Wellbore drilling system

A drilling and wellbore technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

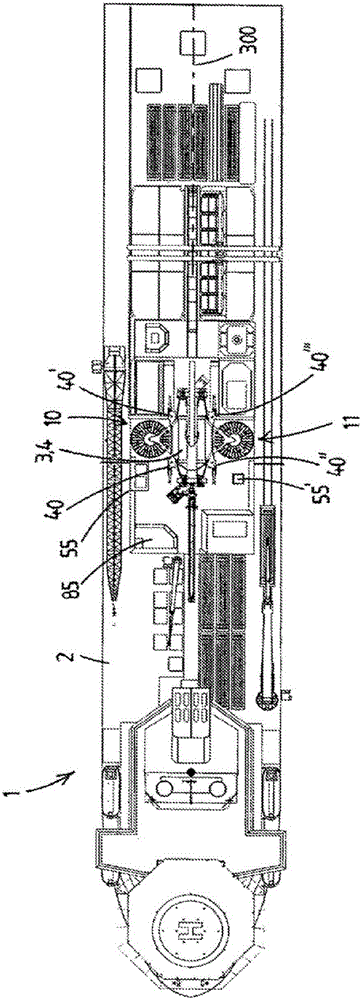

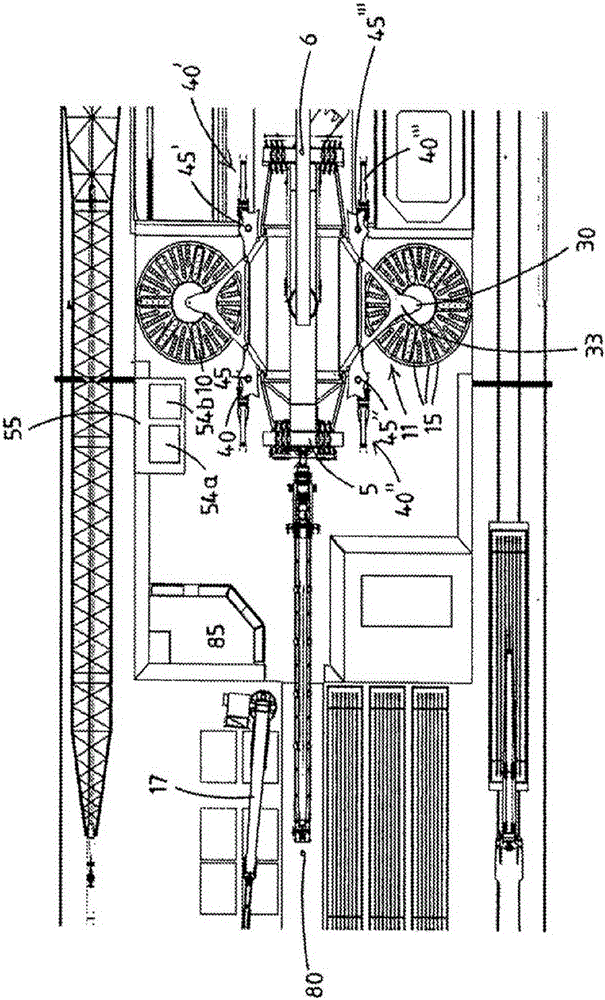

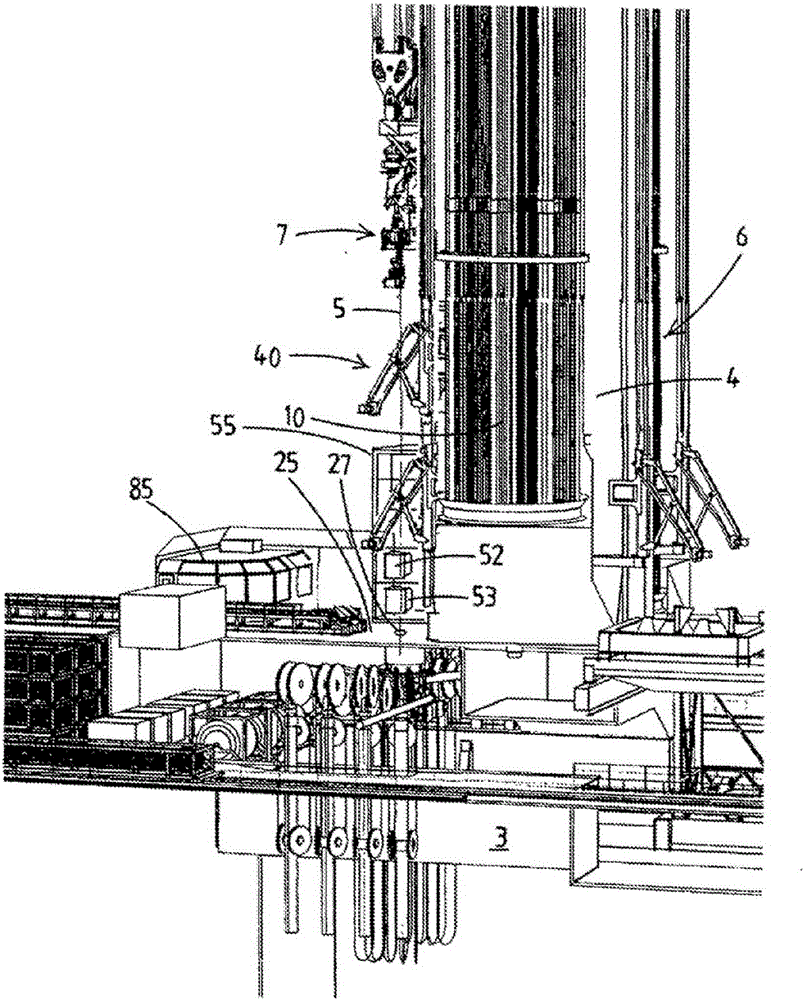

[0147] will now refer to Figure 1 to Figure 5 An embodiment of an oil and gas offshore drilling vessel equipped with a wellbore drilling system according to the present invention will be described.

[0148]Here, the ship 1 is a monohull with a hull 2 through which a well 3 extends. A drilling tower (here the drill rig 4 ) is mounted on the hull, in this case above the boat well 3 . The drill frame is associated with a lifting device (known in the art as a drilling winch) which in the embodiment shown runs along the outside of the drill frame (here the side of the drill frame 4) extending through the shipwell 3 front and rear) and form two working lines 5,6 thereon.

[0149] A drill floor 25 is provided which has a drilling center 27 through which a drill string passes along a working line (here working line 5 ).

[0150] The line 5 is designed to perform drilling and here comprises a drill string rotary drive (here a top drive 7 or other rotary drive) adapted to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com