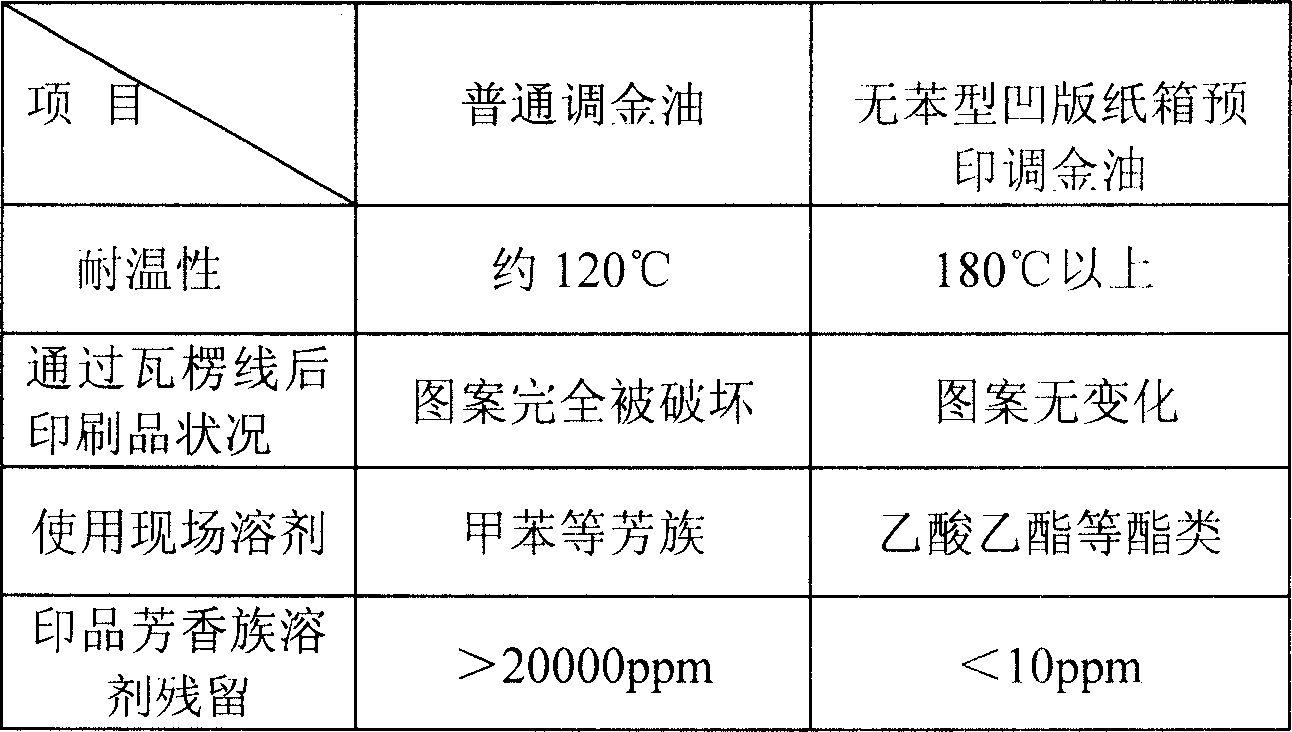

No-benzene pre-printing metal regulating oil for concave paper box

A technology of gold-adjusting oil and carton, applied in ink, household utensils, applications, etc., can solve problems such as inability to use gold ink, and achieve the effects of consistent color, excellent gloss, and superior metal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, benzene-free gravure carton pre-print gold-adjusting oil, is made of the following components, and the dosage is mass percent:

[0022] Thermoplastic methyl methacrylate resin 38%

[0023] Propylene Glycol Methyl Ether Acetate 8%

[0024] Dioctyl phthalate 2%

[0025] Butyl acetate 52%

[0026] After mixing the above-mentioned prepared raw materials, pour them into the mixer and heat while stirring. The heating temperature is 51-57°C until it is fully dissolved.

Embodiment 2

[0027] Embodiment 2, benzene-free gravure carton pre-printed gold-adjusting oil, is made of the following components, and the dosage is mass percent:

[0028] Thermoplastic Acrylic 28%

[0029] Propylene Glycol Methyl Ether Acetate 4%

[0030] Dioctyl phthalate 4%

[0031] n-Propyl Acetate 64%

[0032] After mixing the above-mentioned prepared raw materials, pour them into a mixer and heat while stirring. The heating temperature is 52-58°C until it is fully dissolved.

Embodiment 3

[0033] Embodiment 3, benzene-free gravure carton pre-print gold-adjusting oil, is made of the following components, and the dosage is mass percent:

[0034] Ethylene / vinyl acetate copolymer resin 45%

[0035] Propylene glycol methyl ether acetate 6%

[0036] Dioctyl phthalate 8%

[0037] Isopropyl acetate 41%

[0038] After mixing the above-mentioned prepared raw materials, pour them into a mixer and heat while stirring. The heating temperature is 53-59°C until it is fully dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com