Special-purpose welding machine for welding electronic key plug devices

An electronic key and welding machine technology, applied in electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of complex processing flow and high requirements for manual technical level, and achieve the effect of improving work efficiency, facilitating processing, and preventing excessive temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

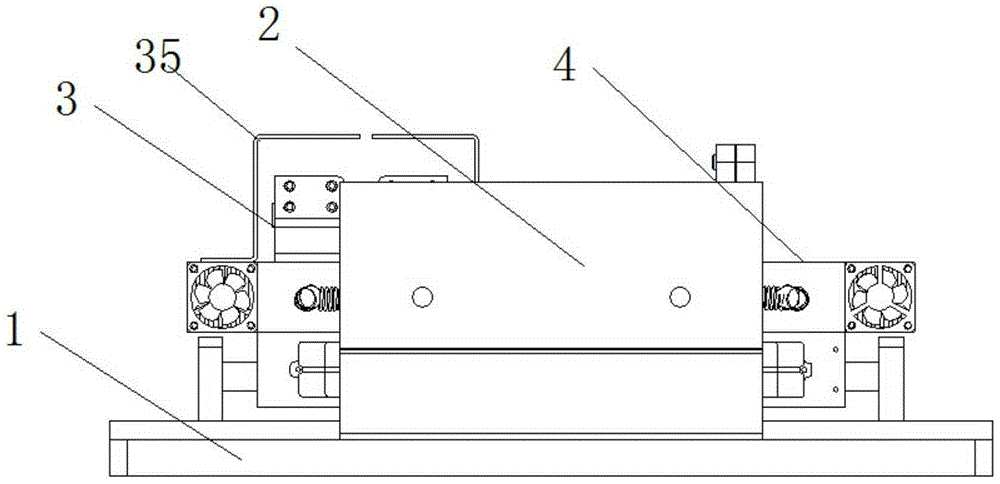

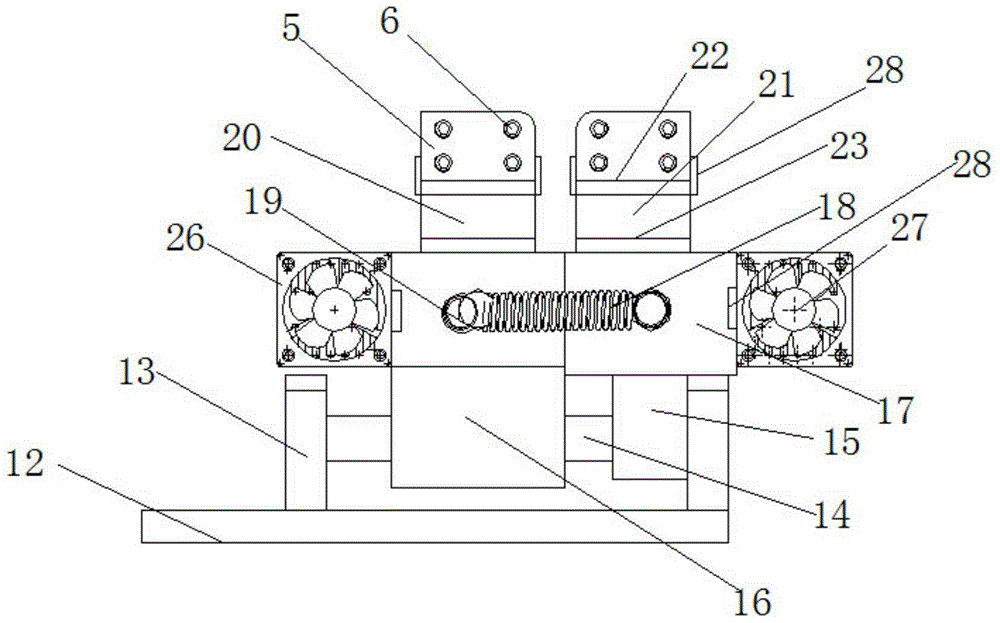

[0045] A special welding machine for welding an electronic key plug device, comprising an installation base plate 1 and a controller 2, and two ends of the installation base plate 1 are respectively provided with a heating module 3 and a heat dissipation module 4;

[0046] The heating module 3 includes two sets of heat conduction blocks 5, the heat conduction blocks 5 are horizontally arranged at intervals, and multiple sets of heating rods 6 are evenly arranged inside the heat conduction block 5;

[0047] When in use, the heating rod 6 is arranged inside the heat conducting block 5, which can increase the surface temperature of the heating block 5;

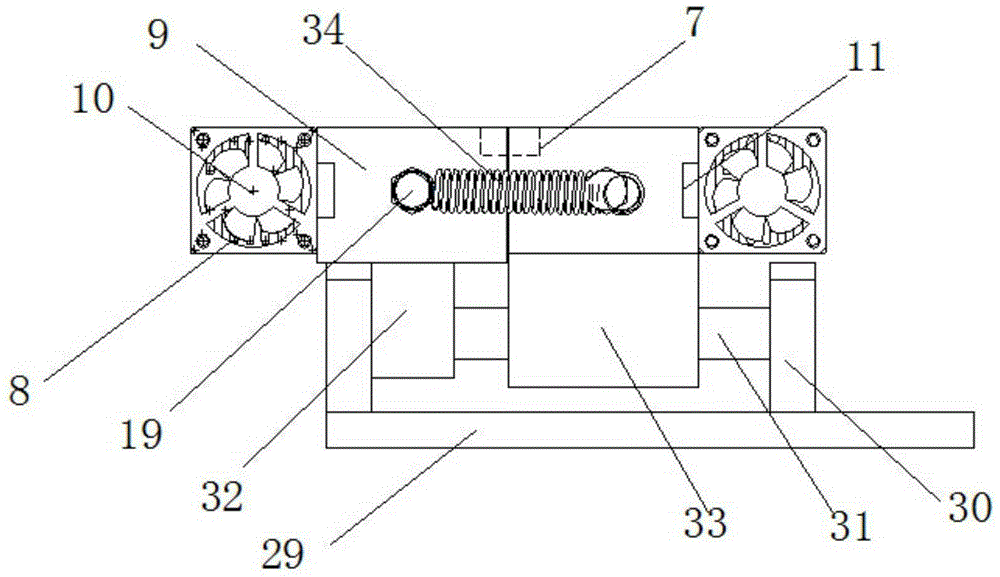

[0048] Wherein, the heating module 3 also includes a sliding platform bottom plate 12 and two supporting plates 13, the supporting plates 13 are installed on the sliding platform bottom plate 12 at intervals, and a guide rail 14 is connected between the supporting plates 13, One end of the guide rail one 14 is equipped with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com