Method and device used for controlling and researching bubble polymerization process

A technology of bubbles and electrolyte, which is applied in the field of controlling and studying the bubble polymerization process. It can solve the problems of fast bubble movement, high camera requirements, and difficult observation, and achieve the effects of long duration, low requirements, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

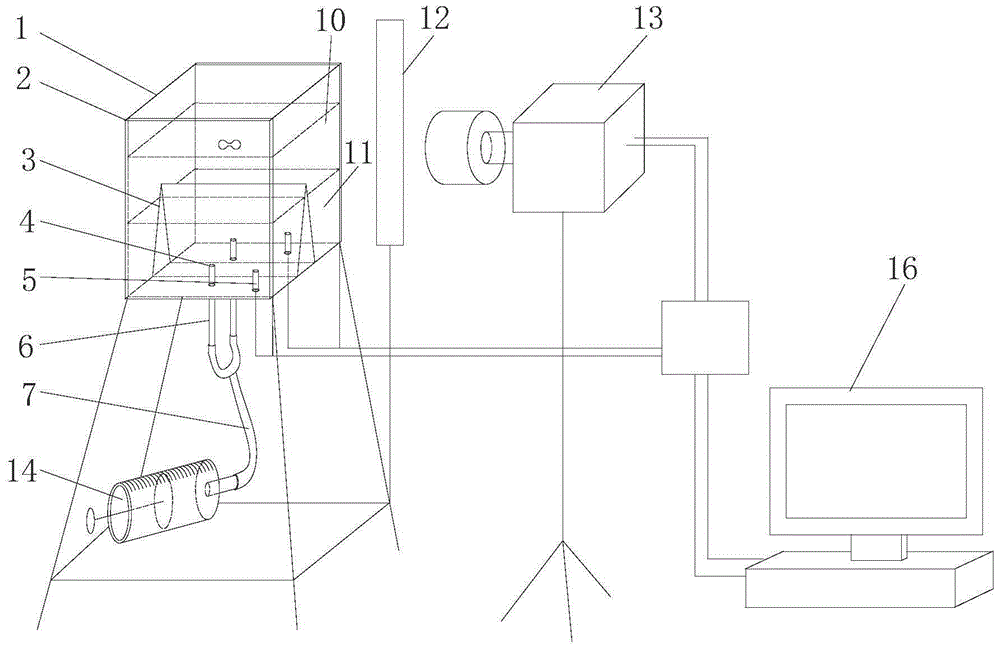

[0020] Such as figure 1 The device shown in the method for controlling and studying the bubble polymerization process includes an electrolyte storage tank 1, a dielectric separator 3 installed on the bottom of the cavity of the electrolyte storage tank 1 and separating it into two chambers, and symmetrically installed on the electrolytic tank 1. The two metal electrode plates 2 forming an electric field on the outside of the liquid storage tank 1, the microporous tube 4 and the electrode 5 in the small hole on the electrolyte storage tank 1 at the bottom of each chamber are arranged in the electrolyte storage tank 1 The bubble observation and analysis equipment on the front side, the electrodes 5 in the two chambers have opposite polarities, which are posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com