Ventilation fermentation tank tail gas energy turbine reclaiming method

A ventilated fermenter and recovery method technology, applied in the field of biochemical engineering, can solve the problems of tail gas pressure energy and heat energy loss, and achieve low equipment cost, lower pressure and temperature, and better effects of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

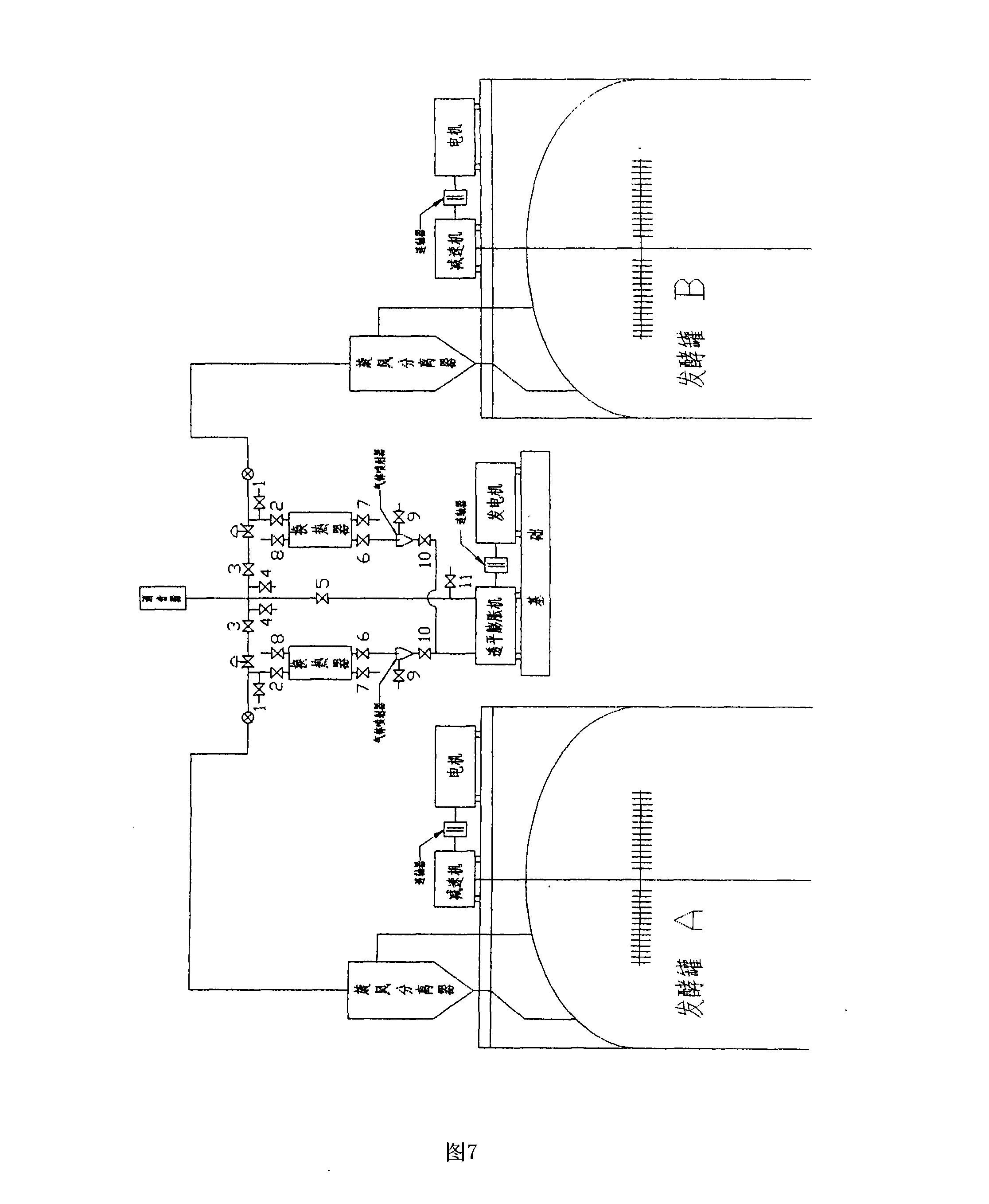

[0017] As shown in Figure 1: Two circuits are connected in parallel on the exhaust pipe of the fermentation tank. One circuit is connected to the heat exchanger and the turbo expander, and the other circuit is connected to the turbo expander at one end and the silencer at the other end. It is connected with the reducer through the coupling. The tail gas from the fermentation tank is introduced into the heat exchanger through valve control. After the tail gas is heated in the heat exchanger, it enters the turbo expander to directly perform work, converts heat and pressure energy into mechanical energy, and outputs the mechanical energy to the reducer to drive the fermentation tank to stir, and the turbine expands After the machine does work, the low-temperature and low-pressure gas is discharged through the valve into the muffler and discharged.

