Zero-carbon-emission alcohol-hydrogen power system and vehicle

A power system and alcohol-hydrogen technology, which is applied in the field of alcohol-water hydrogen production, can solve problems such as easy vibration, reduced service life of palladium tube, and damage to palladium film, so as to avoid friction, improve service life and prevent vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

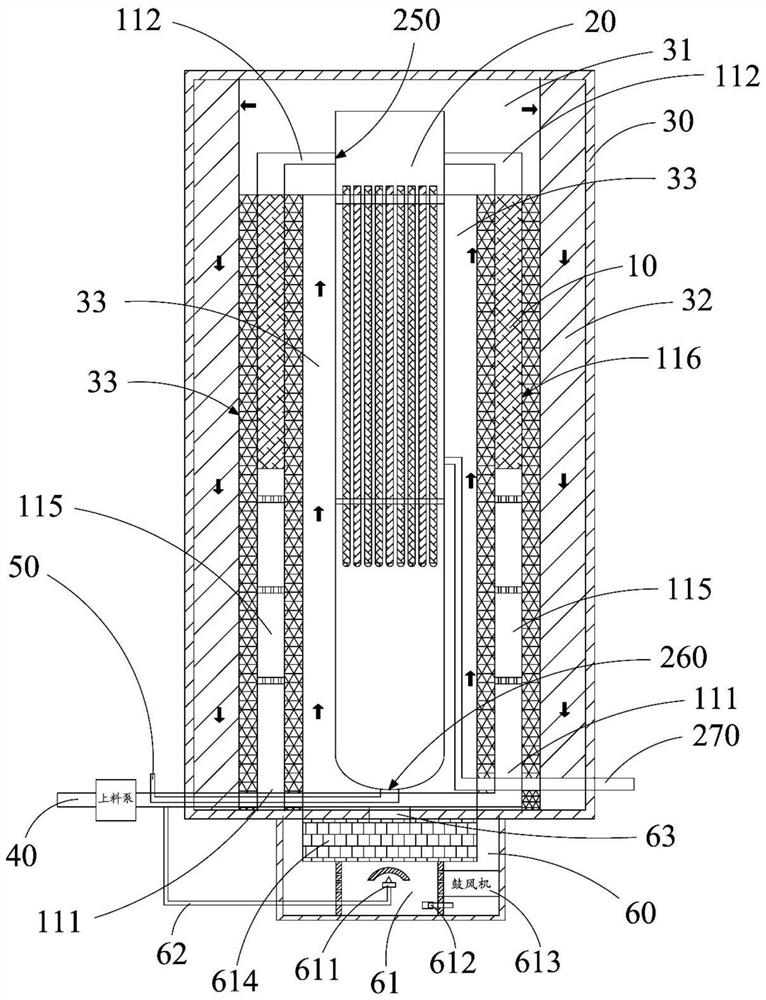

[0031] The present invention discloses a zero-carbon emission hydrogen alcohol power system, including a hydrogen stack module 100 for outputting purified hydrogen, a carbon collection module for recovering the carbon dioxide produced by the hydrogen stack module 100, and outputting the hydrogen stack module 100 The stack module that converts hydrogen into electricity.

