Water-absorbent non-woven fabric and preparation method thereof as well as medical non-woven fabric

A technology of non-woven fabrics and spunbonded non-woven fabrics, which is applied in the field of medical non-woven fabrics, can solve the problems of weakened interaction force, loss of tensile ductility, easy to break when stretched, etc., and achieves strong water-locking ability and excellent water-absorbing performance , the effect of good tension elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of water-absorbing non-woven fabric and preparation method thereof

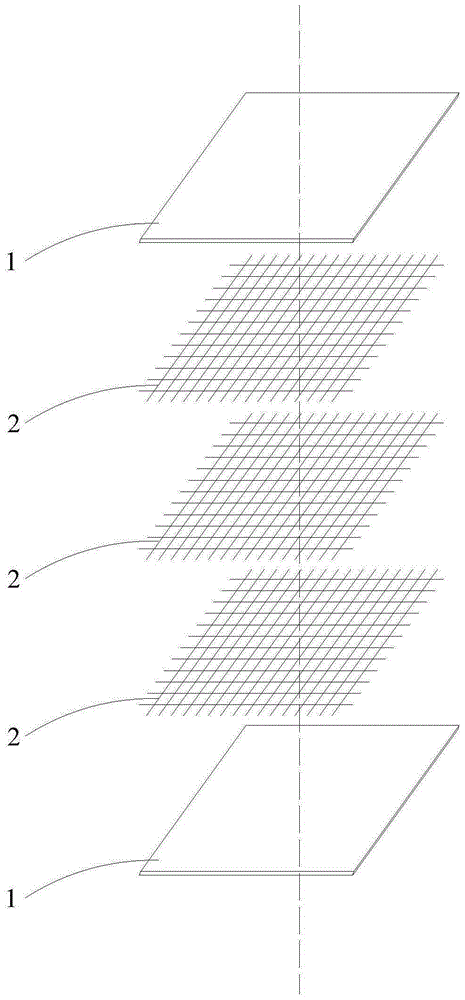

[0022] like figure 1 As shown, the water-absorbing non-woven fabric of this embodiment 1 is formed by bonding the water-absorbing layer 2 and the spun-bonded non-woven fabrics 1 on both sides of the water-absorbing layer 2, and the water-absorbing layer 2 is composed of three layers of polymer water-absorbing resin fiber layers Composition, each layer of polymer water-absorbent resin fiber layer is composed of transverse fiber filaments and longitudinal fiber filaments made of polymer water-absorbent resin. The three layers of polymer water-absorbent resin fiber layers are fixedly connected by acupuncture Together.

[0023] The preparation method of the water-absorbent non-woven fabric in this embodiment 1, the polymer water-absorbent resin is made into polymer water-absorbent resin fiber filaments, and the polymer water-absorbent resin fiber filaments are spun into a criss-cross ...

Embodiment 2

[0024] Embodiment 2: A kind of medical non-woven fabric

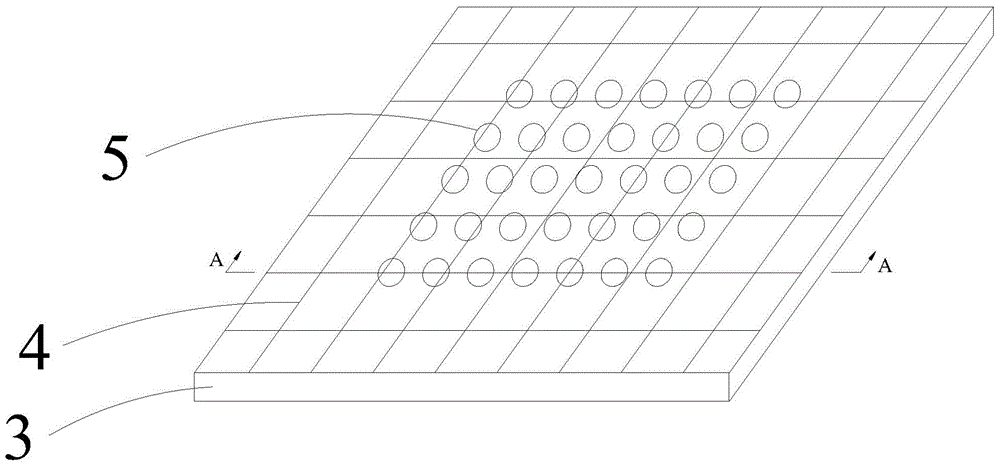

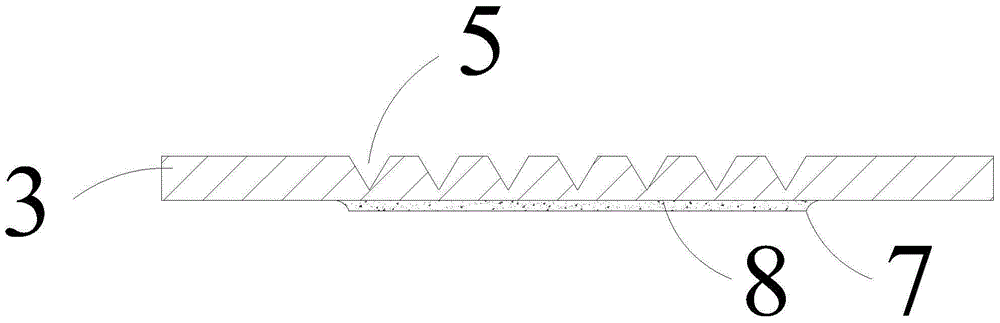

[0025] like Figure 1 to Figure 4 As shown, the medical nonwoven fabric in Example 2 is composed of the water-absorbent nonwoven fabric 3 in Example 1. A plurality of tapered hole grooves 5 are evenly arranged in the middle area of one side of the water-absorbent nonwoven fabric 3 , and the bottom surface ends of the tapered hole grooves 5 are located at the side surface of the water-absorbent nonwoven fabric 3 . The diameter of the bottom surface of the tapered hole groove 5 is 1 mm, and the center-to-center distance between the bottom surfaces of two adjacent tapered hole grooves 5 is 1.5 mm. The water-absorbing non-woven fabric 3 is also bonded with a polyethylene grid thin layer 4 on the side where the tapered hole groove 5 is provided.

[0026]The medical non-woven fabric of this embodiment 2 also includes a TDP element powder layer 8 and a powder-sealing non-woven fabric 7 covering the TDP element powder layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com