High-temperature coal gas filtering and purifying device and method for static bed

A technology for filtering and purifying gas, applied in the direction of gas dust removal, etc., can solve problems such as environmental pollution, and achieve the effects of ensuring purity, increasing furnace temperature and high filtering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

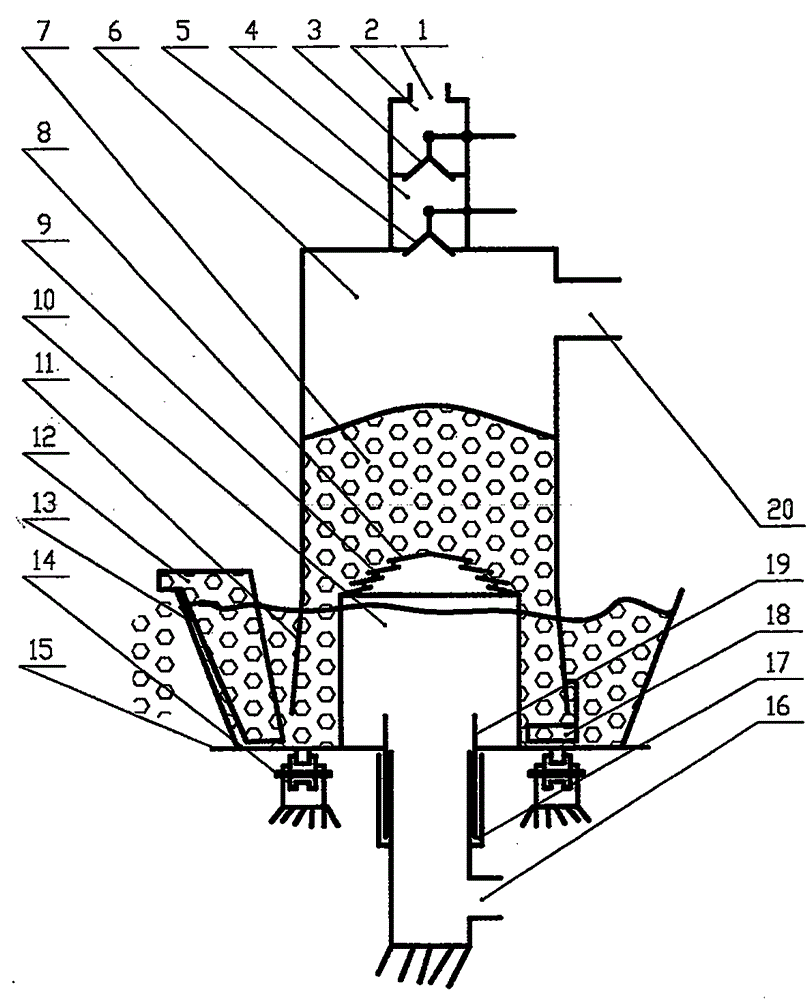

[0014] The device is divided into three steps: feeding, filtering, and slag removal.

[0015] The filter material falls into the primary feeding box 2 through the filter material inlet 1, the primary sealing bell jar 3 is opened, the filter material falls into the secondary feeding box 4, the primary sealing bell jar 3 is closed, and the secondary sealing bell jar 5 is opened. The filter material falls into the 6 cavities of the main body. In this way, the primary sealing bell jar 3 and the secondary sealing bell jar 5 are switched alternately to achieve the purpose of sealing the feeding process.

[0016] The filter material is supported by the top and side of the tower grid 8 in the cavity of the main body 6, and the tower grid 8 is provided with a multi-stage annular gas channel 9.

[0017] The crude gas enters the gas box 10 through the crude gas inlet 15 and through the annular water seal groove 17 . Enter the filter material layer 7 through the annular gas passage 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com