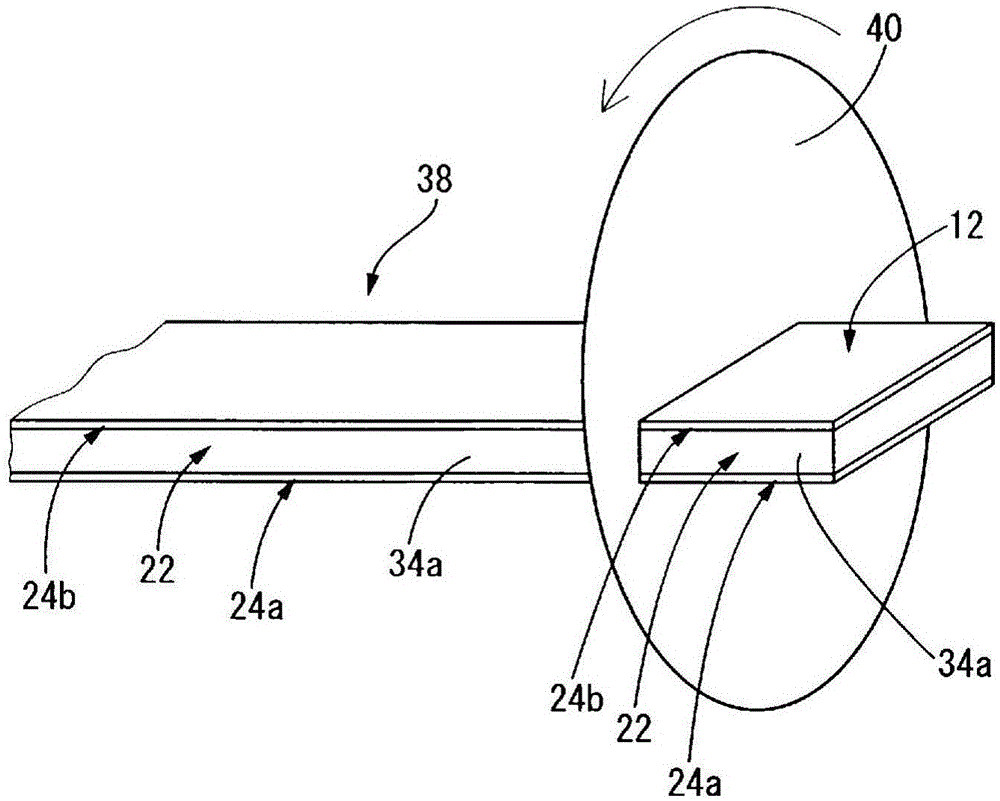

[0082] first, figure 1 A vertical cross-sectional form of a film capacitor which is an embodiment of an electrical storage device having the structure of the present invention is shown in . by the above figure 1 It can be seen that the film capacitor 10 of the present embodiment has three film capacitor elements 12 as electricity storage elements. Furthermore, the structure is as follows: These three thin film capacitor elements 12, 12, 12 are stacked on each other to form a laminated body 14, and on two side surfaces 16a, 16b corresponding to each other in the direction perpendicular to the stacking direction of the laminated body 14, the three film capacitor elements 12, 12, 12 are formed respectively. Metallized electrodes 18 as external electrodes.

[0083] More specifically, the thin film capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com