Integrative data source based automatic optimization scheduling system and method for steel, iron and energy source

A scheduling system and comprehensive data technology, applied in the energy industry, sustainable manufacturing/processing, comprehensive factory control, etc., can solve problems such as poor scheduling effect, overloaded scheduling personnel, complex scheduling problem combinations, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

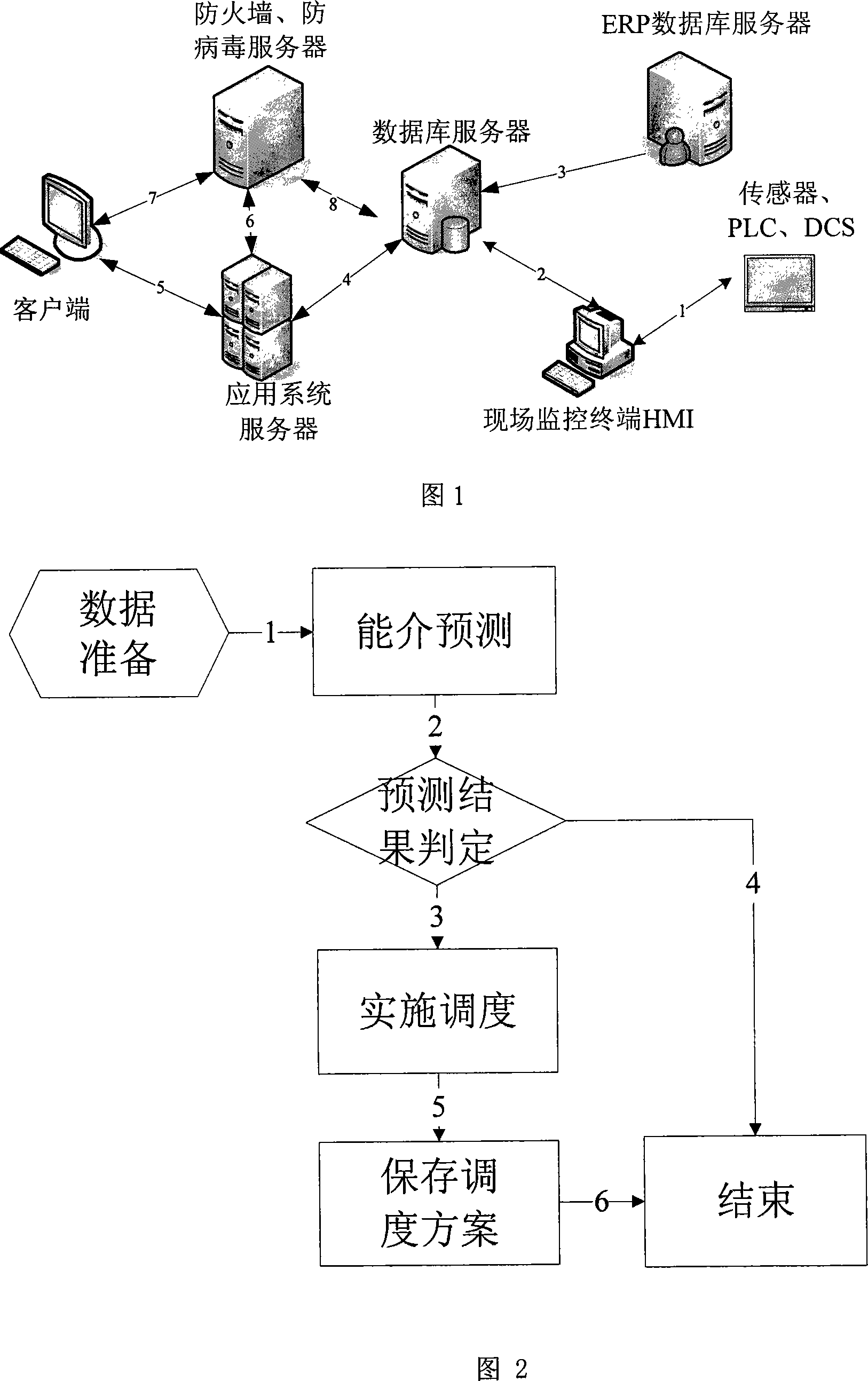

[0063] 1) According to the network equipment required by the energy dispatching system (as shown in Figure 1), carry out the necessary network steps, and combine the on-site sensors, PLC, and DCS to form the PCS layer; on-site monitoring terminal HMI; dispatching system database server; ERP Database server; application system server; client; firewall, anti-virus server and other hardware devices are friendly connected to form the required computer network hardware structure;

