A kind of process method of full recovery of mixed refrigerant

A process method and technology for mixing refrigerants, applied in the oil and gas industry, can solve the problems of releasing refrigerant, increasing operating costs, slow restarting process, etc., and achieving the effect of reducing pre-cooling time, reducing economic losses, and saving start-up time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

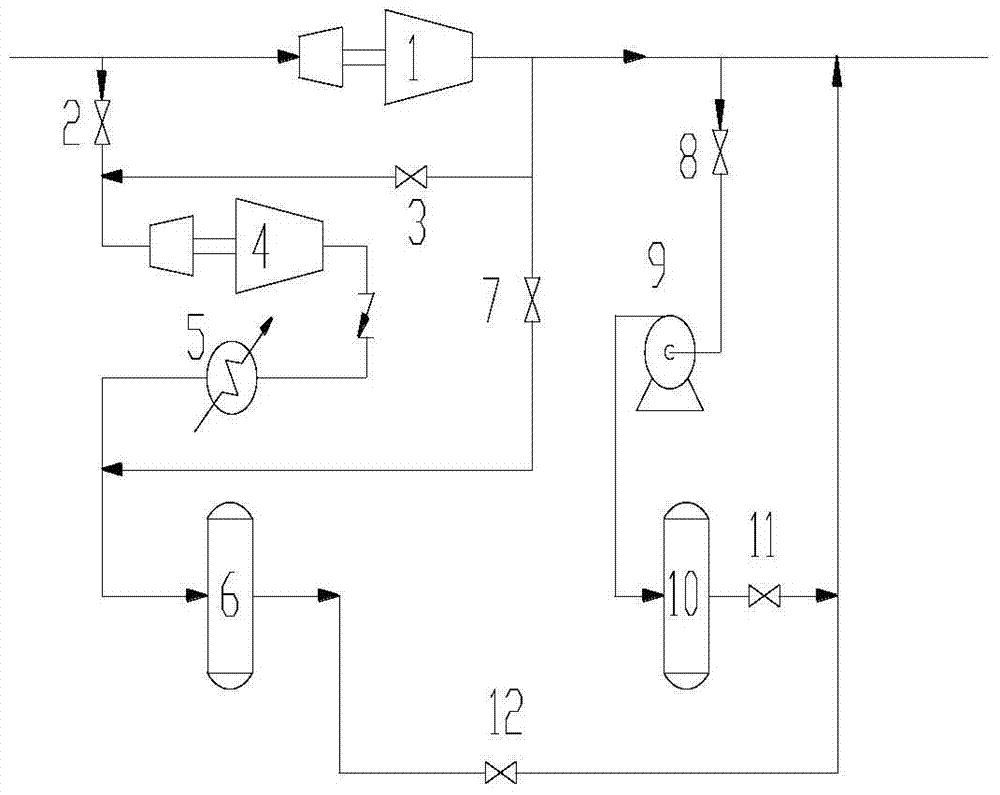

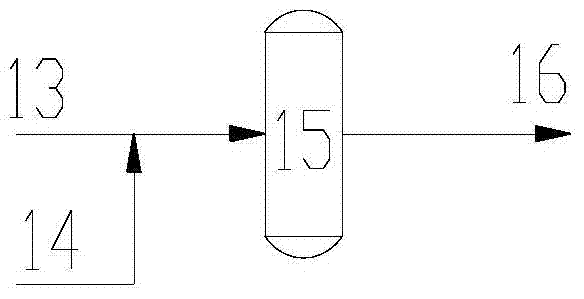

[0031] figure 1 , figure 2 The full flow of this recycling method is shown. When the liquefaction plant system or the equipment of a certain refrigerant circulation system needs to be overhauled, it needs to be shut down for operation. However, handling of the mixed refrigerant after shutdown is a key issue. The previous practice was to short directly, which caused a lot of economic losses. Based on this, there is a research on this method. The method separates the hot and cold refrigerants into two systems and recovers them separately, meeting the requirement of full recovery of the refrigerants.

[0032] (1) When the machine is shut down for maintenance, the compressor 1 of the refrigerant circulation system stops running. At the inlet of compressor 1, it is a hot and low-pressure refrigerant, where the refrigerant is in a complete gas state, and needs to be pressurized by a small refrigerant compressor 4 to the same pressure as the outlet of compressor 1 of the circula...

Embodiment 1

[0039] After the compressor 1 of the refrigerant circulation system stops running, the hot high-pressure valve 8 is first opened, and the hot high-pressure liquid-phase refrigerant is recovered according to the process described in (3) above. Then judge the pressure of the hot high-pressure gas-phase refrigerant and the pressure in the hot-low pressure refrigerant recovery tank 6. If the pressure of the gas-phase refrigerant is small, it needs to go through the pressure reducing valve 3 to reduce the pressure, and then go through the small compressor 4 to increase the pressure. pressure, then enter the hot and low pressure refrigerant recovery tank 6 for storage. If the gas-phase pressure is sufficient to enter the hot and low-pressure refrigerant recovery tank 6 , the bypass valve 7 is opened, and the gas-phase refrigerant directly enters the hot and low-pressure refrigerant recovery tank 6 .

[0040] After the recovery of the hot high-pressure refrigerant is completed, at th...

Embodiment 2

[0045] After the compressor 1 of the refrigerant circulation system stops running, the hot high-pressure valve 8 is first opened, and the hot high-pressure liquid-phase refrigerant is recovered according to the process described in (3) above. Then judge the pressure of the hot high-pressure gas phase refrigerant and the pressure in the hot low pressure refrigerant recovery tank 6, if the gas phase pressure is enough to enter the hot low pressure refrigerant recovery tank 6, then open the bypass valve 7, and the gas phase refrigerant directly enters the hot low pressure refrigerant recovery tank 6. Agent recovery tank 6.

[0046] After the recovery of the hot high-pressure refrigerant is completed, at this time, the pressure of the entire refrigerant circulation system drops. Close the hot high-pressure valve 8, open the hot low-pressure valve 2, and recover the hot and low-pressure refrigerant according to the process described in (1).

[0047] At the same time, the low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com