Organic electroluminescent device, manufacturing method thereof and display device

An electroluminescent device and electroluminescent technology, applied in the manufacturing of organic semiconductor devices, electro-solid devices, semiconductor/solid-state devices, etc., can solve the problems of reducing luminous efficiency, not effectively improving, affecting OLED performance, etc. Effect of Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

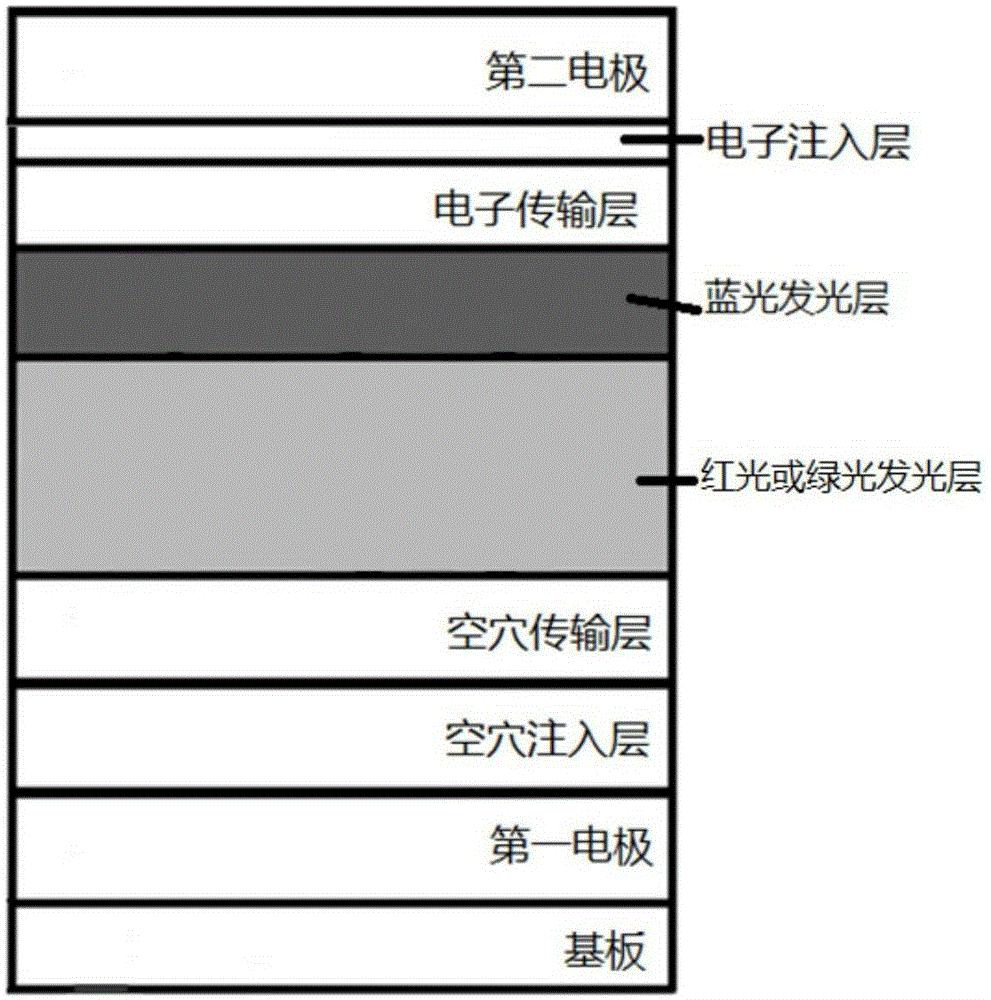

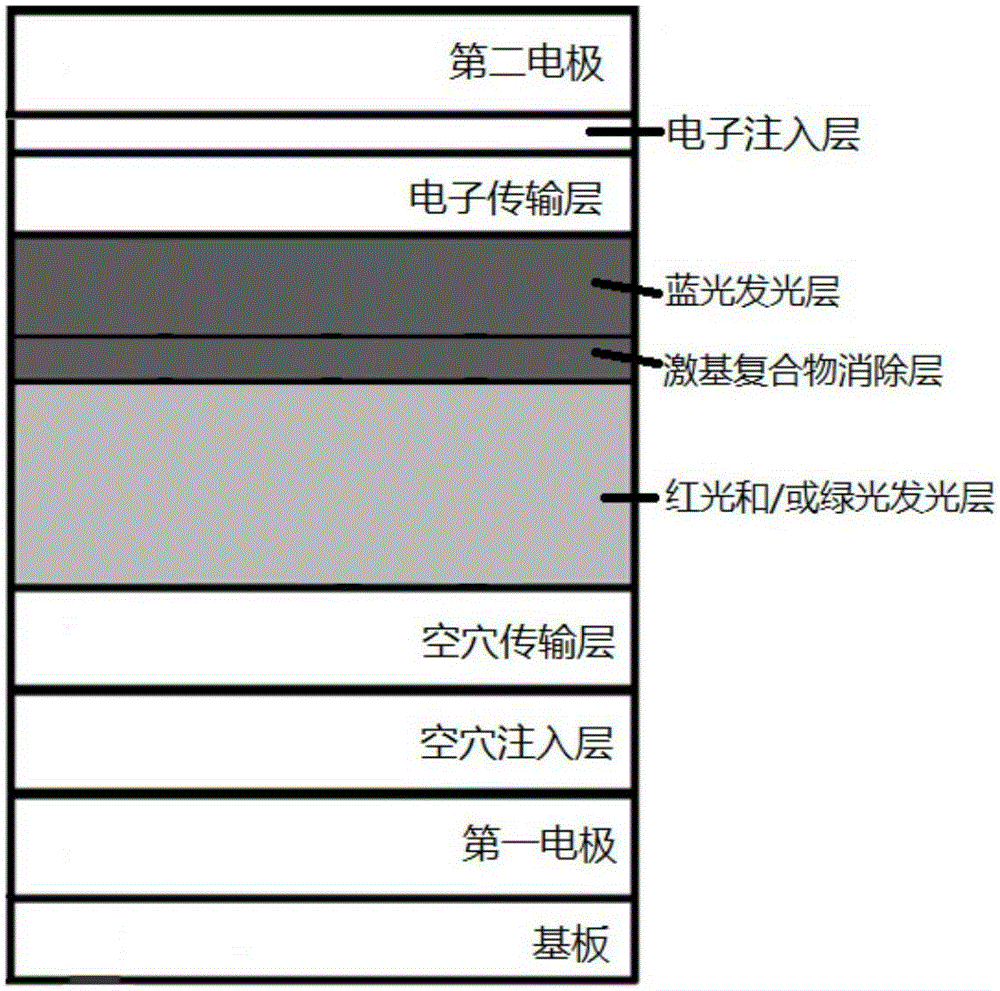

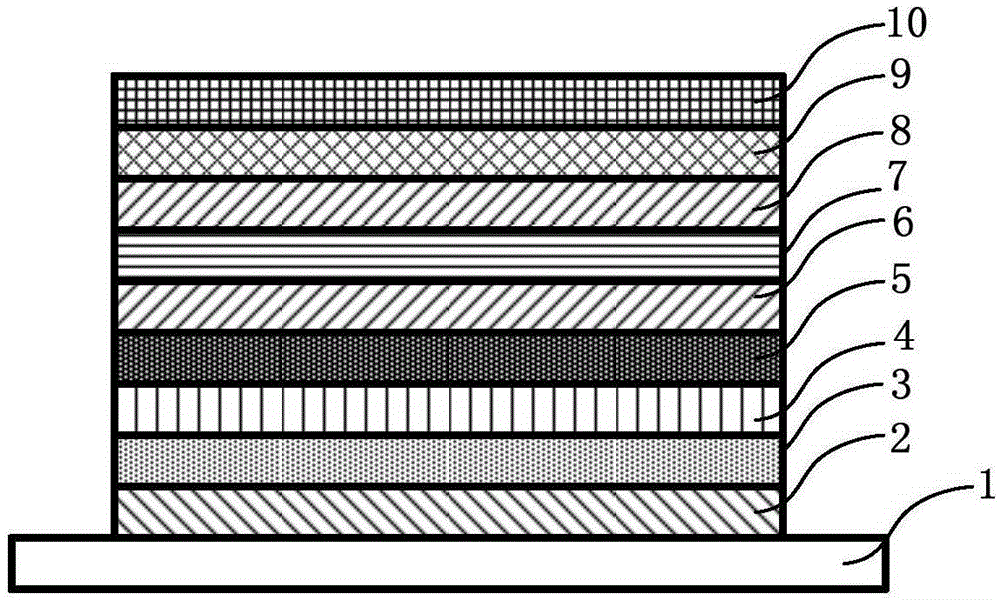

[0059] In order to more clearly illustrate the technical solution of the present invention, the following combination image 3 The cross-sectional schematic diagram of the structure of the organic electroluminescent device shown in the illustrated embodiment 1, as Figure 4 As shown, the manufacturing method of this embodiment may specifically include the following steps:

[0060] S1: forming an indium tin oxide (Indium Tin Oxides, ITO) layer on the substrate 1, and etching the ITO layer to form the first electrode 2;

[0061] Wherein, the substrate 1 is transparent glass, and the thickness of the first electrode 2 is about 70 nm. It should be noted that after the first electrode 2 is formed, the ITO glass substrate is cleaned in an ultrasonic environment of deionized water, acetone and absolute ethanol, and then dried with nitrogen N2 and treated with oxygen plasma.

[0062] S2: The hole injection layer 3, the hole transport layer 4 and the green light emitting layer 5 are sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com