Treatment method of phenolic wastewater in production of sebacic acid

A treatment method, sebacic acid technology, is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high treatment cost, large energy consumption, and large equipment investment. Achieve the effects of reduced processing cost, reduced investment in extraction process, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

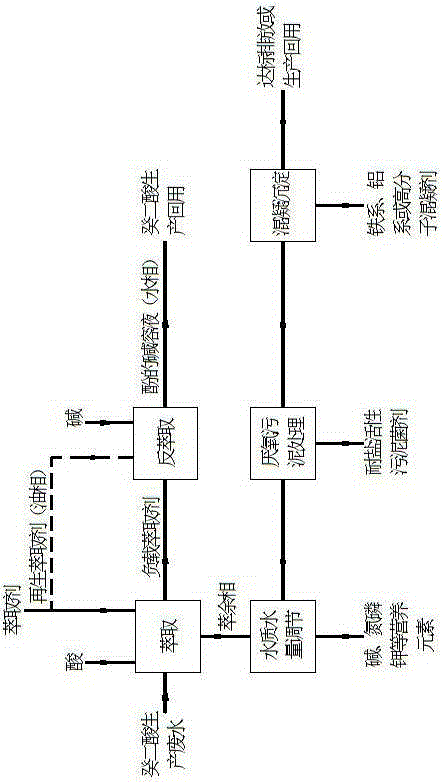

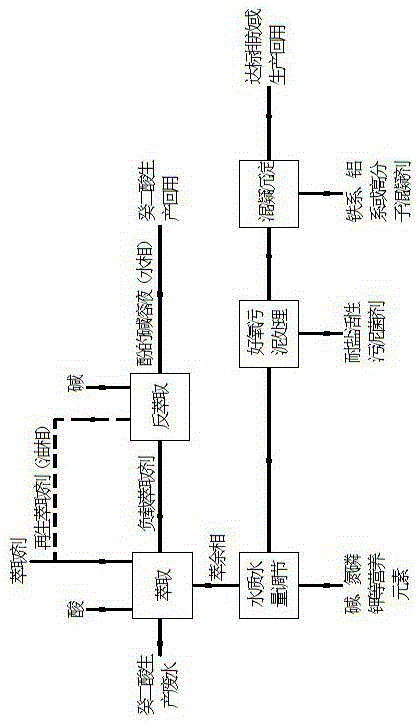

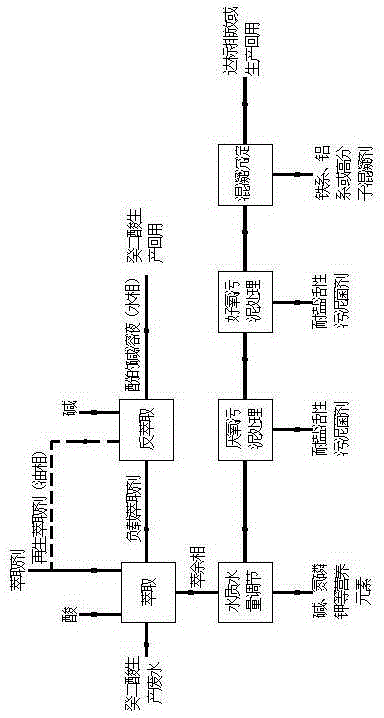

[0033] Example 1, a treatment method for phenol-containing wastewater in the production of sebacic acid: the high-salt phenol-containing wastewater in the production of sebacic acid is first extracted with an extractant to remove phenol, and then biochemically treated with salt-suitable microorganisms to make the COD in the wastewater Cr and volatile phenols up to the standard, while recovering phenolic substances in the wastewater; the extractant is selected from at least one of phosphoric acid esters, alkylamines, castor oil, kerosene or diesel or a mixture thereof.

Embodiment 2

[0034] Example 2, in the treatment method of phenol-containing wastewater in the production of sebacic acid described in Example 1: extraction means that the wastewater and the extractant are fully mixed at a ratio of 0.5:1 to oil and water, and the pH of the mixture of the extractant and the wastewater is adjusted The value is 2; then the mixture is left to stand and stratified. The extracted phase after stratification is the loaded extractant and sent to the stripping process for regeneration. The raffinate phase after stratification is neutralized in water after extraction to a pH of 6. deal with.

Embodiment 3

[0035] Example 3, in the treatment method of phenol-containing wastewater in the sebacic acid production described in Example 1: extraction refers to fully mixing the wastewater with the extractant at a ratio of 4:1 to oil and water, and adjusting the pH of the mixture of the extractant and the wastewater The value is 3; then the mixture is allowed to stand and stratified. The extracted phase after stratification is the loaded extractant and sent to the stripping process for regeneration. The raffinate phase after stratification is neutralized in water after extraction to a pH of 9. deal with.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com