Method for conducting oriented solidification on CET refining metal solidification organization under longitudinal magnetic field

A technology of directional solidification and longitudinal magnetic field, which is applied in the field of metal material remelting and casting processing, can solve the problems of affecting the scope of refinement, melt splashing, splashing, etc., to avoid chilling effect or pollution, prevent liquid splashing, and ensure safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

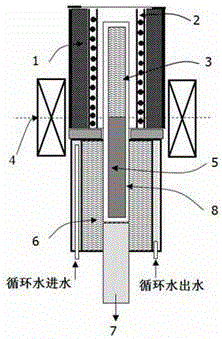

[0026] In this example, see Figure 1 ~ Figure 3 The metal melting and casting device adopted by the directional solidification method of the present invention is composed of a water-cooled jacket 1, a heating furnace 2, a magnet 4, a cooling pool 6, a pull rod 7 and a directional solidification crucible 8, and the directional solidification crucible 8 is heated by the heating furnace 2 to make the metal material melting, the directional solidification crucible 8 is connected to the pull rod 7 of the directional solidification device to form a drawing system, so that it can be pulled in the heating furnace 2 for linear movement, and the pulling of the pull rod 7 and the cooling effect of the cooling pool 6 make the The molten metal material is directional solidified, the upper part in the directional solidification crucible 8 cavity is the alloy rod liquid phase part 3, the lower part in the directional solidification crucible 8 cavity is the alloy rod solid phase part 6, and t...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

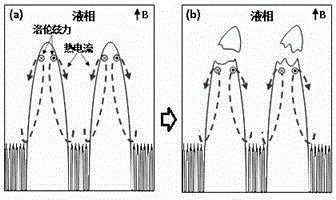

[0034] In this example, see Figure 4 , the present embodiment is a method for directional solidification CET to refine metal solidification structure under longitudinal magnetic field, the steps are as follows:

[0035] a. This step is identical with embodiment one;

[0036] b. Metal melting and casting process: corundum tube is used as the directional solidification crucible 8, the inner diameter of the corundum tube is 3mm, the length is 200mm, the magnet 4 is an electromagnet, and the Al-20wt%Cu alloy rod sample is used, the diameter of the alloy rod sample is 2.9mm, and the length is 150mm , and encapsulate it in a corundum tube for later use, put the vertical directional solidification device into a vertical strong magnetic field, which is generated by a magnet 4, connect the corundum tube to the pull rod 7 of the directional solidification device, so that it can Pulling in the heatin...

Embodiment 3

[0039] This embodiment is basically the same as the previous embodiment, and the special features are:

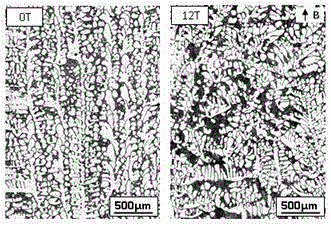

[0040] In this example, see Figure 5 , the present embodiment is a method for directional solidification CET to refine metal solidification structure under longitudinal magnetic field, the steps are as follows:

[0041] a. This step is identical with embodiment one;

[0042] b. Metal melting and casting process: use a corundum tube as the directional solidification crucible 8, the inner diameter of the corundum tube is 3mm, the length is 200mm, the magnet 4 is an electromagnet, and the Al-7wt%Si-1wt%Fe alloy rod sample is used, and the diameter of the alloy rod sample is 2.9 mm, length 150mm, and it is packaged in the corundum tube for standby, the vertical directional solidification device is put into the longitudinal strong magnetic field, and the longitudinal strong magnetic field is produced by the magnet 4, the corundum tube is connected to the pull rod 7 of the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com