Modified desulphurization gypsum-based mater batch and preparation method therefor

A technology for desulfurized gypsum and desulfurized building gypsum is applied in the field of modified desulfurized gypsum-based masterbatch and its preparation, which can solve the problems of low cost and lack of high efficiency, and achieve the effects of reducing cost, low calcination temperature and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Modified desulfurization gypsum formula

[0065] Table 1

[0066] Desulfurization building gypsum

650 parts by weight

150 parts by weight

100 parts by weight

[0067] cement

100 parts by weight

0.65 parts by weight

1 part by weight

0.5 parts by weight

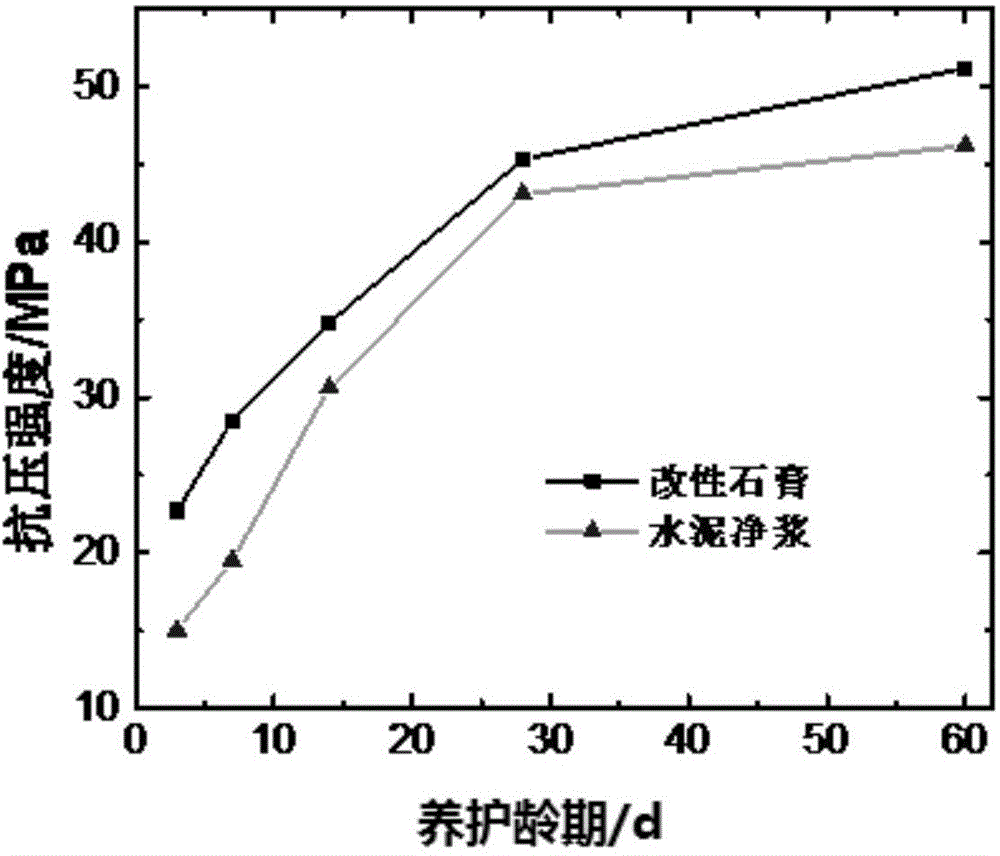

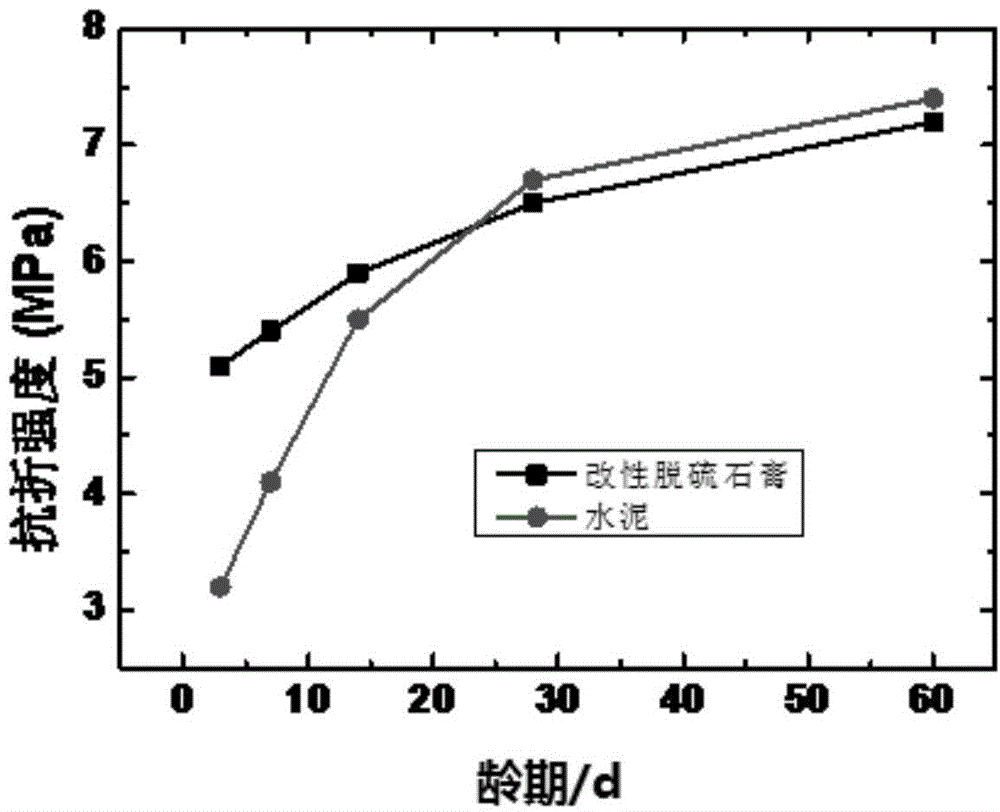

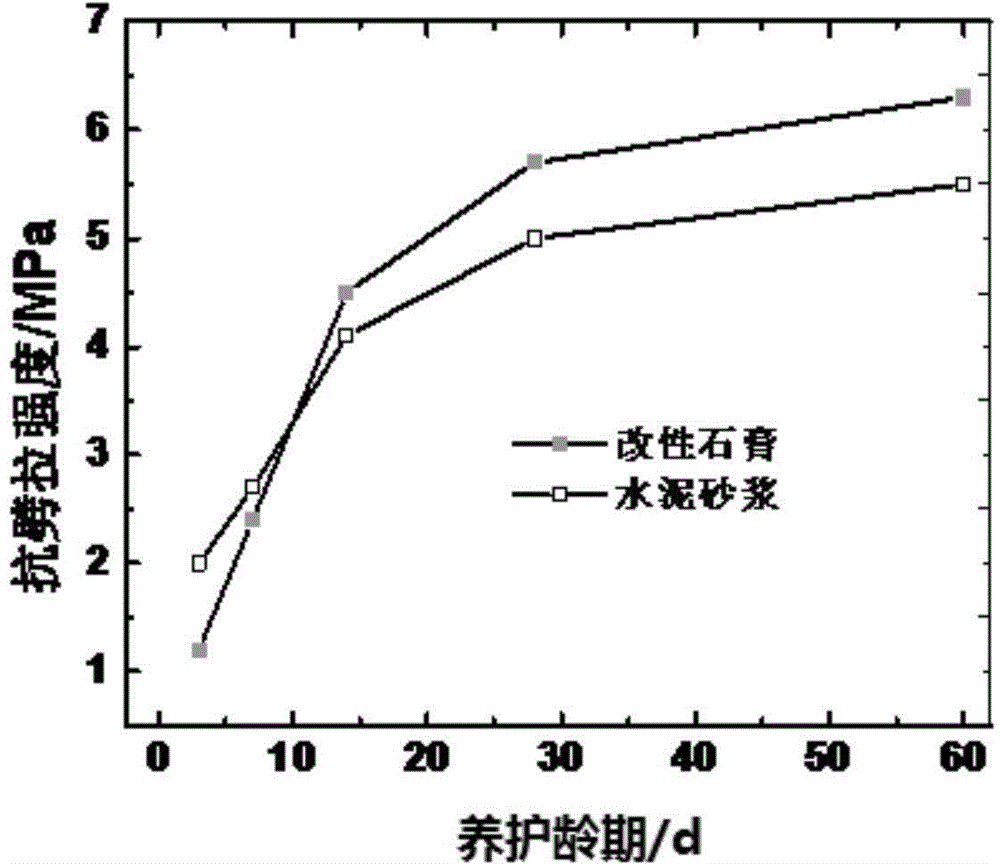

[0068] Mix the modified desulfurized gypsum according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0069] Table 2

[0070] performance parameter

Embodiment 2

[0072] Modified desulfurization gypsum formula

[0073] table 3

[0074] Desulfurization building gypsum

550 parts by weight

Slag powder

150 parts by weight

200 parts by weight

cement

100 parts by weight

0.55 parts by weight

1.5 parts by weight

0.5 parts by weight

[0075] Mix the modified desulfurized gypsum according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0076] Table 4

[0077]

[0078]

Embodiment 3

[0080] Modified desulfurization gypsum formula

[0081] table 5

[0082] Desulfurization building gypsum

500 parts by weight

Slag powder

150 parts by weight

fly ash

250 parts by weight

cement

100 parts by weight

1 part by weight

retarder

0.5 parts by weight

Polycarboxylate superplasticizer for gypsum

2 parts by weight

1 part by weight

[0083] Mix the modified desulfurized gypsum according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0084] Table 6

[0085] performance parameter

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com