Multi-main-grid battery piece assembly and preparation process thereof

A preparation process and cell technology, applied in electrical components, sustainable manufacturing/processing, circuits, etc., can solve the problems of lower utilization of sunlight by photovoltaic cells, hindering cells from absorbing sunlight, and reducing photoelectric conversion efficiency, etc. Achieve the effect of avoiding light loss, improving mechanical properties and flame retardant properties, and promoting compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 60 groups of cells with the same color and the same efficiency and divide them into one group, and perform scribing on a dicing machine to make a multi-busbar half cell. The cell is a multi-busbar cell, and the cell assembly is a polycrystalline 12-bar components;

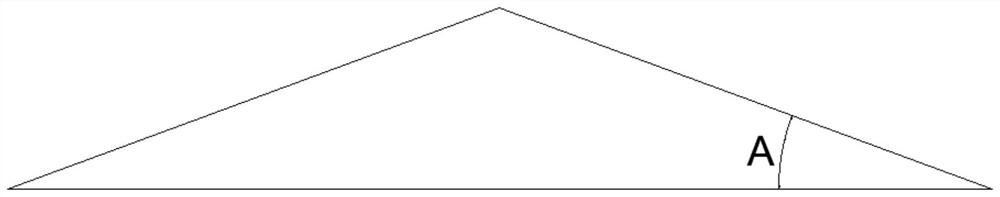

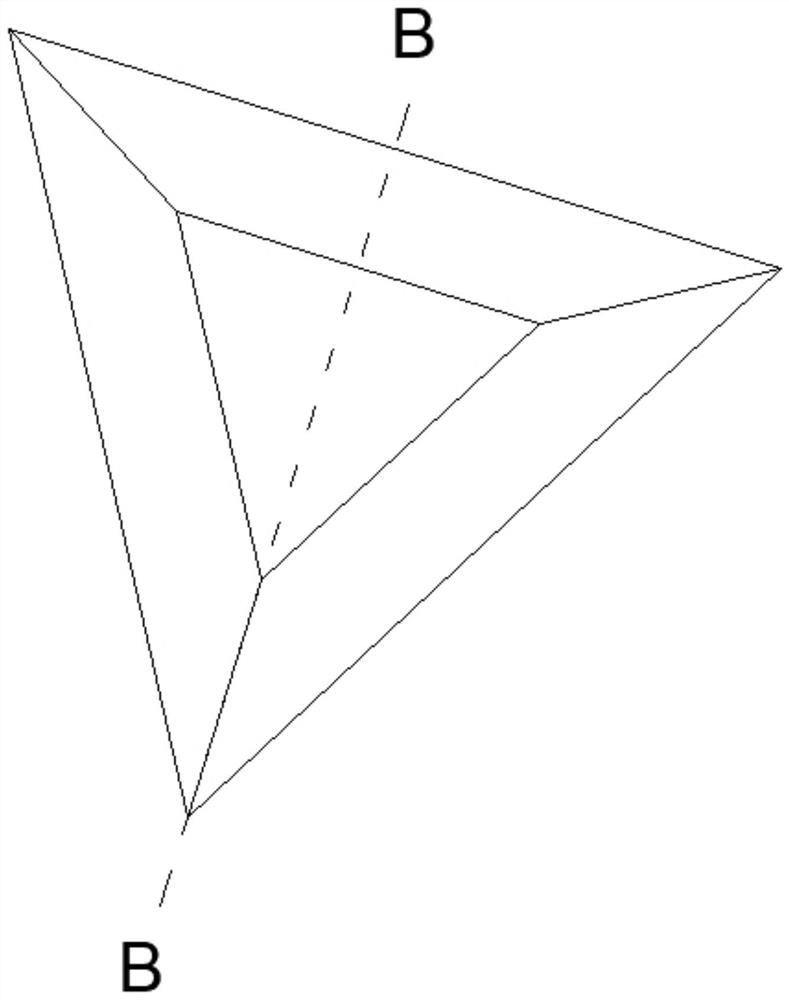

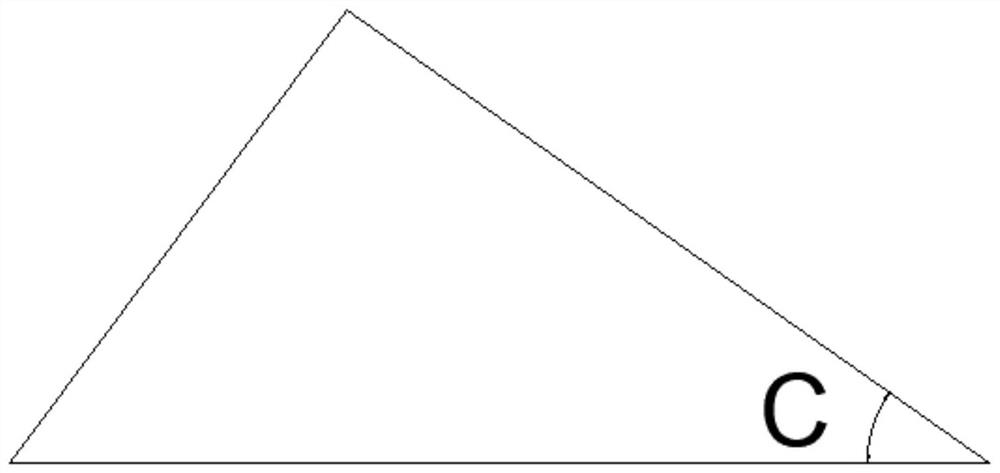

[0039] Take an oxygen-free copper strip and press it to make a copper base, then place it in a tin alloy in a molten state for 10 seconds to form a coating, take it out and attach it to an aluminum strip, and emboss it at a temperature of 150°C to form an embossed structure , to obtain a solder strip, wherein the tin alloy includes the following components by weight: 60 parts of tin, 36.5 parts of lead, 3.0 parts of silver, 0.5 part of copper, the oblique angle A of the copper-based cross-sectional triangle is 5.4°, and the triangular edge in the embossed structure The angle C between the hypotenuse of the platform and the coating is 30.5°;

[0040] Take polyphenylene ether and dissolve it in 1,2-dichl...

Embodiment 2

[0044] Take 60 groups of cells with the same color and the same efficiency and divide them into one group, and perform scribing on a dicing machine to make a multi-busbar half cell. The cell is a multi-busbar cell, and the cell assembly is a polycrystalline 12-bar components;

