Volatile organic waste gas biological treatment system

A volatile organic and biological treatment technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high investment cost, high energy consumption, and high operating cost of waste gas treatment methods, and achieve high practical value , good safety performance and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification.

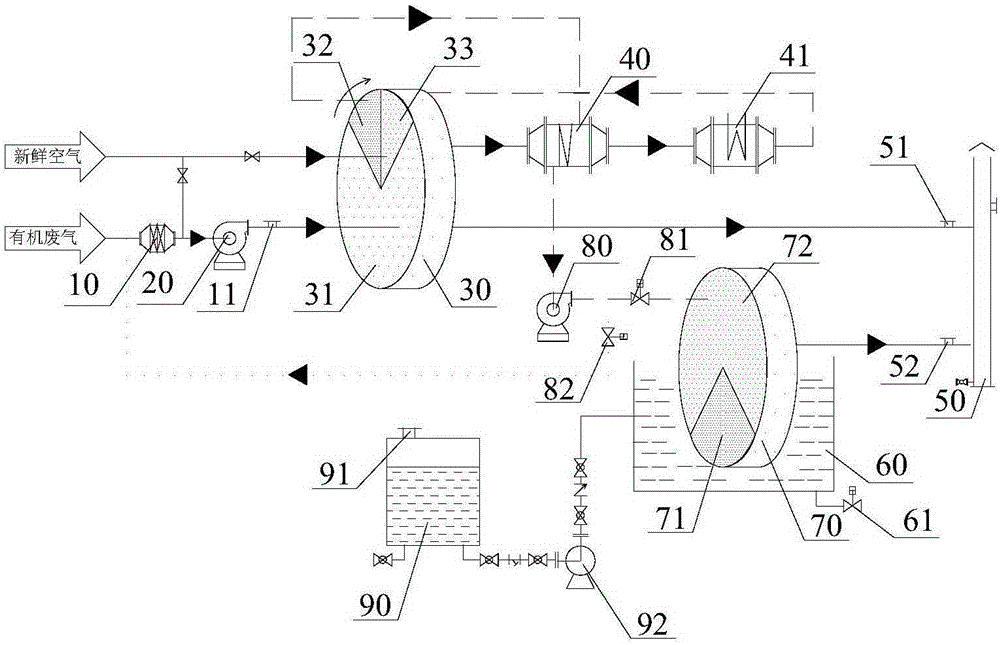

[0023] Such as figure 1 As shown, the present invention provides a biological treatment system for volatile organic waste gas, including an adsorption concentration device, a biodegradation device and a PLC control unit. The organic waste gas is controlled by the PLC control unit through the adsorption concentration device and the biodegradation device to achieve Treatment of organic waste gas.

[0024] The adsorption and concentration device includes a molecular sieve runner 30. The circumferential direction of the molecular sieve runner 30 is sequentially provided with an adsorption zone 31, a regeneration zone 32 and a cooling zone 33 that rotate in sequence, and the temperature of the regeneration zone 32 is controlled between 100 and 120 degrees. The adsorption zone 31, the regeneration zone 32 and the cooling zone 33 are respectively isolated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com