A valve body lost foam and its manufacturing method

A manufacturing method and technology of lost foam, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of labor consumption, unfavorable filling, waste of materials, etc., to save materials and labor, reduce post-processing costs, and delay solidification the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for manufacturing lost foam of a valve body, the specific steps include:

[0036] (1) Design the model with 3D software according to the drawing of the valve body, and use CAE analysis software to analyze, determine the appropriate model, and manufacture the corresponding mold;

[0037] (2) Pre-expandable polymethyl methacrylate resin beads;

[0038] (3) Use expandable polymethyl methacrylate resin beads to make a white mold of the valve body and dry it.

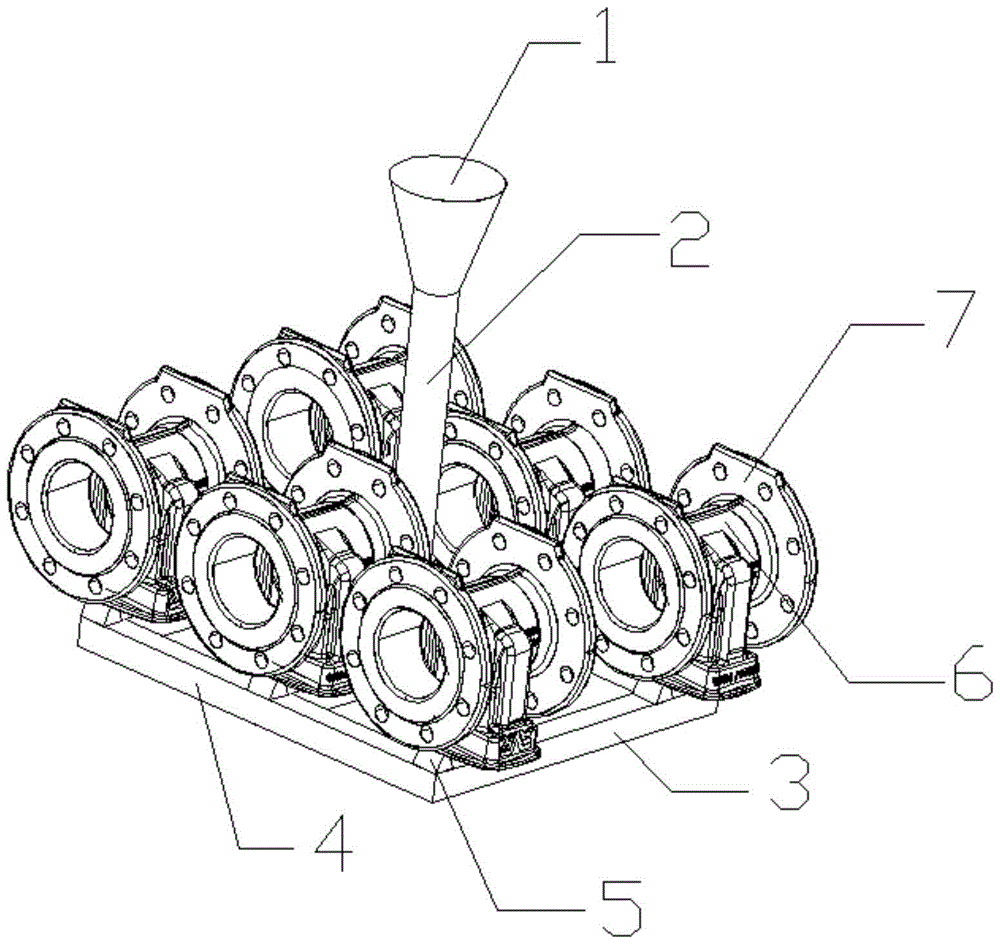

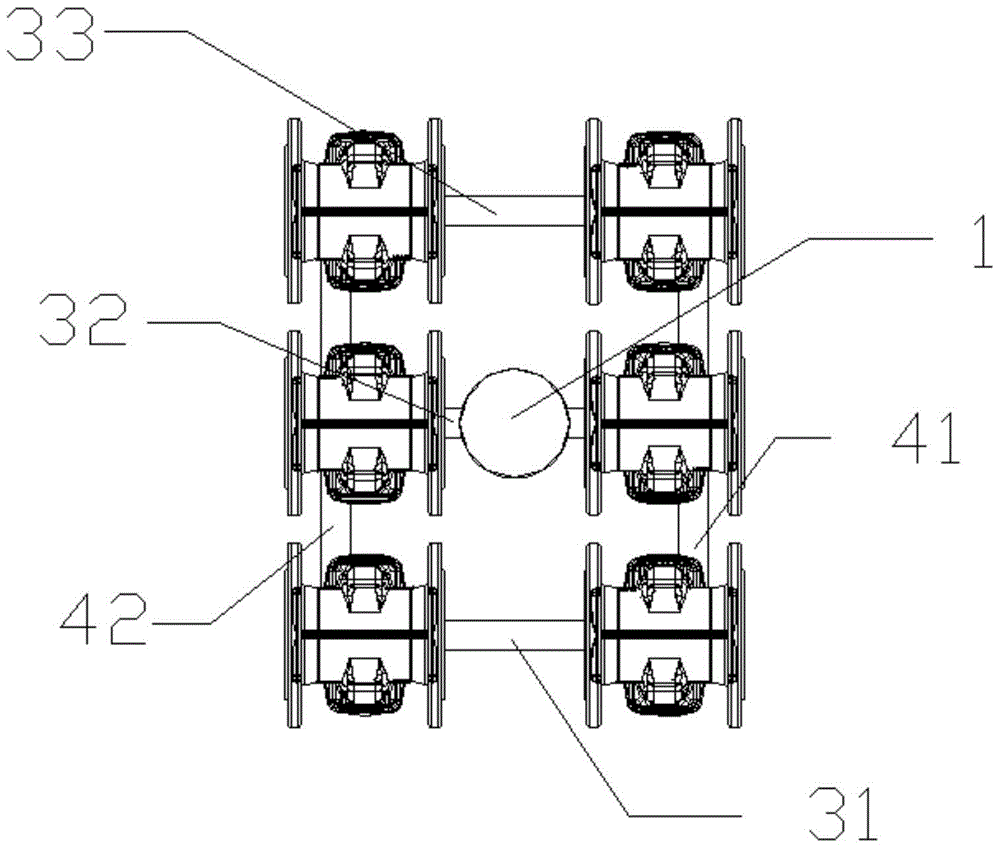

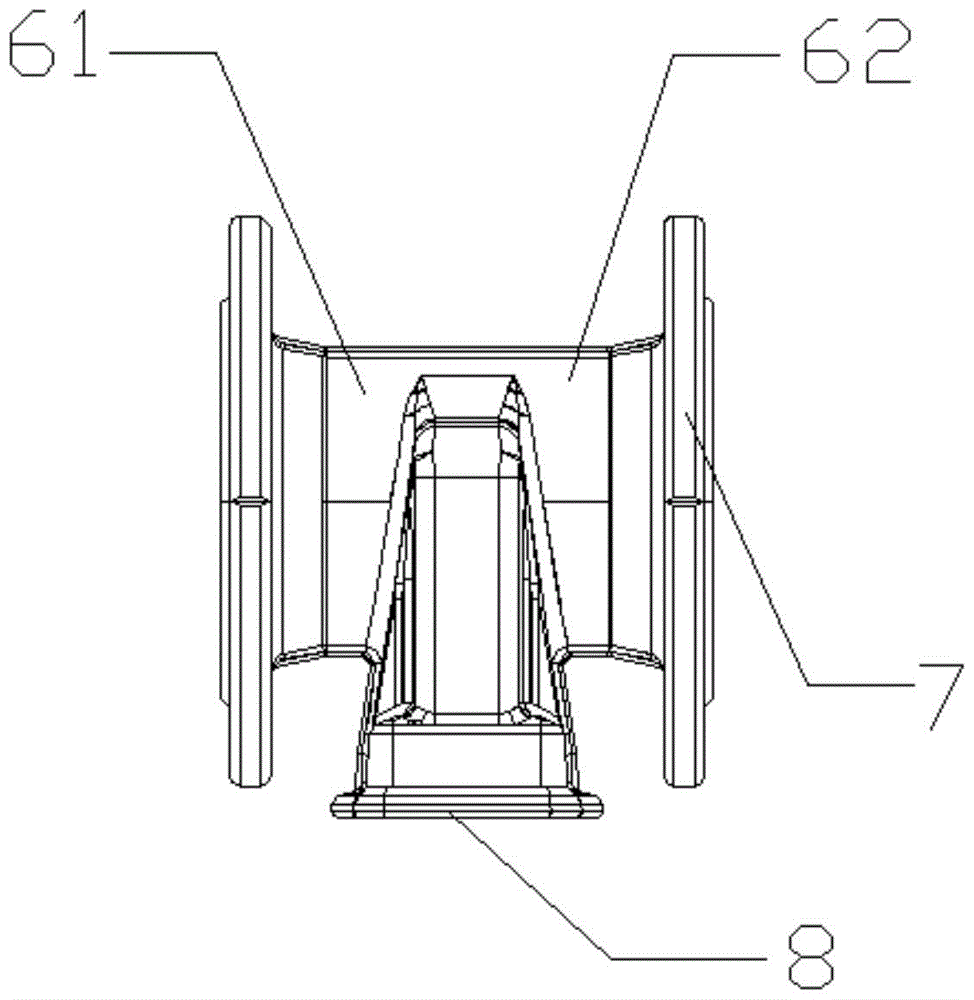

[0039] (4) In the square cavity of the white mold after molding, use expandable polymethyl methacrylate resin beads to make sprue 2, runner 3, vertical sprue 4, and inner gate 5. The runner 31, the second runner 32, and the third runner 33 are glued in parallel between the first runner 41 and the second runner 42, and the distance between each runner 3 is equal , The connection between each runner 3 and the down runner 4 is bonded to the inner gate 5, and the valve body is placed upside down above the inner gate 5, ...

Embodiment 2

[0050] A method for manufacturing lost foam of a valve body, the specific steps include:

[0051] (1) Design the model with 3D software according to the drawing of the valve body, and use CAE analysis software to analyze, determine the appropriate model, and manufacture the corresponding mold;

[0052] (2) Pre-expandable polymethyl methacrylate resin beads;

[0053] (3) Use expandable polymethyl methacrylate resin beads to make the white mold of the valve body, and put the white mold into the drying room, and adjust the temperature to 50-55°C for drying.

[0054] (4) In the square cavity of the white mold after molding, use expandable polymethyl methacrylate resin beads to make sprue 2, runner 3, vertical sprue 4, and inner gate 5. The runner 31, the second runner 32, and the third runner 33 are glued in parallel between the first runner 41 and the second runner 42, and the distance between each runner 3 is equal , The connection between each runner 3 and the down runner 4 is bonded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com