Well wall structure and construction method of a water-bearing rock formation

A construction method and shaft wall technology, applied in shaft equipment, earthwork drilling, shaft lining, etc., can solve the problems of unused surrounding rock mass bearing capacity, accumulation, peeling, etc., to improve compactness and bond strength, reduce The effect of thin well wall and lower engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: The bottom plate is an inclined shaft wall structure with an inverted arch type

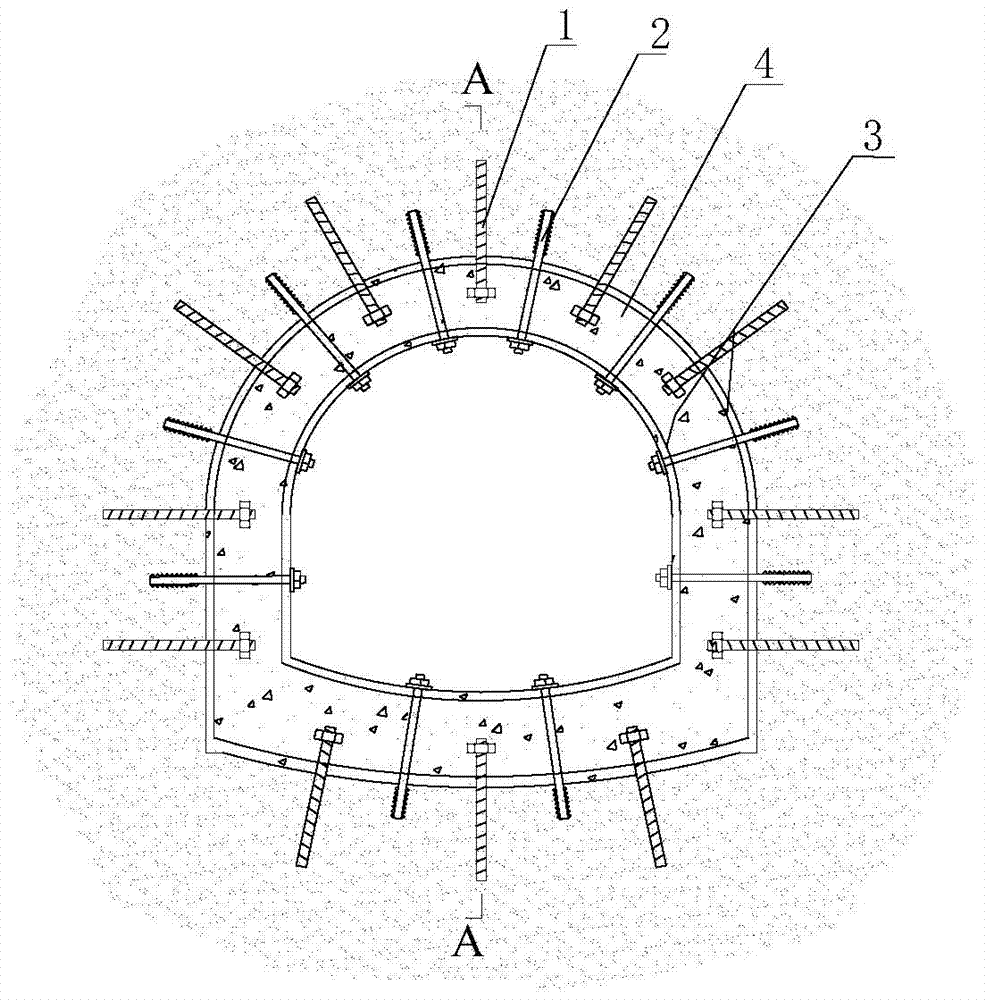

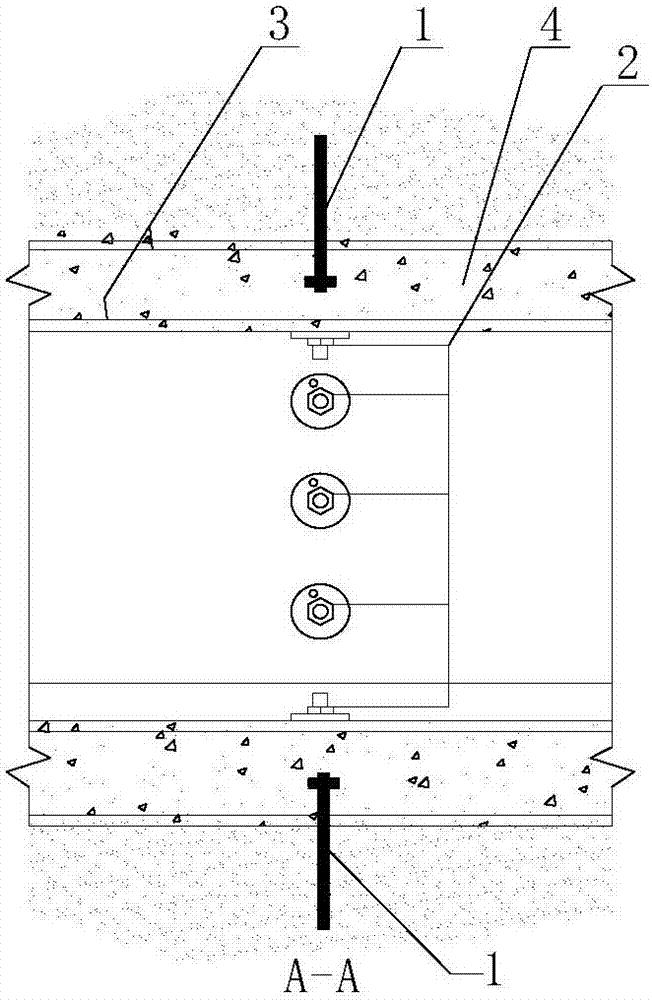

[0047] The bottom plate of the present invention is a flat inclined shaft wall structure, which is composed of anchor rod I1, anchor rod II2, steel skeleton 3, and concrete 4 (see Picture 1-1 , Figure 1-2 ).

[0048] Specific construction steps:

[0049] (1) After the wellbore of the inclined shaft in the aquifer is excavated, firstly, according to a certain axial and circumferential distance, drill holes in the surrounding rock mass and install the anchor rods I1 and II2; the outer