Method and device for burning pulverized coal or pulverized coal to generate high-temperature high-oxygen torch ignition

A torch and coal crushing technology, which is applied in the directions of combustion ignition, combustion method, and ignition through the guide flare, can solve the problems of easy coking and large pre-combustion chamber volume in the coal-fired pre-combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

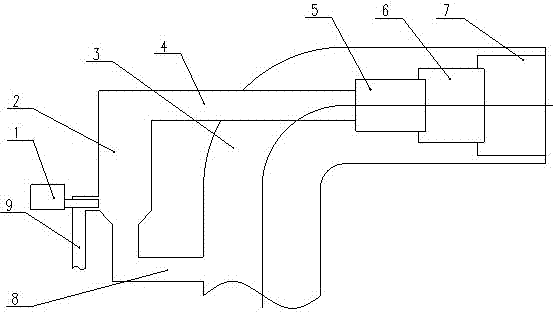

[0048] Embodiment 1: as figure 1 As shown, the device of the present invention includes: plasma generator I1, pre-combustion chamber I2, main burner 3, torch outlet I4, primary cylinder 5, secondary cylinder 6, third-stage cylinder 7, primary air duct 8 of pre-combustion chamber , Pre-combustion chamber secondary air duct 9.

[0049] The lower part of the pre-combustion chamber I2 is a constricted opening, through which the primary air duct 8 of the pre-combustion chamber is connected. The secondary air duct 9 of the combustion chamber and the secondary air duct 9 of the pre-combustion chamber are provided with an elbow before entering the pre-combustion chamber I2, and a hole is opened on the elbow, and the plasma generator I1 is inserted into the hole, and the upper part of the pre-combustion chamber I2 is connected to the torch Exit I4, the torch outlet I4 is smaller than the first-stage barrel 5, the right end of the torch outlet I4 is inserted into the first-stage barrel...

Embodiment 2

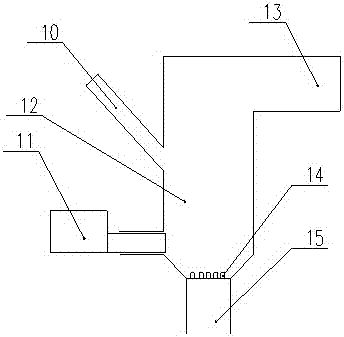

[0052] Embodiment 2: as figure 2 As shown, the pre-combustion chamber II12 is an adiabatic combustion chamber, which is generally arranged vertically. The lower part of the pre-combustion chamber II12 is connected to the wind cap 14, the lower part of the wind cap 14 is connected to the air inlet 15, the middle part of the pre-combustion chamber II12 is connected to the coal drop pipe 10, and the upper part of the pre-combustion chamber II12 is connected to the torch Exit II13.

[0053] Its working process: After the plasma generator Ⅱ11 heats the inner cavity of the pre-combustion chamber Ⅱ12, it puts crushed coal from the coal drop pipe 10 into the pre-combustion chamber Ⅱ12, and the smoke after ignition is ejected from the torch outlet Ⅱ13, and the combustion-supporting Air enters the pre-combustion chamber from the air inlet 15 through the air cap 14 to blow the pulverized coal into a fluidized state for fluidized combustion; by controlling the equivalent excess air coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com