[0018] Close valve 3, lead the tail gas from the fermentation tank through the cyclone separator, enter the heat exchanger through valve...

Embodiment 2

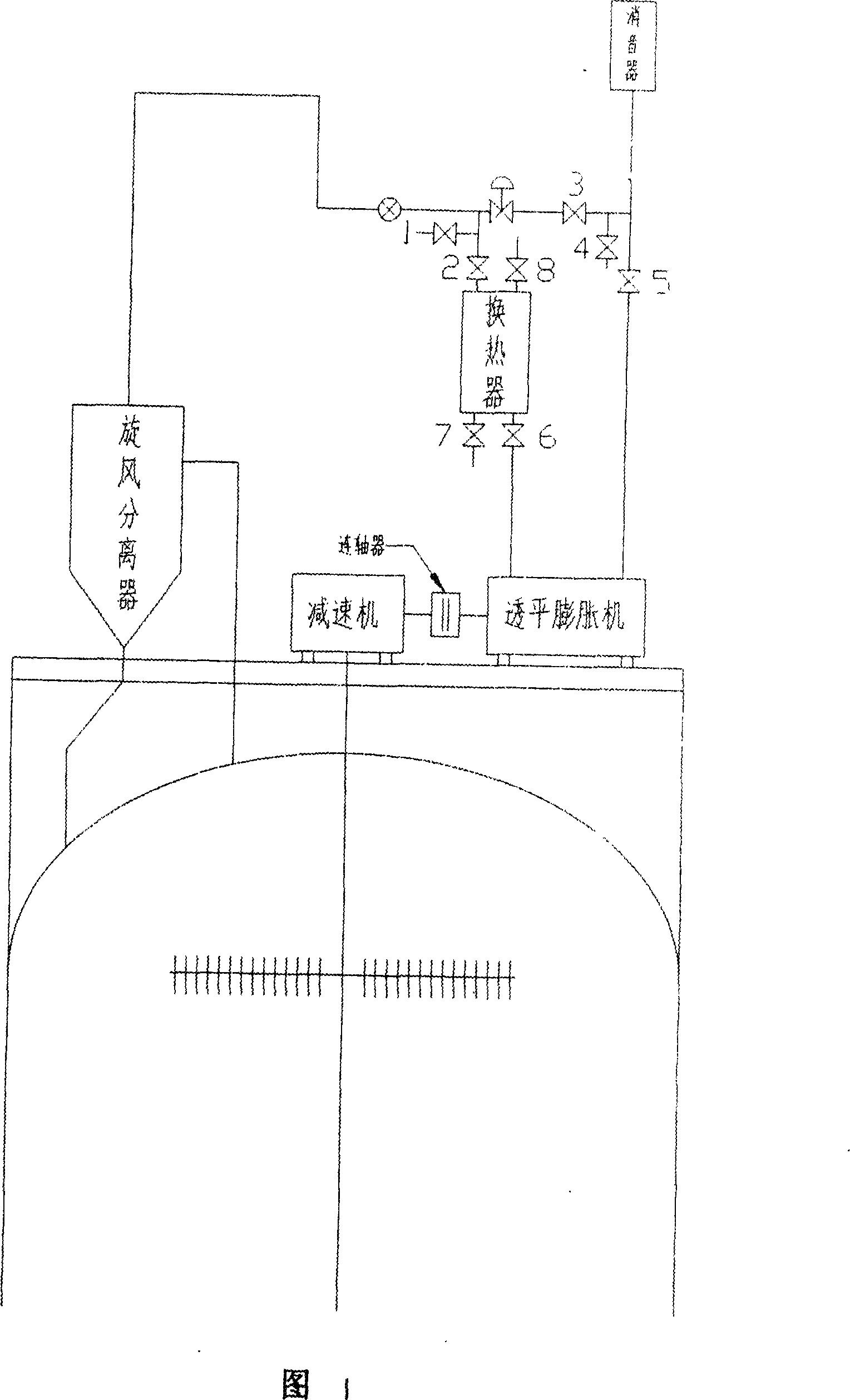

[0020] As shown in Figure 2: Two circuits are connected in parallel on the exhaust pipe of the fermentation tank. One circuit is connected to the heat exchanger and the turbo expander, and the other circuit is connected to the turbo expander at one end and the muffler at the other end. It is connected with the reducer through the coupling. The turbo expander and the reducer can be connected to the motor through a clutch. The tail gas of the fermentation tank is introduced into the heat exchanger through valve control. After the tail gas is heated in the heat exchanger, it enters the turbo expander to directly perform work. The pressure energy is converted into mechanical energy, and the output mechanical energy drives the motor to drive the reducer to stir the fermentation tank; the turbine expands After the machine does work, the low-temperature and low-pressure gas is discharged through the valve into the muffler and discharged.