end of the anchor rod I1 extends into the inside of the well wall 4 Instead of penetrating the shaft wall, the outer end of the anchor rod II2 penetrates the shaft wall concrete 4 just to reach its inner surface;

[0050] (2) Carry out the binding construction of the shaft wall steel skeleton 3, and firmly connect with the anchor rods I1 and II2 to form a three-dimensional steel skeleton, and con...

Embodiment 2

[0055] Embodiment 2: the bottom plate is a straight type inclined shaft wall structure;

[0056] The bottom plate of the present invention is a flat inclined shaft wall structure, which is composed of anchor rod I1, anchor rod II2, steel skeleton 3, and concrete 4 (see diagram 2-1 , Figure 2-2 ).

[0057] Others are the same as in Example 1.

Embodiment 3

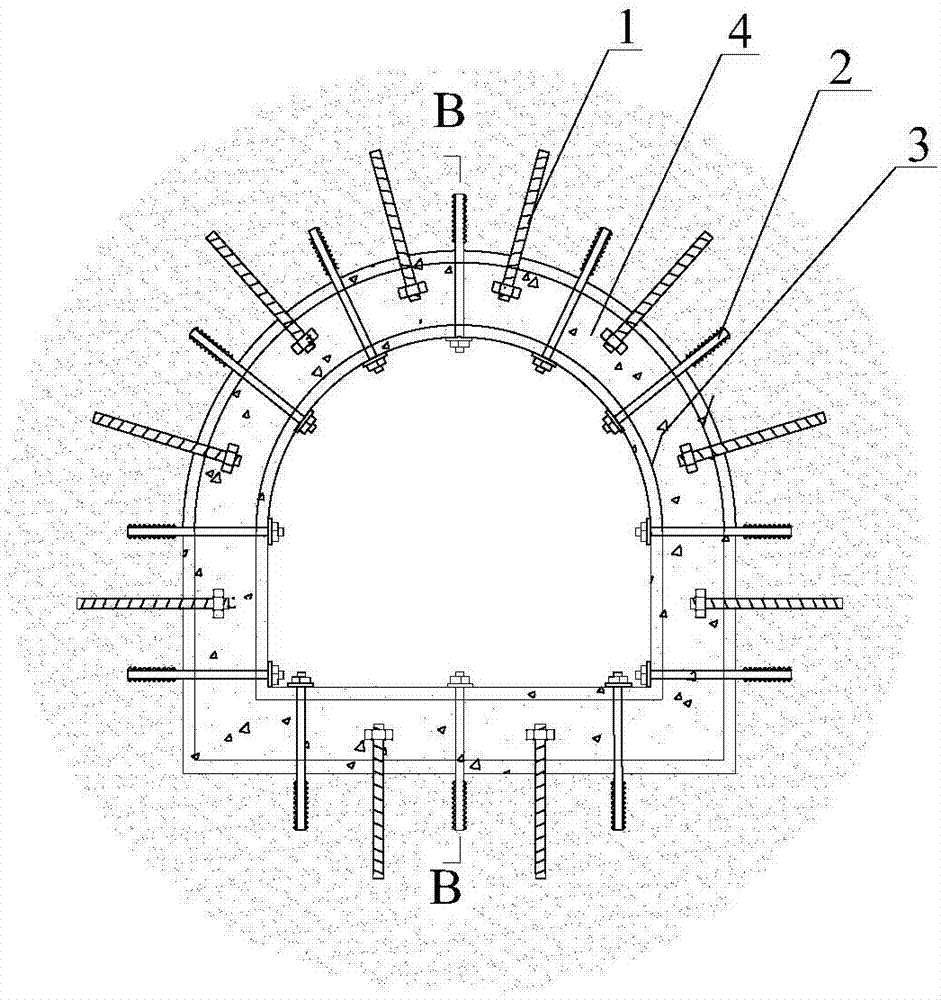

[0058] Embodiment 3: shaft wall structure;

[0059] The shaft wall structure of the present invention is composed of anchor rod I1, anchor rod II2, steel skeleton 3, and concrete 4 (see Figure 3-1 , Figure 3-2 ).

[0060] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com