A Multivariate Industrial Process Fault Identification Method

A technology for industrial process and fault identification, which is applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc. It can solve the problems of noise information deteriorating the identification effect and inability to make full use of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

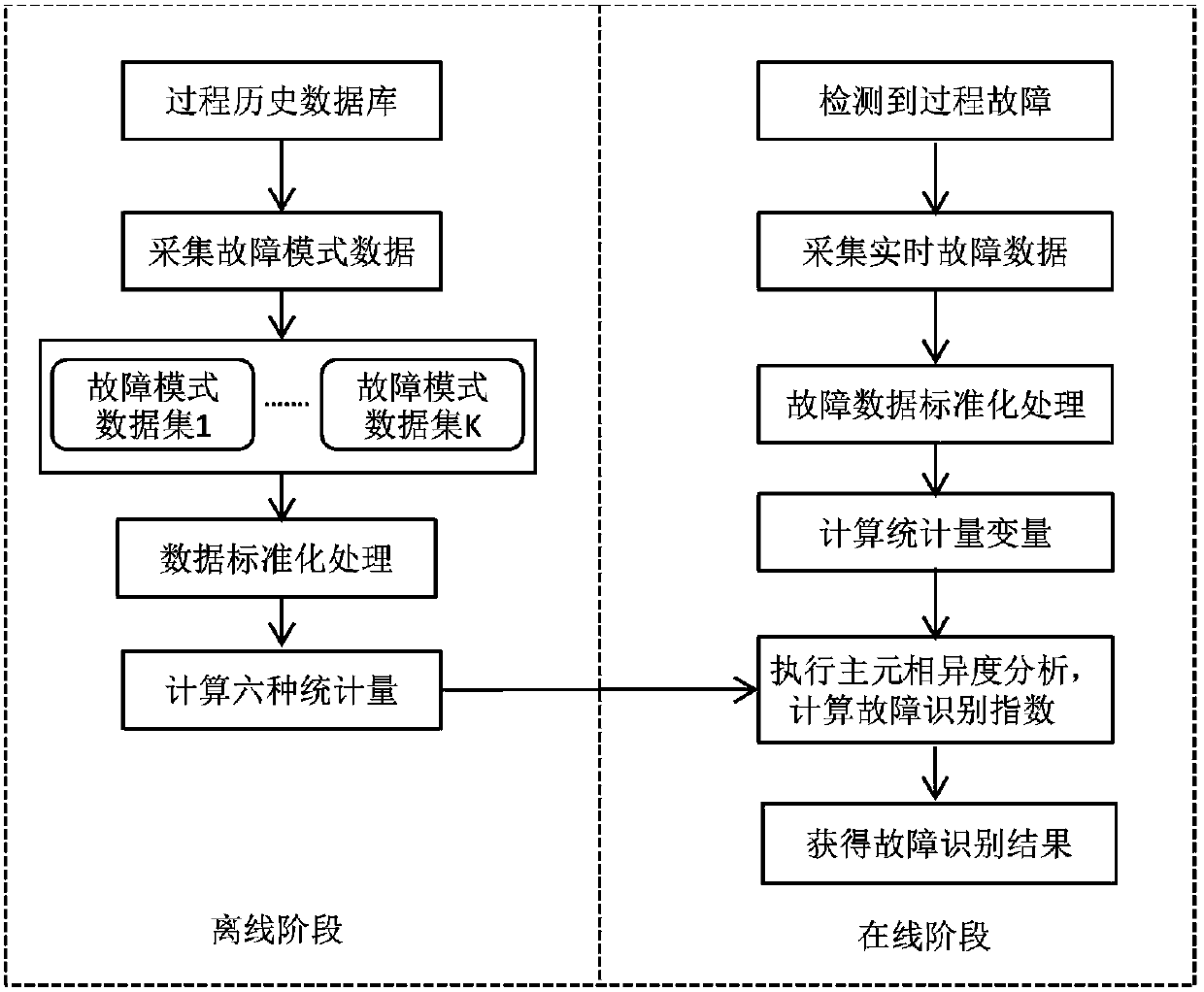

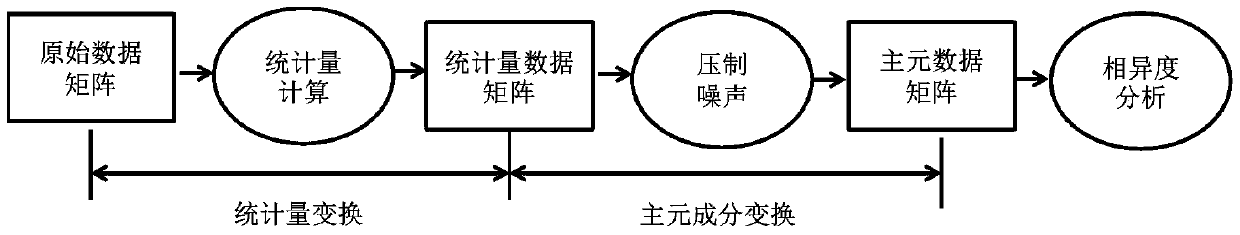

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Take the CSTR system as an example. The CSTR system is a chemical reactor. The solution of material A enters the reactor, and a first-order irreversible chemical reaction occurs to generate material B. The reaction is an exothermic reaction, so it needs to pass through the external clamp. The cooling agent takes away the heat of reaction. In order to ensure the normal operation of the process, it generally has a cascade control system.

[0079] According to the process mechanism, the dynamic mechanism model of the CSTR system is established as follows:

[0080] dc A d t = - k 0 e - E / R T + Q F c...

