A kind of tunnel sealing facility and sealing method thereof

A tunnel and crushed stone technology is applied in the field of blocking flood discharge facilities in non-coal mine tailings ponds, which can solve the problems of polluting the surrounding environment, easily causing harm, polluting the water source, etc., and achieves economical and reasonable construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

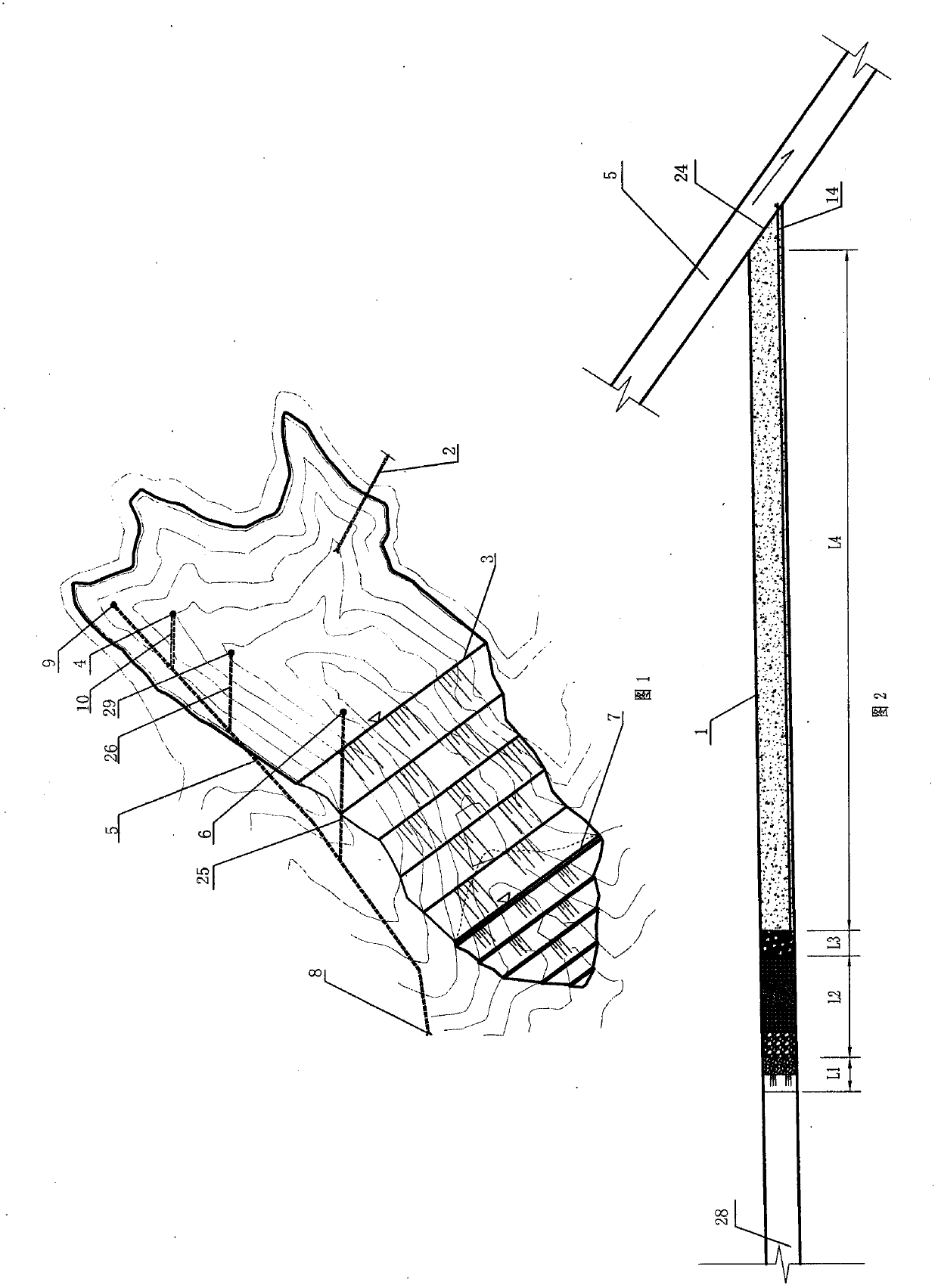

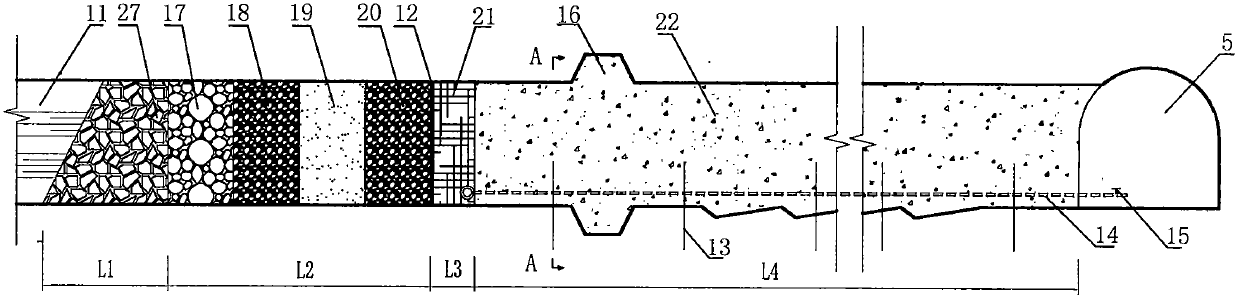

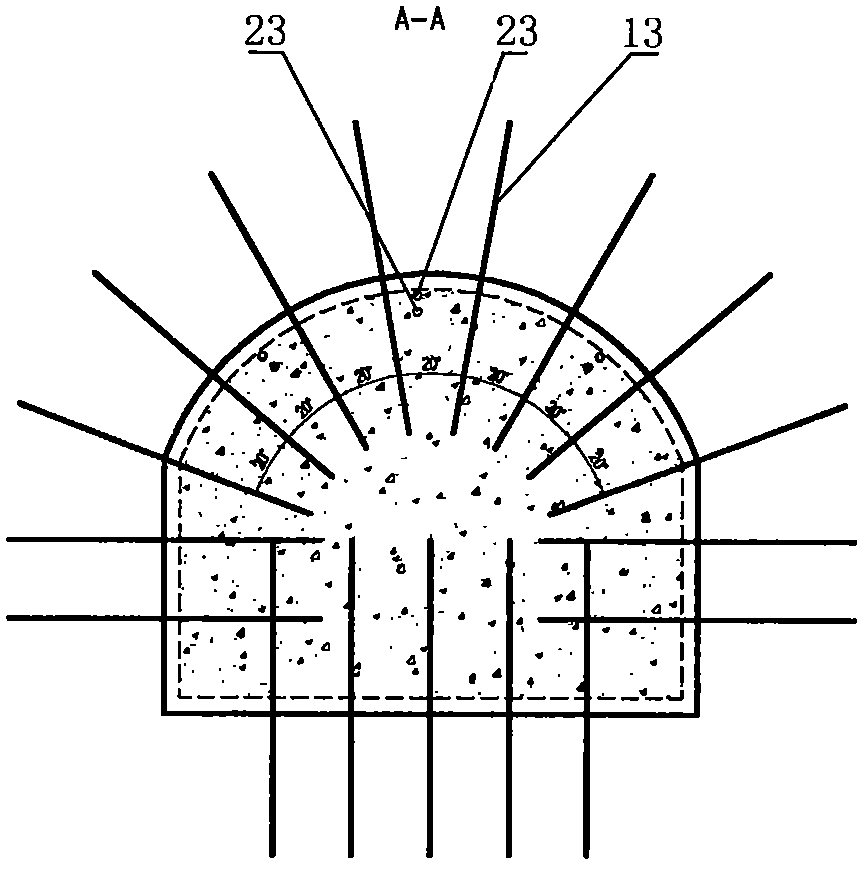

[0033] Such as Figures 2 to 10 As shown, a tunnel sealing facility of the present invention includes a blocking tunnel 1, one end of the blocking tunnel 1 is connected with the drainage tunnel 5, the other end of the blocking tunnel 1 is connected with the tailings pond, and the blocking tunnel 1 is provided with a protective body 27. Filtering body, water collecting body and blocking body 22, protection body 27 is located on the left side of the filtering body, filtering body is located on the left side of the water collecting body, water collecting body is located on the left side of the blocking body 22, and the blocking body 22 is adjacent to the drainage tunnel 5 side, the protective body 36 is adjacent to the side of the tailings pond, the sealing body 22 is provided with a drainage pipe 14, the drainage pipe 14 runs through the sealing body 22, one end of the drainage pipe 14 is connected with the water collection body, and the other end of the drainage pipe 14 It comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com