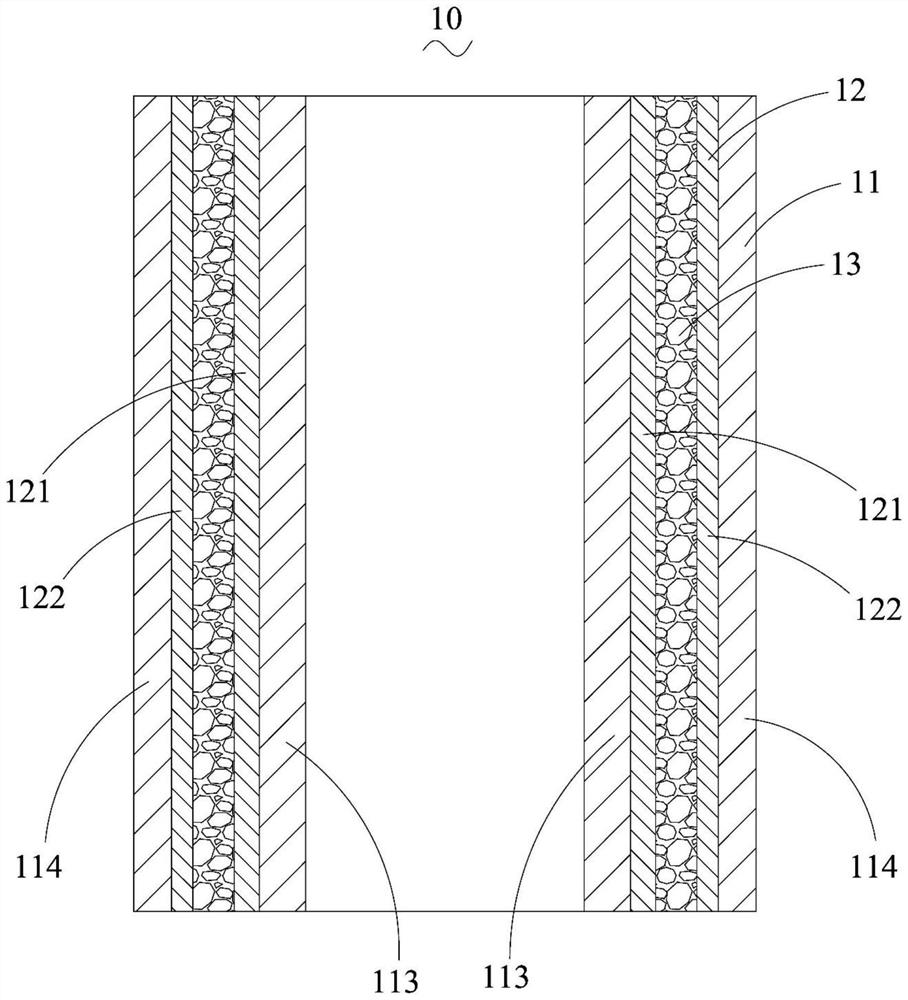

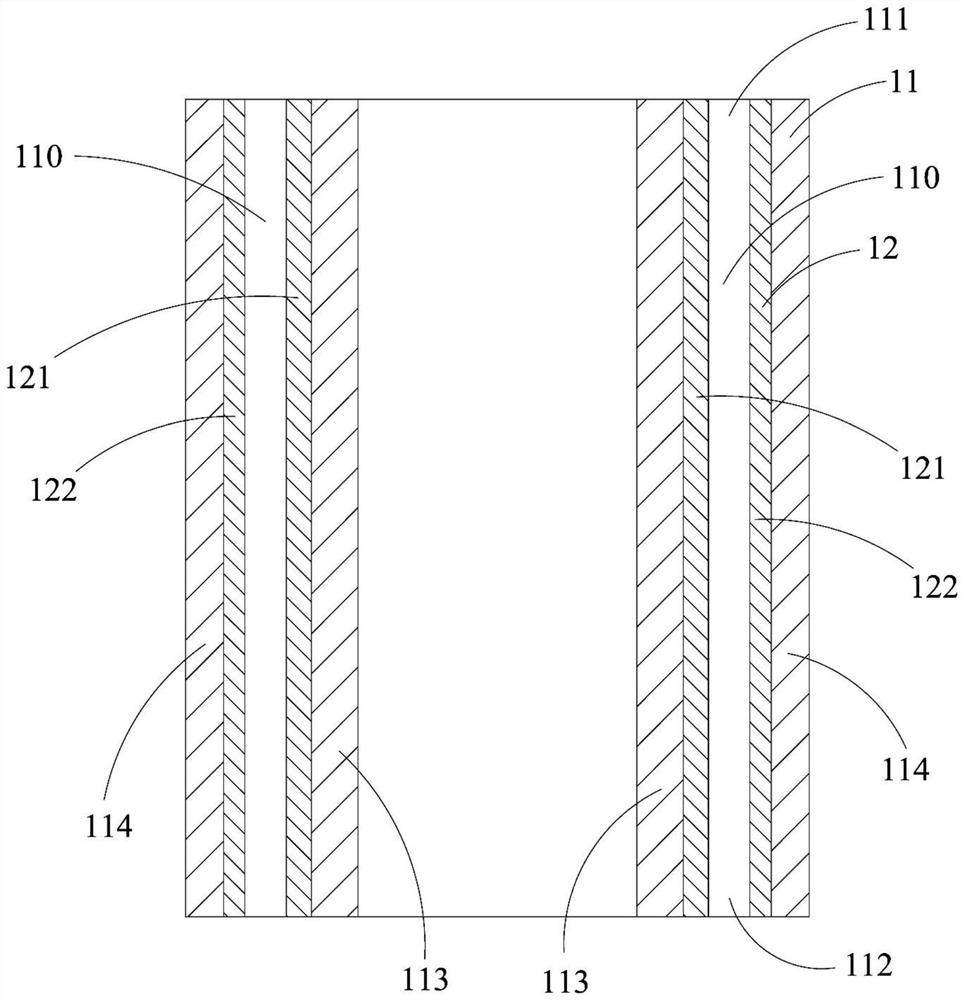

[0032] see figure 1 As shown, the hydrogen stack module 100 includes a reforming reaction assembly 10 for producing hydrogen through an alcohol-water reforming reaction, a palladium membrane assembly 20 communicating with the reforming reaction assembly 10, and accommodating the reforming reaction assembly 10 The outer casing 30 of the palladium membrane module 20, the feed pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com