Three-dimensional printing photosensitive resin material containing macromelecular elastomers and preparation method

A photosensitive resin and 3D printing technology, applied in the field of 3D printing materials, can solve problems such as poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 3D printing photosensitive resin material containing macromolecular elastomer is composed of the following components by mass percentage: mixed photoinitiator 1%; bornyl methacrylate 8%; N-vinylpyrrolidone 1%; macromolecular elastomer 50%; 1,4-cyclohexyldimethanol divinyl ether 20%; diethoxybisphenol A dipropylene ester 20%.

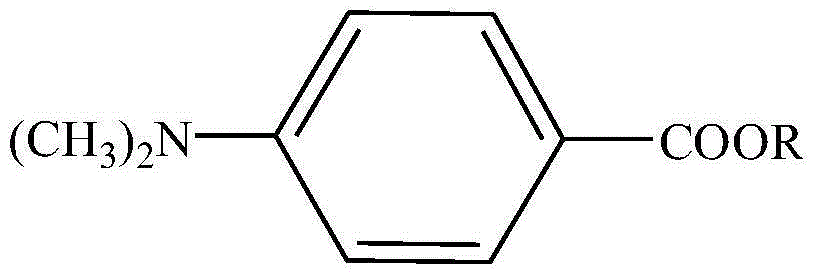

[0032] Wherein, R in the structural formula of tertiary amine benzoate is methyl.

[0033] The above-mentioned 3D printing photosensitive resin material containing macromolecular elastomer, the preparation method is as follows:

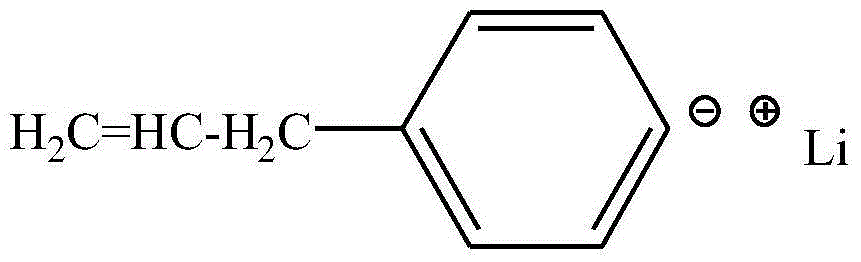

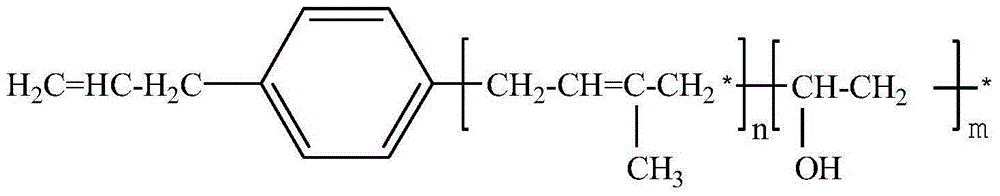

[0034] (1) Preparation of macromolecular elastomer: According to the basic steps of anionic polymerization, using toluene as solvent, adding lithium-containing initiator and isoprene in sequence, reacting at 90-100 °C for 2 h to room temperature, adding ring Ethylene oxide liquid, reacted at 50-70°C for 1 h, the mass ratio of the toluene, lithium-containing initiator, isoprene, and ethylene oxide is (4-8): (0.5-1): 1: ...

Embodiment 2

[0038] A 3D printing photosensitive resin material containing macromolecular elastomer, the composition is as follows: mixed photoinitiator 4%; bornyl methacrylate 18%; N-vinylpyrrolidone 1%; macromolecular elastomer 30%; 1,4 - cyclohexyl dimethanol divinyl ether 22%; diethoxybisphenol A dipropylene ester 25%.

[0039] Wherein, R in the structural formula of tertiary amine benzoate is ethyl.

[0040] The above-mentioned 3D printing photosensitive resin material containing macromolecular elastomer, the preparation method is as follows:

[0041] (1) preparation of macromolecular elastomer: same as Example 1;

[0042] (2) Weigh out 18 g of bornyl methacrylate; 1 g of N-vinyl pyrrolidone; 30 g of macromolecular elastomer; 22 g of 1,4-cyclohexyl dimethanol divinyl ether; diethoxybisphenol A dipropylene ester 25g, mix in a mixer for 1h, the stirring speed is 500r / min, add photoinitiator 1173, 369 and tertiary amine benzoate 0.8g, 0.8g, 2.4g respectively in a dark environment, stir...

Embodiment 3

[0045] A 3D printing photosensitive resin material containing macromolecular elastomer, the composition is as follows: mixed photoinitiator 5%; bornyl methacrylate 13%; N-vinylpyrrolidone 7%; macromolecular elastomer 40%; 1,4 - cyclohexyl dimethanol divinyl ether 10%; diethoxybisphenol A dipropylene ester 25%.

[0046] Wherein, R in the structural formula of tertiary amine benzoate is tert-butyl.

[0047] The above-mentioned 3D printing photosensitive resin material containing macromolecular elastomer, and its preparation method is as follows:

[0048] (1) preparation of macromolecular elastomer: same as Example 1;

[0049](2) Weigh out 13 g of bornyl methacrylate; 7 g of N-vinyl pyrrolidone; 40 g of macromolecular elastomer; 10 g of 1,4-cyclohexyl dimethanol divinyl ether; diethoxybisphenol A dipropylene ester 25g, mix in a mixer for 1h, stirring speed is 500r / min, add photoinitiator 1173, 369 and tertiary amine benzoate 1g, 1g, 3g respectively in a dark environment, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com