A gating system for hollow single crystal blades

A single crystal blade and pouring system technology, applied in casting molding equipment, casting molds, cores, etc., can solve problems such as failure to ensure timely delivery of blades, failure to meet technical requirements, crystal orientation deviation, etc., to shorten the development cycle and reduce Economic loss, effect of reducing inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

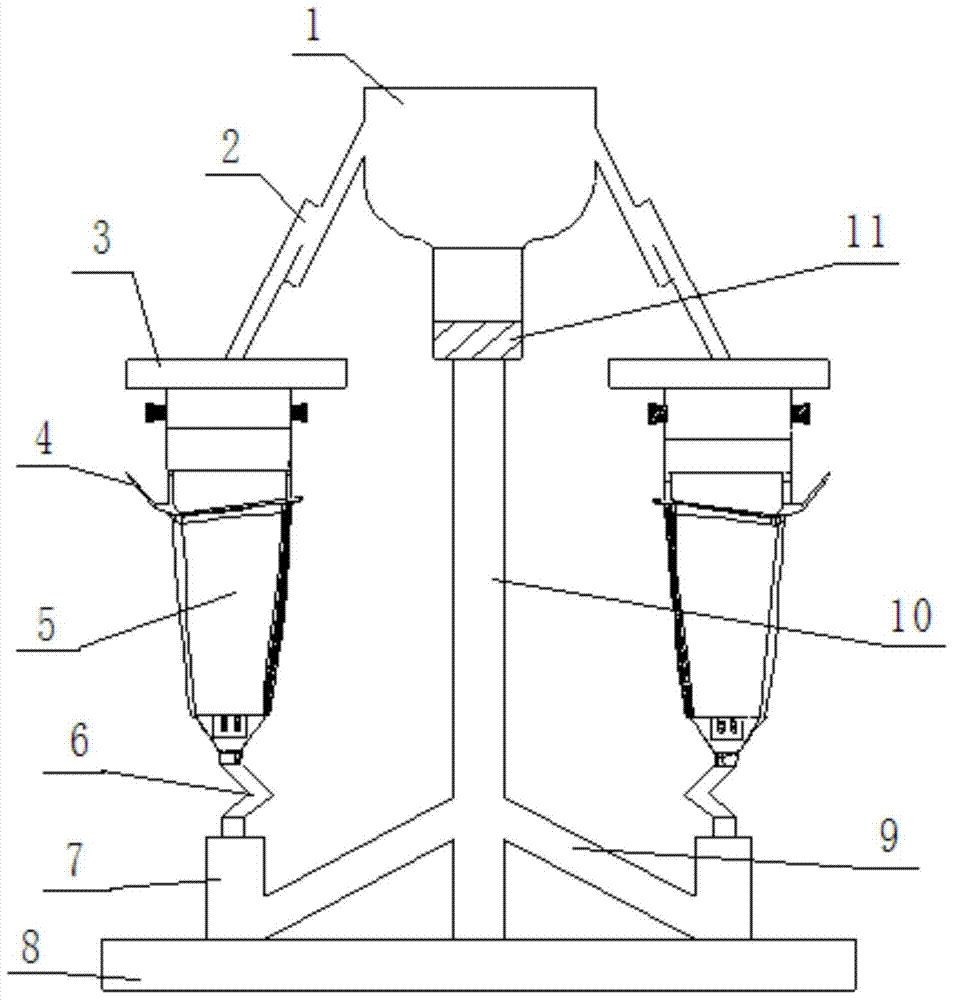

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0018] Such as figure 1 As shown, a gating system for a hollow single crystal blade according to the present invention includes a sprue cup 1, a feeding rectangular block 3, a blade wax piece 5, a seeding segment 7, a disc 8 and a sprue 10 , the sprue 10 and the seeding segment 7 are installed vertically on the disc 8 respectively, the upper end of the sprue 10 communicates with the sprue cup 1 through the ceramic filter 11, and the lower end communicates with the seeding segment through the ingate 9 7, the seeding segment 7 communicates with the lower end of the blade wax piece 5 through the spiral crystal selector 6, and the upper end of the blade wax piece 5 communicates with the feeding rectangular block 3, and the feeding shrinking rectangular block 3 is exhausted through the slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com