Embodiment 2

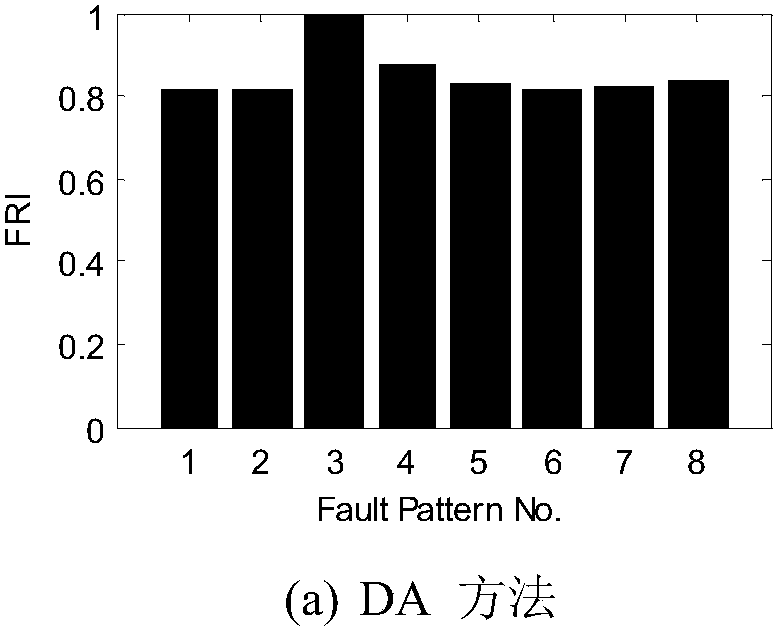

[0177] Embodiment 2: Taking a well-known TE chemical process as an example, the TE chemical process has been widely used in fault diagnosis and process control method research. The TE chemical process consists of five units, with a total of 52 process variables, including 11 operating variables, 19 component variables and 22 continuous measurement variables. The flow chart of the TE chemical process is as follows Image 6 shown. Additional details on TE chemical processes are found in references (J.J. Downs, E.F. Vogel, Aplant-wide industrial process control problem, Computers & Chemical Engineering, 17 (1993) 245-255).

[0178] The simulation data package of TE chemical process can be downloaded from the website http: / / web.mit.edu / braatzgroup / index.html. The data packet contains 1 normal working condition and 21 fault working condition data IDV(1)~IDV(21). The normal working condition data has 500 sampling points and 52 variables. The fault data set is divided into two cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com