Automatic material reversing device

A technology for automatic material turning and turning of material plates, applied in metal processing and other directions, can solve problems such as material bending, and achieve the effects of reducing production costs, saving site resources, and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

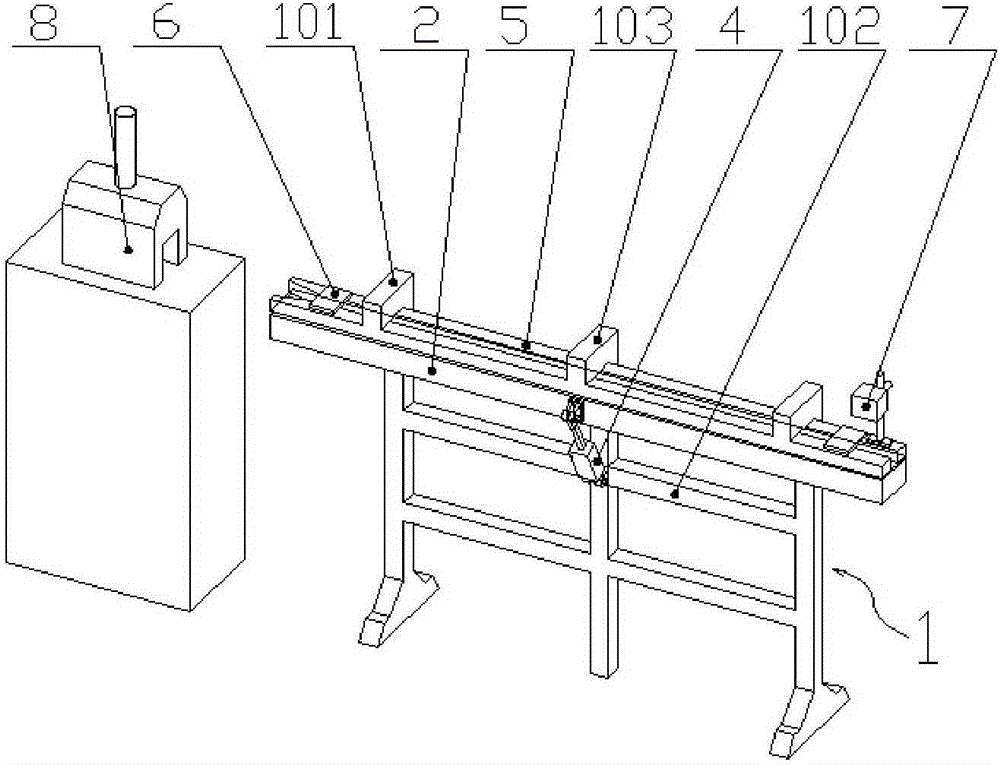

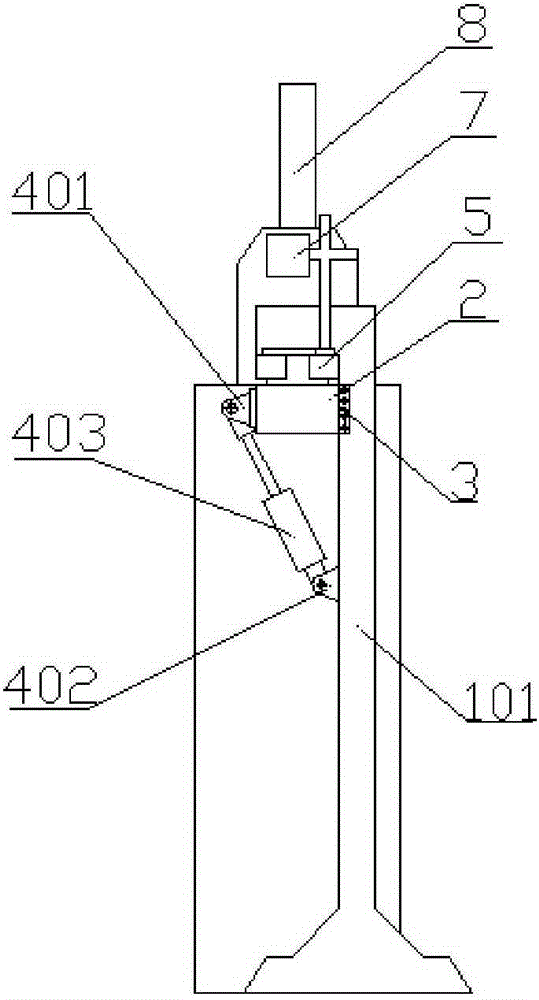

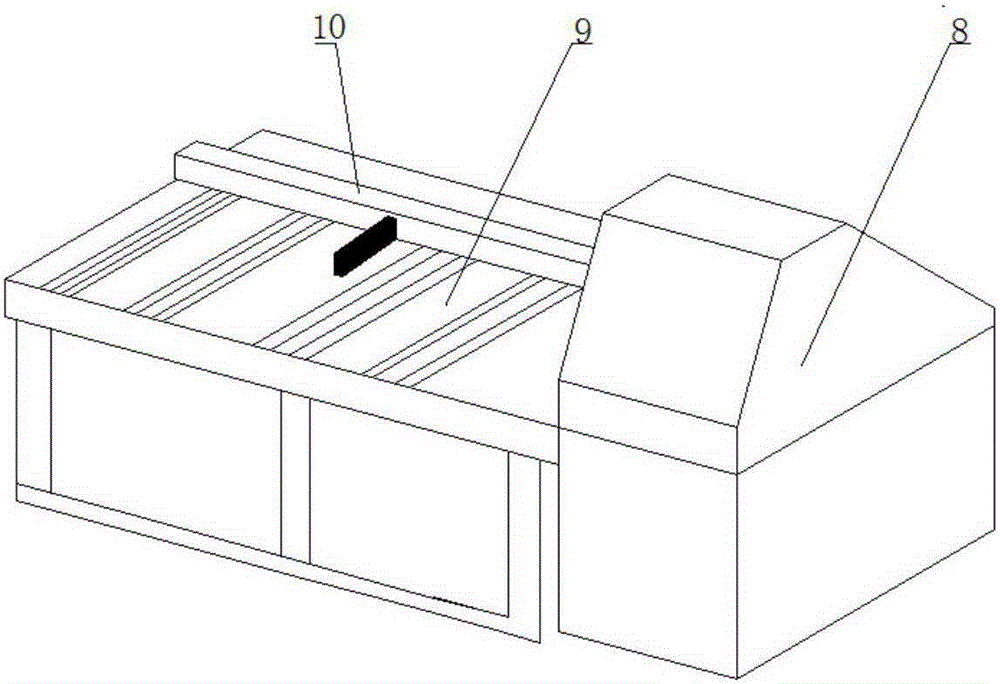

[0024] Such as Figure 1-2 As shown, the automatic material turning device provided by the present invention includes a frame body 1, a material turning plate 2 and a driving mechanism 4, and the material turning plate 2 is rotatably arranged on the frame body 1 through several hinges 3, and the driving The mechanism 4 is respectively connected with the frame body 1 and the turning plate 2; the frame body 1 is formed by connecting two legs 101 and at least one beam 102 in a criss-cross pattern, the upper end of the leg 101 is L-shaped, and the lower end The upper part is provided with a foot, and an upper plate 5 is arranged on the inner side of the short side of the L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com