Hybrid power multi-shaft rotor wing unmanned aerial vehicle

A rotary-wing unmanned and hybrid technology, applied in the field of unmanned aerial vehicles, can solve the problems such as the inability of the oil and electric power to back up each other, the complex structure, the uncontrolled fall of the aircraft, etc., so as to improve the safety of the whole machine, good safety, and long flight time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

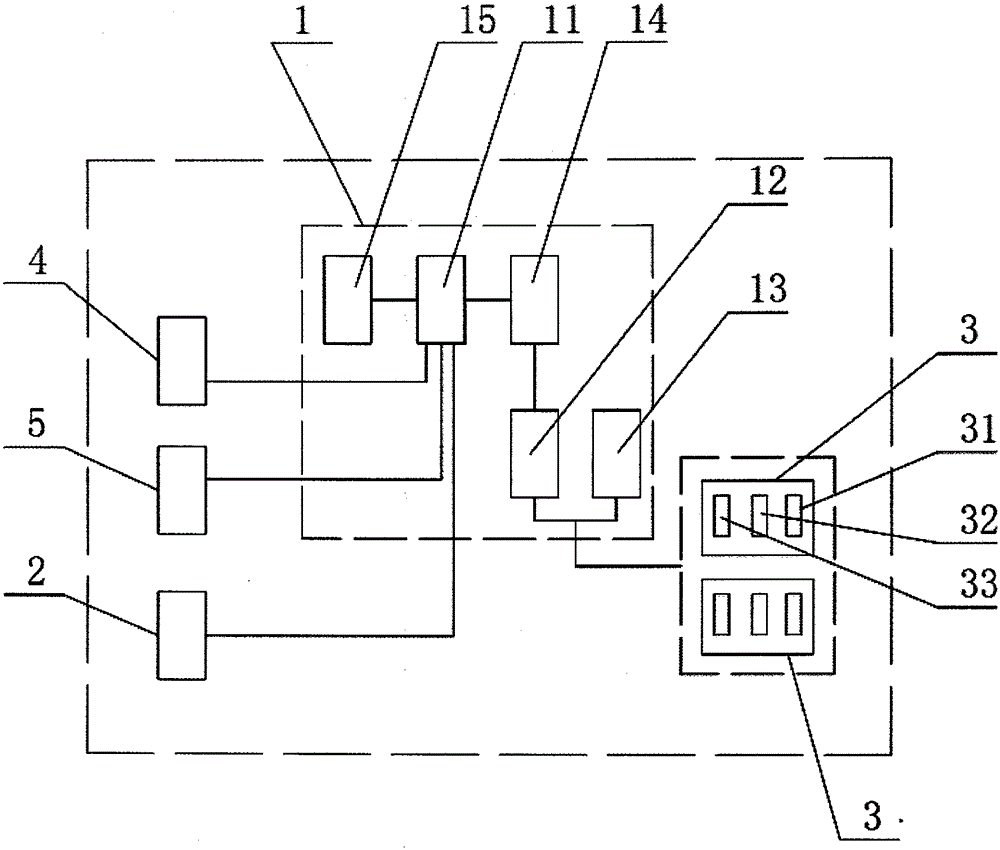

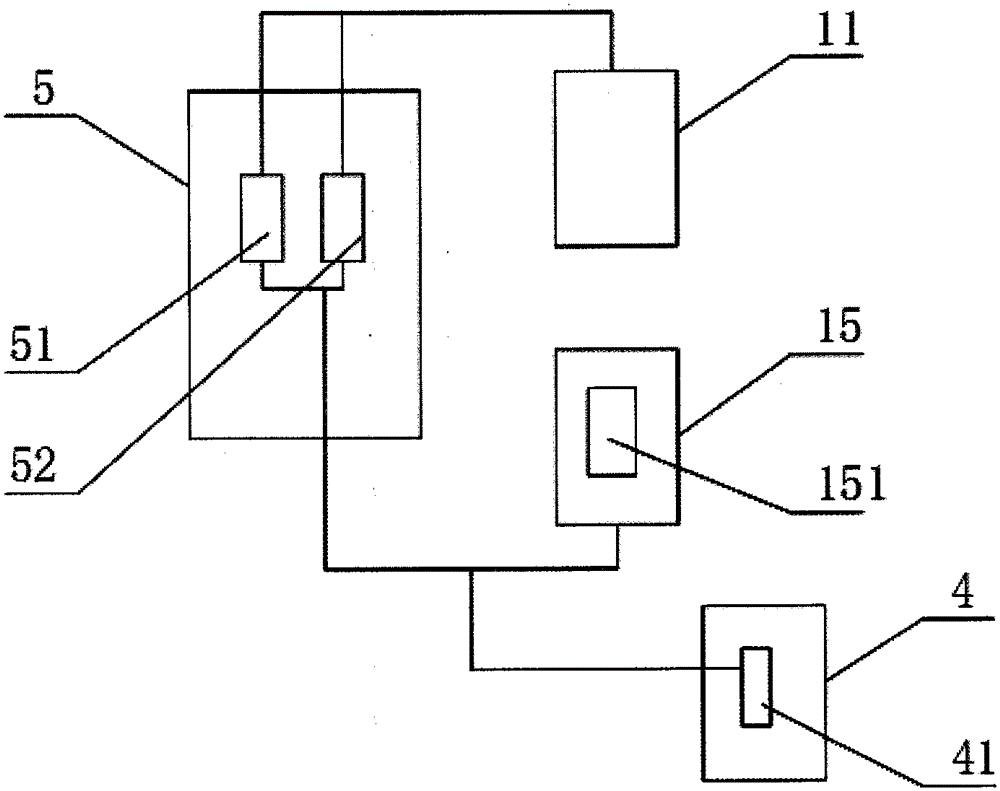

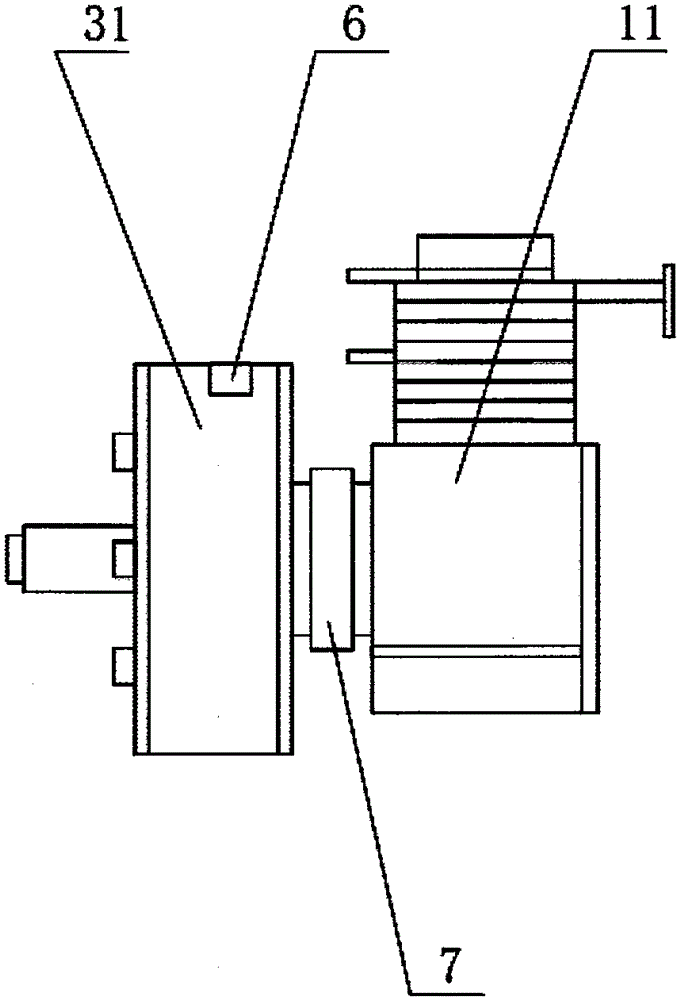

[0020] Such as figure 1 As shown, a hybrid multi-axis rotor UAV described in the present invention includes a UAV body, and the UAV body includes a flight control system 2 and a multi-axis drive system arranged in the casing. It also includes a fuel-electric hybrid system 1, a servo module 5 and a measurement and control module 4; the fuel-electric hybrid system 1 is composed of a fuel piston engine 11, a fuel tank 15, a power generation module 14, a rectification module 12 and a lithium battery 13; the fuel piston One end of the engine 11 is connected to the fuel tank 15 through an oil pipe, the other end of the fuel piston engine 11 is connected to the servo module 4, the output shaft of the fuel piston engine 11 is connected to the power generation module 14, and the power generation module 14 is connected to one end of the rectification module 12. The rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com