Steel fiber/fly ash/red mud water-permeable brick and preparation method thereof

A steel fiber and permeable brick technology is applied in the field of infrastructure materials to achieve the effects of improving living conditions, good water permeability and alleviating the urban heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

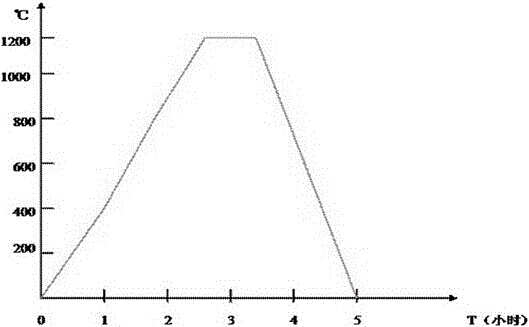

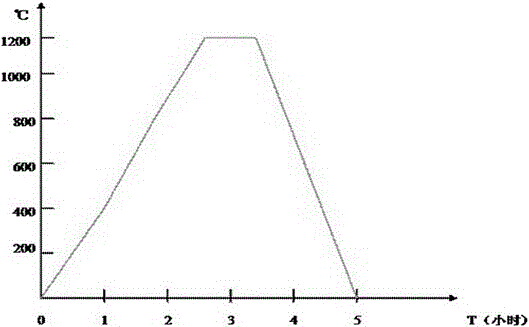

[0023] A preparation method of steel fiber fly ash red mud permeable brick: obtained by the following steps:

[0024] (1) Raw material mixing: Weigh the following raw materials by weight: steel fiber: 50-70, red mud 15-20, fly ash 20-30, brick slag particles 30-40; the steel fiber length is 30-40mm , with a diameter of 0.3-0.4mm; the brick slag is made of ordinary brick slag with a particle size of 5-8mm; these raw materials are mixed with water, and the moisture content is controlled at 15-25%;

[0025] (2) Forming: Input the mixed raw materials into the brick making machine to form the adobe;

[0026] (3) Conservation: Natural conservation, the ambient temperature is 5-35°C, and the conservation time is 3-5 days;

[0027] (4) Firing: firing, put the bricks into the kiln, increase the temperature of the furnace to 1000-1200°C at a heating rate of 350-400°C / h, keep it warm for 1-2 hours, and then naturally cool to room temperature to obtain Permeable bricks.

[0028] its si...

Embodiment 2

[0030] A preparation method of steel fiber fly ash red mud permeable brick: obtained by the following steps:

[0031] (1) Raw material mixing: Weigh the following raw materials by weight: steel fiber: 60, red mud 18, fly ash 25, brick slag particles 35; the steel fiber length is 35mm, and the diameter is 0.3mm; brick slag is made of ordinary bricks Slag, the particle size is 5-8mm; these raw materials are mixed with water, and the moisture content is controlled at 15-25%;

[0032] (2) Forming: Input the mixed raw materials into the brick making machine to form the adobe;

[0033] (3) Conservation: Natural conservation, the ambient temperature is 5-35°C, and the conservation time is 3-5 days;

[0034] (4) Firing: firing, put the bricks into the kiln, increase the temperature of the furnace to 1000-1200°C at a heating rate of 350-400°C / h, keep it warm for 1-2 hours, and then naturally cool to room temperature to obtain Permeable bricks.

Embodiment 3

[0036] A preparation method of steel fiber fly ash red mud permeable brick: obtained by the following steps:

[0037] (1) Raw material mixing: Weigh the following raw materials by weight: steel fiber: 70, red mud 20, fly ash 30, brick slag particles 40; the steel fiber length is 30-40mm, and the diameter is 0.3-0.4mm; The brick slag is made of ordinary brick slag with a particle size of 5-8mm; these raw materials are mixed with water, and the moisture content is controlled at 15-25%;

[0038] (2) Forming: Input the mixed raw materials into the brick making machine to form the adobe;

[0039] (3) Conservation: Natural conservation, the ambient temperature is 35°C, and the conservation time is 3 days;

[0040] (4) Firing: firing, put the bricks into the kiln, increase the temperature of the furnace to 1000-1200°C at a heating rate of 350-400°C / h, keep it warm for 1-2 hours, and then naturally cool to room temperature to obtain Permeable bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com