[0045] Take an oxygen-free copper strip and press it to obtain a copper base, then place it in a molten tin alloy for 35 seconds to form a coating, take it out and attach it to an aluminum strip, and emboss it at a temperature of 160°C to form an embossed structure , to obtain a solder strip, wherein the tin alloy includes the following weight components: 78 parts of tin, 18 parts of lead, 1.5 parts of silver, 0.2 part of copper, the oblique angle A of the copper-based cross-sectional triangle is 13.5°, and the triangular edges in the embossed structure The angle C between the hypotenuse of the platform and the coating is 36°;

[0046] Take polyphenylene ether and dissolve it in 1,2-dichloroethane, add...

Embodiment 3

[0050] Take 60 groups of cells with the same color and the same efficiency and divide them into one group, and perform scribing on a dicing machine to make a multi-busbar half cell. The cell is a multi-busbar cell, and the cell assembly is a polycrystalline 12-bar components;

[0051] Take an oxygen-free copper strip and press it to make a copper base, then place it in a molten tin alloy for 60 seconds to form a coating, take it out and attach it to an aluminum strip, and emboss it at a temperature of 170°C to form an embossed structure , to make a solder strip, wherein the tin alloy includes the following weight components: 96 parts of tin, 3.0 parts of silver, 0.5 part of copper, the oblique angle A of the copper-based cross-sectional triangle is 21.5°, and the hypotenuse of the triangular truss in the embossed structure The angle C with the coating is 41.6°;

[0052] Take polyphenylene ether and dissolve it in 1,2-dichloroethane, add 4-fluorobenzoyl chloride, anhydrous alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com