Laser marking device of semiconductor chip

A technology of laser marking and laser marking machine, which is applied in the direction of semiconductor devices, laser welding equipment, circuits, etc. The effect of controllable range, reduced photographic field of view, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

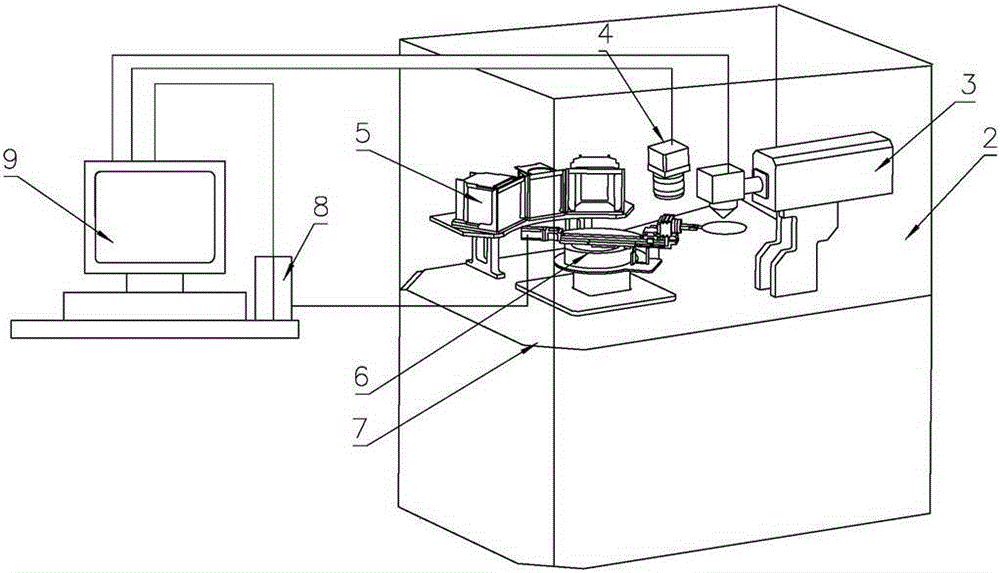

[0014] Depend on figure 2 Schematically, the present invention mainly includes: a frame 7, a marking room 2, a laser marking machine 3, a manipulator movement mechanism 6, a bin mechanism 5, a computer 9, and a motion controller 8, wherein the laser marking machine 3 passes through a control line The cable is connected to the computer 9, the camera 4 is connected to the computer 9 through the control cable, the manipulator movement mechanism 6 is connected to the motion controller 8 through the control cable, the computer 9 is connected to the motion controller 8 through the control cable, and the laser Marking machine 3, camera 4, manipulator movement mechanism 6 and silo mechanism 5 are all fixed on frame 7, and laser marking machine 3, camera 4, manipulator movement mechanism 6 and hopper mechanism 5 are placed in marking room 2 Inside, the laser marking machine 3 is located above the highest movement position of the mechanical arm in the manipulator movement mechanism 6, ...

Embodiment 2

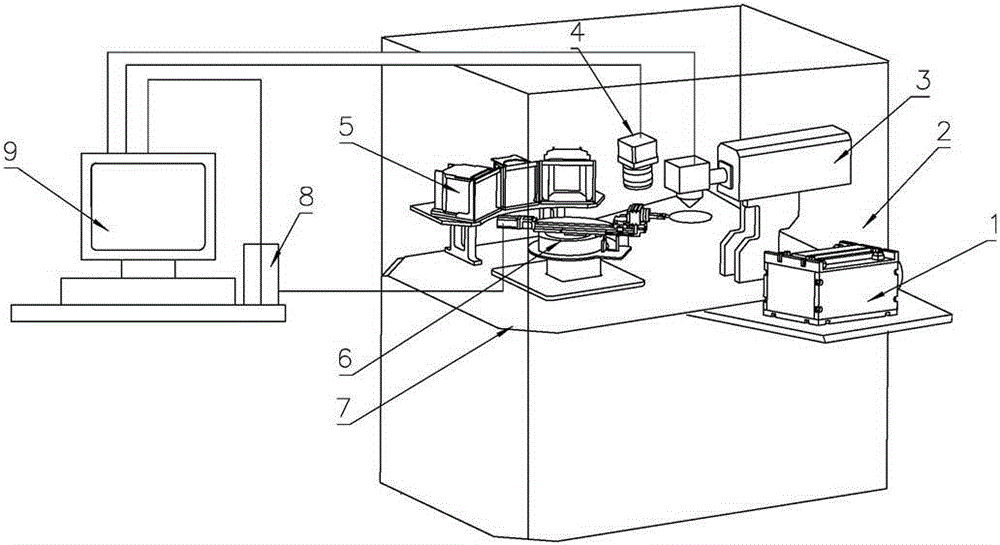

[0017] like image 3 Schematically, the difference between this embodiment and Embodiment 1 is that a leveler 1 is installed, the leveler 1 is fixed on the frame 7, and placed outside the marking room 2, and the others are the same as in Embodiment 1.

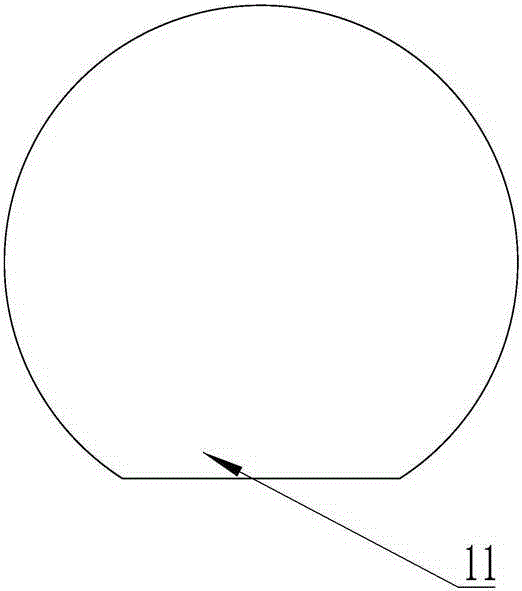

[0018]The leveler 1 is used to positively film a box of semiconductor wafers. When in use, the magazine containing the semiconductor wafers is placed on the leveler 1 on the mounting surface on the same side as the rotating roller, and semiconductor wafers 11 of different sizes The mounting surface on which the box is placed is also different. Through the rotation of the rotating roller on the leveler 1, when the short flat chord side of the semiconductor wafer in the magazine is tangent to the rotating roller, the semiconductor wafer in the magazine is in a static state and is ready to be processed. When all the semiconductor wafers in the box were at rest, the short flat chord sides of the semiconductor wafers 11 in the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com