Low thermal-conductivity high temperature glue and preparation method thereof

A high-temperature glue, low thermal conductivity technology, applied in the field of refractory materials, can solve the problems of narrow application range, high thermal conductivity, unfavorable thermal equipment energy saving and consumption reduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

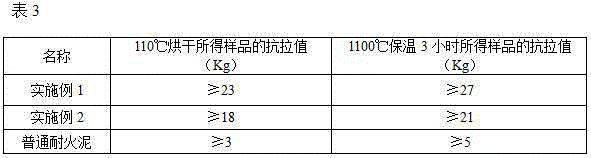

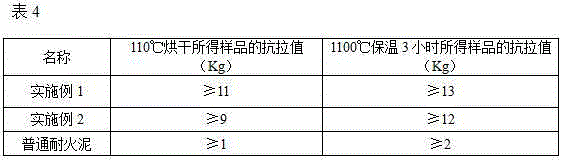

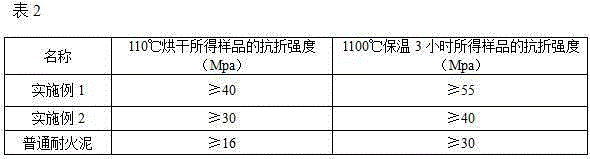

Examples

Embodiment 1

[0012] Raw material compatibility: in terms of mass percentage, 70% of synthetic mullite with a particle size of <0.074mm, 10% of alumina micropowder with a particle size of <0.074mm, 15% of silicon micropowder with a particle size of <0.045mm, and 5% of nano-ATO with a particle size of <20nm Add silica sol; wherein, the amount of silica sol is 45% of the sum of the mass of synthetic mullite, alumina micropowder, silica micropowder and nano-ATO.

[0013] Preparation method: Weigh each raw material in proportion, first place synthetic mullite, alumina micropowder, silica micropowder and nano-ATO in a closed mill for grinding, mix and co-mill until the average particle size is <0.02mm, then add silica sol and stir evenly That's it.

Embodiment 2

[0015] Raw material compatibility: In terms of mass percentage, 60% of synthetic mullite with a particle size of <0.074mm, 15% of alumina micropowder with a particle size of <0.074mm, 15% of silicon micropowder with a particle size of <0.045mm, and 10% of nano-ATO with a particle size of <20nm Add silica sol; wherein, the amount of silica sol is 50% of the sum of the mass of synthetic mullite, alumina micropowder, silica micropowder and nano-ATO.

[0016] Preparation method: Weigh each raw material in proportion, first place synthetic mullite, alumina micropowder, silica micropowder and nano-ATO in a closed mill for grinding, mix and co-mill until the average particle size is <0.02mm, then add silica sol and stir evenly That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com