Blade knife pre-cutting type banana stem shattering and returning machine

A technology of banana stalks and paddles, applied in cutters, harvesters, crop processors, etc., can solve the problems of low efficiency of crushing and returning banana stalks to the field, filament winding, etc., achieving novel structure, less filament winding, preventing The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

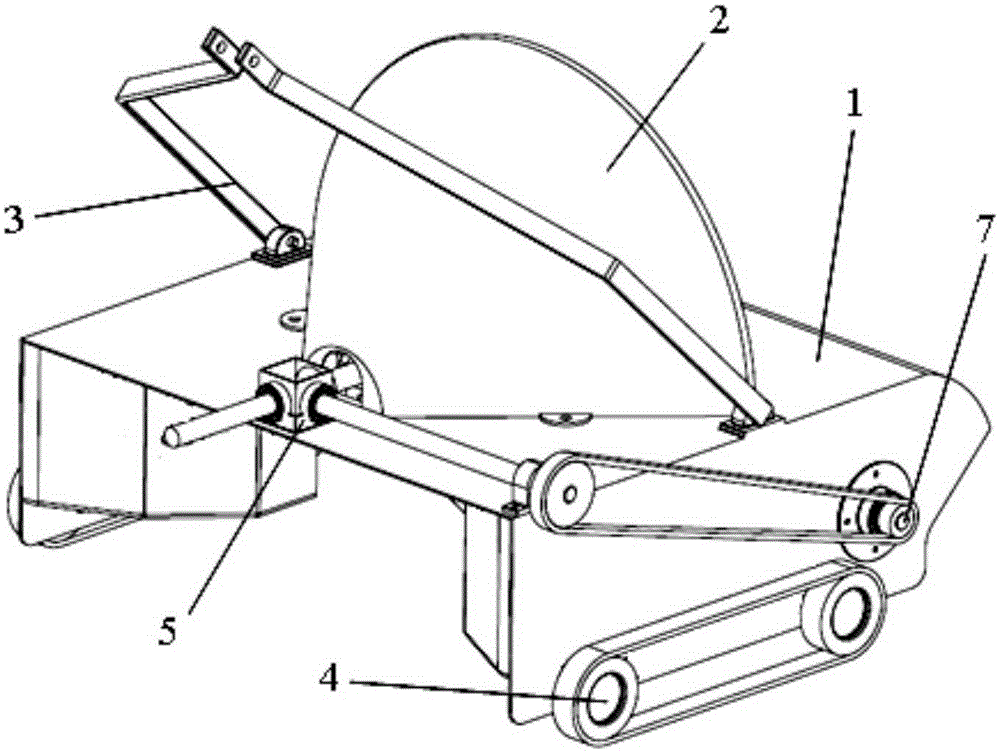

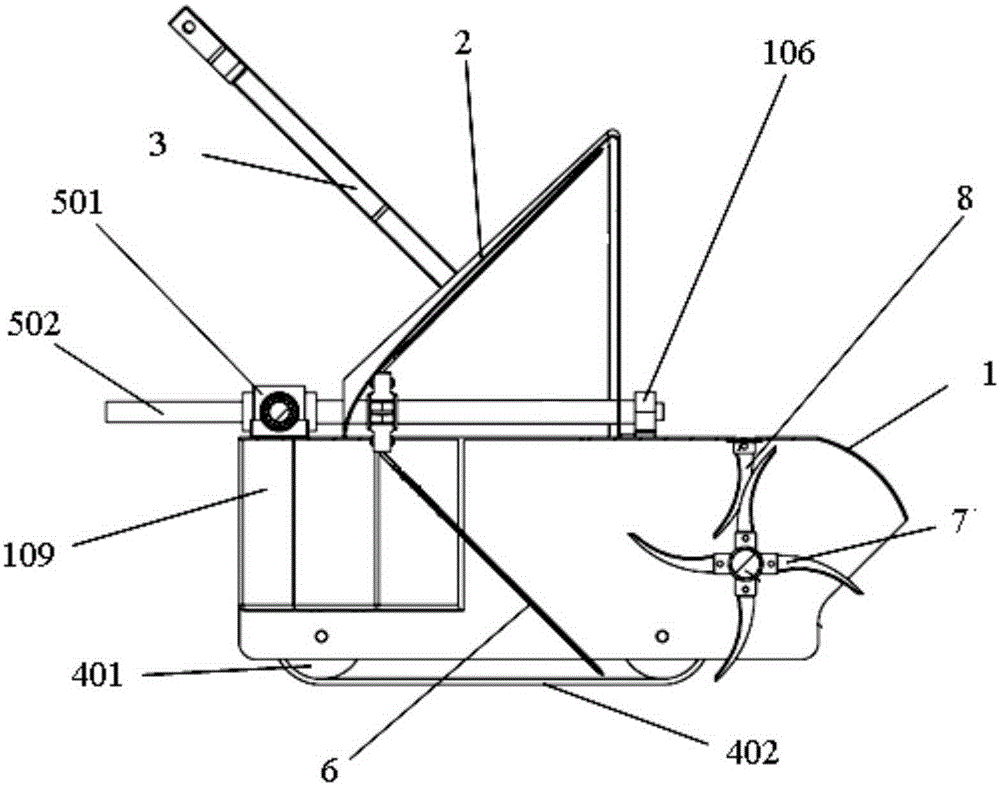

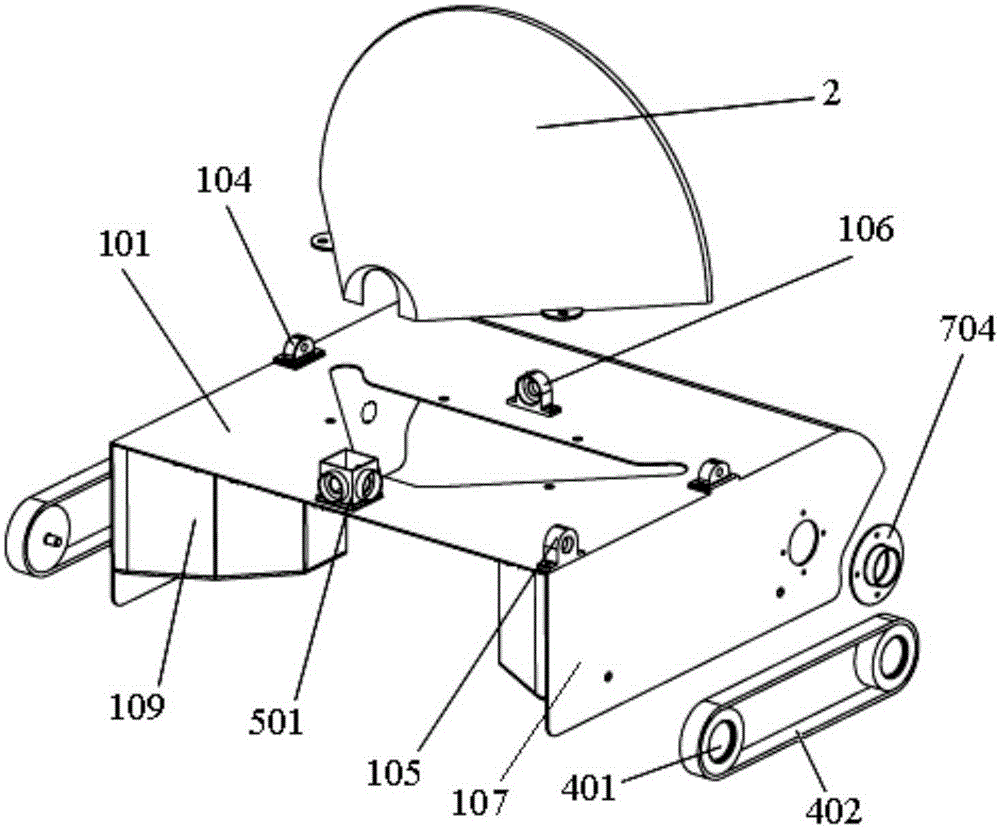

[0040] Such as figure 1 The three-dimensional structure diagram of the paddle knife pre-cut banana stem crushing and returning machine, figure 2 The left sectional view and the image 3 As shown in the exploded diagram of the basic structure of the paddle-knife pre-cut banana stem crushing and returning machine, the paddle-knife pre-cutting banana stem crushing and returning machine consists of a hook device, a paddle knife pre-cutting device, It consists of crushing device and traveling device. Among them, the crushing device is composed of a hob device and a fixed knife device, such as Figure 7A shown. The paddle knife pre-cut banana stalk crushing and returning machine is connected to the tractor through the hook device on the frame. The cutting device completes the pre-segmentation of the banana stalks, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com