Preparation method of metal/aluminum oxide solar selective absorption coating material

A technology of absorbing coatings and alumina, applied in coatings, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of low light-to-heat conversion efficiency of coating materials, unreasonable coating structure design, and coating preparation Incomplete process and other problems, to achieve the effect of no obvious performance attenuation, reasonable coating structure design, and small changes in absorptivity and emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

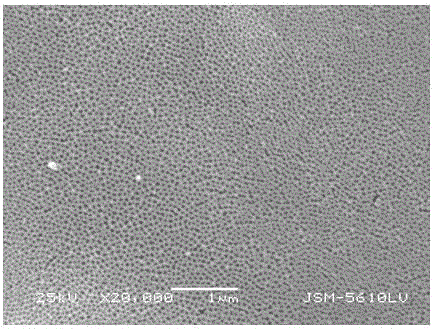

[0036] (1) Prepare a porous alumina template; specifically include the following sub-steps:

[0037] (1.1) Under the condition of temperature of 20°C and oxidation voltage of 20V, put the high-purity aluminum sheet in 0.3M oxalic acid solution for anodic oxidation for 6 hours;

[0038] (1.2) Put the aluminum sheet that has passed step (1.1) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 6 hours;

[0039] (1.3) Under the conditions of a temperature of 20°C and an oxidation voltage of 20V, anodize the aluminum sheet in step (1.2) in a 0.3M oxalic acid solution for 12 hours;

[0040] (1.4) Put the aluminum sheet that has passed step (1.3) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 12 hours;

[0041] (1.5) with saturated CuCl 2 solution to replace the aluminum layer on the back of the aluminum sheet; use 5wt% phosphoric acid solution to corrode the aluminum sheet at 60°C for...

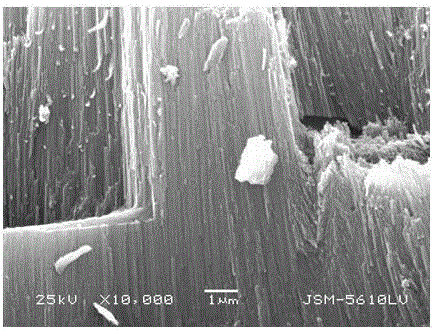

Embodiment 2

[0049] (1) Prepare a porous alumina template; specifically include the following sub-steps:

[0050] (1.1) Place the high-purity aluminum sheet in 0.3M oxalic acid solution for anodic oxidation for 6 hours at a temperature of 20°C and an oxidation voltage of 40V;

[0051] (1.2) Put the aluminum sheet that has passed step (1.1) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 6 hours;

[0052] (1.3) Under the conditions of a temperature of 20°C and an oxidation voltage of 40V, anodize the aluminum sheet in step (1.2) in a 0.3M oxalic acid solution for 12 hours;

[0053] (1.4) Put the aluminum sheet that has passed step (1.3) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 12 hours;

[0054] (1.5) with saturated CuCl 2 solution to replace the aluminum layer on the back of the aluminum sheet; use 5wt% phosphoric acid solution to corrode the aluminum sheet at 60°C for 10-20 minutes...

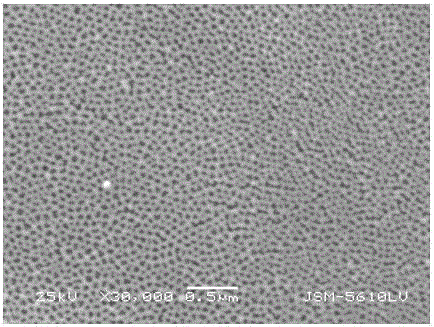

Embodiment 3

[0062] (1) Prepare a porous alumina template; specifically include the following sub-steps:

[0063] (1.1) Place the high-purity aluminum sheet in 0.3M oxalic acid solution for anodic oxidation for 6 hours at a temperature of 40°C and an oxidation voltage of 20V;

[0064] (1.2) Put the aluminum sheet that has passed step (1.1) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 6 hours;

[0065] (1.3) Under the conditions of a temperature of 40°C and an oxidation voltage of 20V, anodize the aluminum sheet in step (1.2) in a 0.3M oxalic acid solution for 12 hours;

[0066] (1.4) Put the aluminum sheet that has passed step (1.3) in a mixture of 5wt% phosphoric acid and 2wt% chromic acid, and chemically corrode it at 60°C for 12 hours;

[0067] (1.5) with saturated CuCl 2 solution to replace the aluminum layer on the back of the aluminum sheet; use 5wt% phosphoric acid solution to corrode the aluminum sheet at 60°C for 10-20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com