Embodiment 3

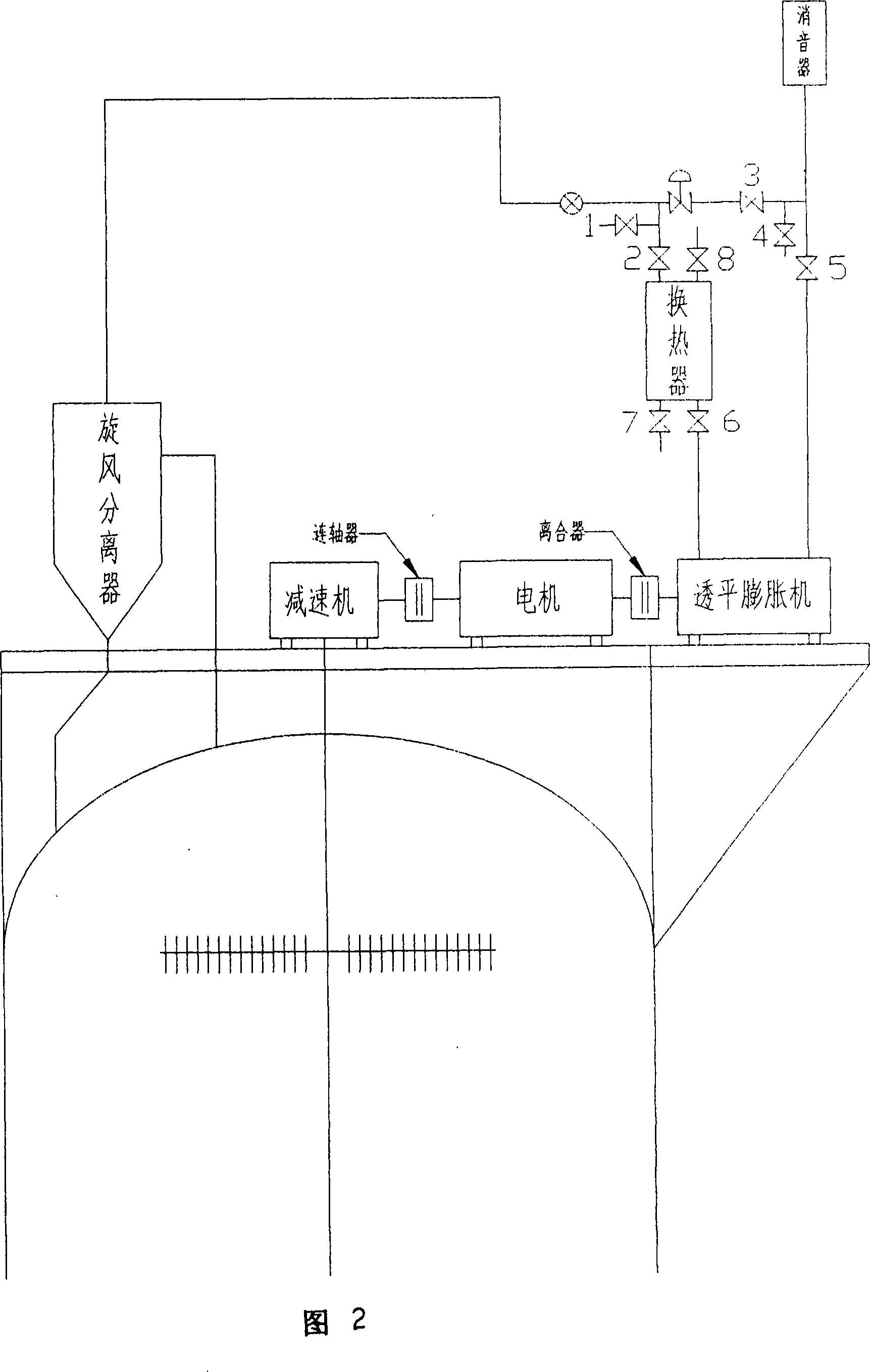

[0022] As shown in Figure 3: Two circuits are connected in parallel on the exhaust pipe of the fermentation tank. One circuit is connected to the heat exchanger and the turbo expander, and the other circuit is connected to the turbo expander at one end and the silencer at the other end. It is connected to the generator through the coupling. The tail gas of the fermentation tank is introduced into the heat exchanger through valve control. After the tail gas is heated in the heat exchanger, it enters the turbo expander to directly perform work, converting heat and pressure energy into mechanical energy, and the output mechanical energy directly drives the generator to generate electricity; the turbo expander does work After that, the low-temperature and low-pressure gas is discharged into the muffler through the valve and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com