Tab-free winding type lithium ion battery cell and manufacturing method thereof

A lithium-ion battery, electrodeless ear winding technology, applied in non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problem of winding batteries not being able to discharge at large currents, achieve good consistency, reduce internal resistance, The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

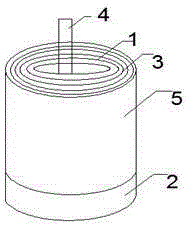

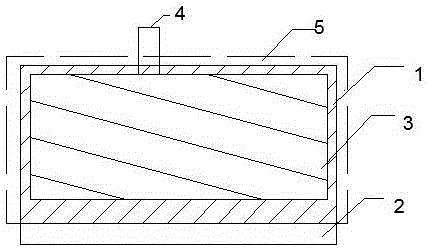

[0029] Embodiment 1: as Figure 1-4 As shown, a wound-type lithium-ion battery cell without tabs includes a positive electrode sheet 3 , a negative electrode sheet 1 and a separator 5 . The negative electrode sheet 1 includes a coated part and an uncoated blank 2, and the blank 2 is copper foil. And the blank space 2 is located at the bottom of the negative electrode sheet 1 with a width of 0.1mm--18mm. The upper end of the positive plate 3 is provided with a positive tab 4, and the positive tab 4 is an aluminum strip.

[0030] The positive electrode sheet 3, the separator 5 and the negative electrode sheet 1, the separator 5 are stacked in sequence, and the width and length of the negative electrode sheet 1 are ensured to be greater than the width and length of the positive electrode sheet 3 during the lamination process. The tab 4 of the positive electrode sheet 3 is exposed. The length of the diaphragm 5 is greater than the length of the negative electrode sheet 1, the u...

Embodiment 2

[0032] Example 2: A method of manufacturing a wound-type lithium-ion battery cell without tabs, 1), the positive electrode sheet is conventionally coated with a coating machine, and the negative electrode sheet is coated horizontally on both sides of the negative electrode sheet with a coating machine. Coating is carried out in the way of longitudinal intermittent coating to ensure that the negative electrode sheet can leave a blank space without coating in the vertical direction. The blank space is copper foil, and the width of the blank space is 01.mm-18mm.

[0033] 2) Cutting the coated positive electrode and negative electrode to form a strip-shaped electrode to ensure that there is a certain width of blank space at the bottom of the strip-shaped negative electrode, and the blank strips on both sides of the strip-shaped negative electrode are aligned; and The positive tab is welded to the upper end of the positive plate.

[0034] 3) The distance between the positive electr...

Embodiment 3

[0039] Embodiment 3: A manufacturing method of a wound-type lithium-ion battery cell without tabs. In the present invention, a cylindrical 18650 lithium-ion battery cell is taken as an example for specific description. According to the above method, the wound-type lithium-ion battery without tabs is produced as sample 1, and the specific process is as follows:

[0040] 1) The positive electrode sheet is prepared with slurry according to the conventional batching process, and then the prepared slurry is coated with a coating machine according to the process designed by 18650 to ensure that the thickness of the positive electrode sheet is 12 μm and the density of one side is 10mg / cm 2, the density of both sides is 20mg / cm 2 .

[0041] Negative plate installation The conventional batching process is used to configure the slurry, and then the prepared slurry is coated on both sides of the negative plate in the manner of horizontal continuous coating and vertical intermittent co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Single sided density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com