Mulching film

A technology of mulch and vinyl acetate, applied in coatings, plant protection covers, etc., can solve problems such as difficult recycling, refractory mulch degradation, soil and environmental damage, etc., to avoid white pollution, good moisture permeability, increase aggregate structure and The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

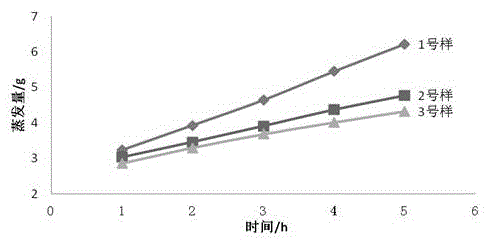

[0026] Example 1 Moisture retention test of plastic film

[0027] Take 3 parts of sand and weigh them separately. Sample No. 1 is a blank test site. Mix 6 parts by weight of vinyl acetate-ethylene-vinyl tert-carbonate with 94 parts by weight of water to uniformly make pulp, respectively according to 1kg / m 2 and 1.5kg / m 2 Spray on the surface of No. 2 and No. 3 sandy soil, and form a plastic film after the surface of No. 2 and No. 3 samples is solidified, and spray the same amount of water on the 3 samples. Then place the sample in sunny weather with high temperature to dry naturally, weigh every 1 hour, and calculate the evaporation of the sample.

[0028] Take 3 parts of sand and weigh them separately. Sample No. 1 is a blank test site. Mix 4 parts by weight of vinyl acetate-vinyl tert-carbonate-maleic acid ester with 96 parts by weight of water to make pulp uniformly, respectively according to 1kg / m 2 and 1.5kg / m 2 Spray on the surface of No. 2 and No. 3 sandy soil, a...

Embodiment 2

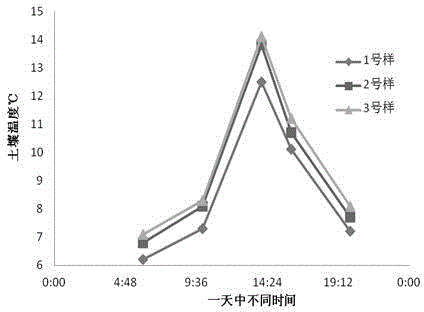

[0032] Embodiment 2 insulation test

[0033] Draw 3 blocks of 10m in a certain outdoor plot 2 The first piece of land was used as a blank test. On the second piece of land, use 15 parts of vinyl acetate-ethylene-vinyl tert-carbonate emulsion and 85 parts of water to uniformly mix the emulsion according to 1.5kg / m 2 Spray evenly on the surface of the land to cure the conjunctiva. On the third piece of land, use 15 parts of vinyl acetate-ethylene-vinyl tert-carbonate emulsion and 85 parts of water to uniformly mix the emulsion according to 3kg / m 2 Spray evenly on the surface of the land to cure the conjunctiva. The thermometers were inserted 10cm below the surface of the three lands, and the temperature of the three soils was recorded at the same time every hour, and the soil temperature and time curves were obtained as shown in figure 2 . The test results show that the temperature of the soil sprayed with the emulsion is 0.4-1.6°C higher than that of the soil without the ...

Embodiment 3

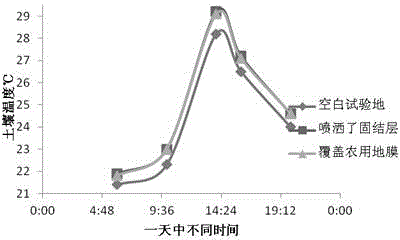

[0035] Embodiment 3 replaces traditional plastic mulch test

[0036] Draw the same three equal parts on the land, fertilize and water first during the sowing season, then sow corn on demand, and finally cover the soil. The first part of the land is used as a blank test, and 6 parts of vinyl acetate-acrylic octyl Mix ester copolymer emulsion and 94 parts of water evenly, according to 2kg / m 2 The dosage is sprayed on the soil surface, and the third piece of land is covered with general agricultural plastic mulch. Three points of land respectively insert the thermometer 10cm below the surface. According to the management of traditional agricultural planting methods, the soil temperature is measured regularly, and the emergence rate of corn is recorded. According to the test, the maize emergence rate in the test site 1 was 82%, that in the test site 2 was 98%, and that in the test site 3 was 97.5%. The soil temperature and time curve obtained from the test is shown in image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com