Six-freedom-degree zero-gravity simulation system based on combination of hoisting and air-suspending

A simulation system and degree-of-freedom technology, applied in the aerospace field, can solve the problems of lack of microgravity and low-gravity simulation equipment technology, and achieve the effects of compact structure, elimination of component vibration, and reduction of damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

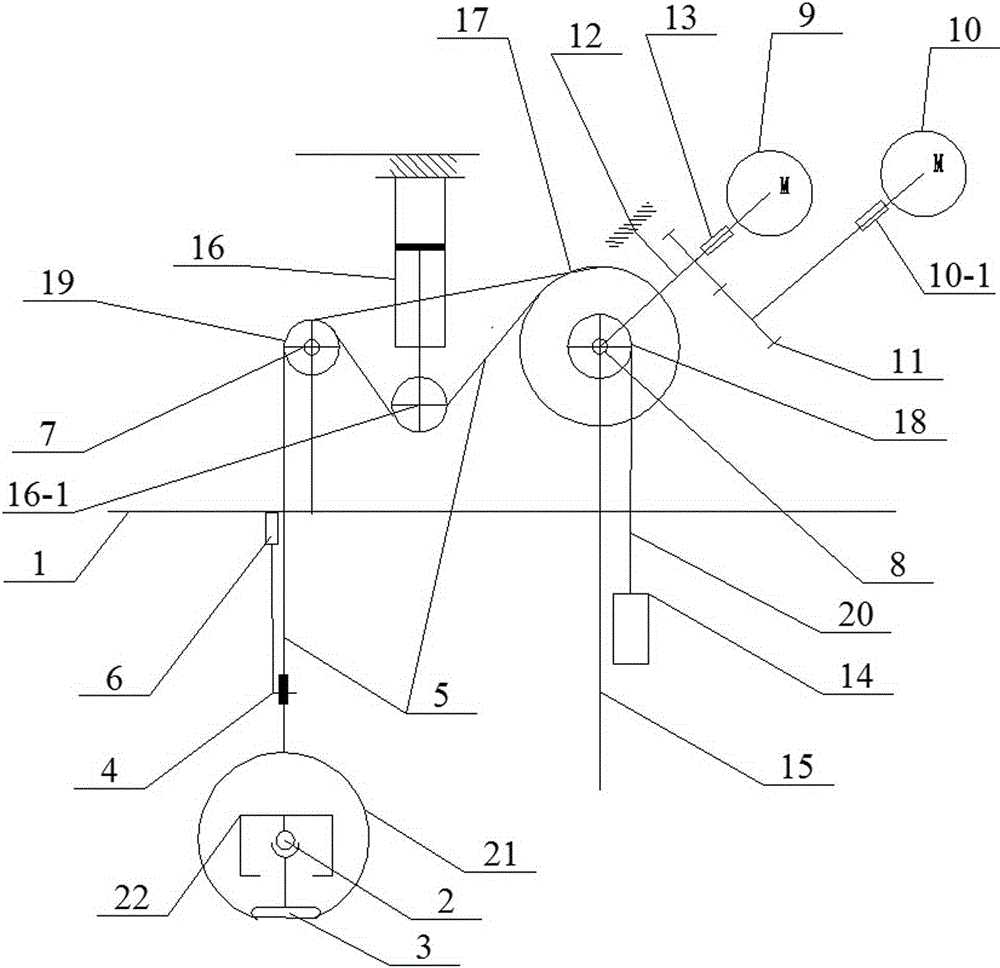

[0009] Specific implementation mode one: combine figure 1 As shown, it includes base 1, spherical air bearing 2, air tank 3, reflector 4, first sling rope 5, laser and light detection assembly 6, first group of air bearing 7, second group of air bearing 8 , balance motor 9, lifting motor 10, clutch 11, brake 12, torque sensor 13, counterweight 14, air bearing guide rail 15, frictionless cylinder 16, large diameter reel 17, small diameter reel 18, pulley 19, the first Two sling ropes 20, the workpiece platform 21 to be tested;

[0010] One end surface of the large-diameter reel 17 is coaxially connected with an end surface of the small-diameter reel 18; the shaft at the other end of the large-diameter reel 17 and the shaft at the other end of the small-diameter reel 18 pass through the second set of air bearings 8 Rotatingly installed on the base 1, the output shaft of the balance motor 9 is connected to one end of the torque sensor 13, the output shaft of the lifting motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com