[0064] 2) Implement the necessary deployment to the dispatch system database server to enable it to automatically collect the PCS layer related energy detection index data collected by the field monitoring terminal HMI in the background;

[0065] 3) For the data obtained from the ERP database server, do the necessary data conversion, select the appropriate form to store, and prepare the basic data for the implementation of energy scheduling;

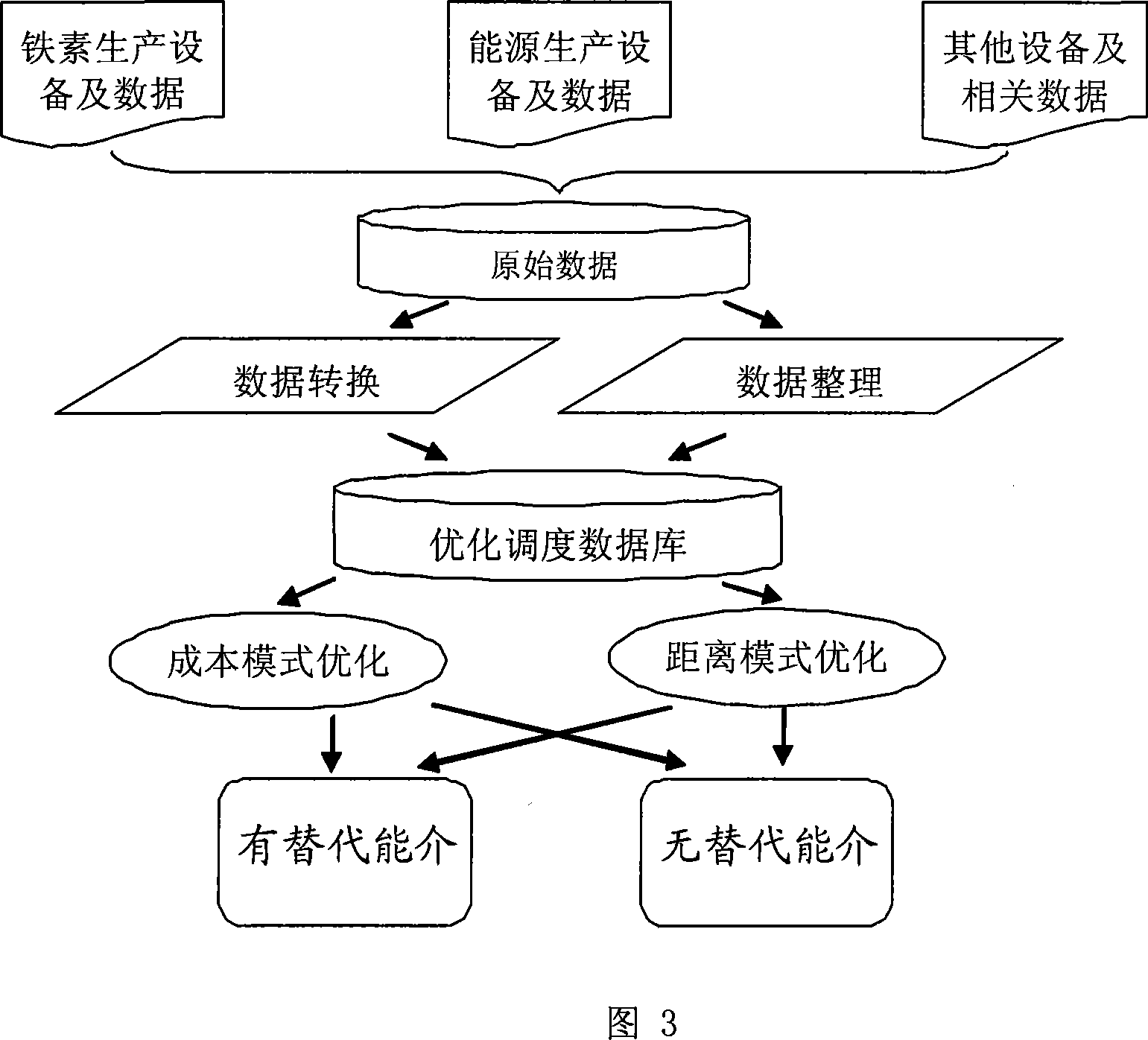

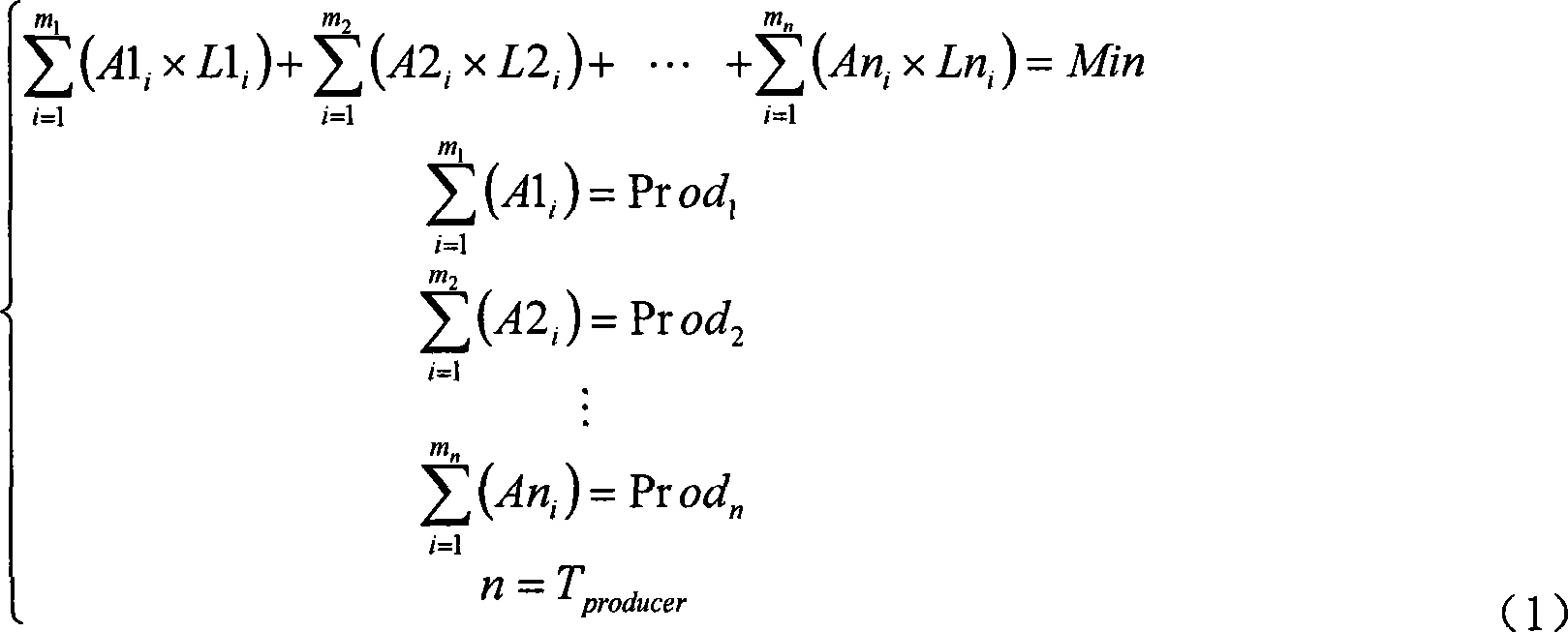

[0066] 4) For some basic data required for energy forecasting and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com