Efficient nitrogen and phosphorus removal process suitable for low carbon-nitrogen ratio sewage

A technology for nitrogen and phosphorus removal and low carbon-to-nitrogen ratio, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, water pollutants, etc., can solve the problem of high cost of chemical nitrogen and phosphorus removal, carbon and nitrogen The ratio is low, the effluent water quality is difficult to meet the first-class A discharge standard, etc., and the treatment effect is good, the reflux ratio is reduced, and the treatment effect is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

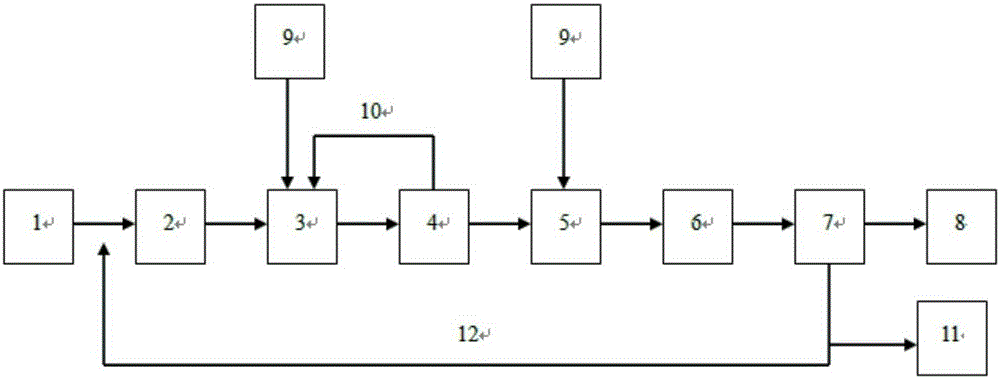

Method used

Image

Examples

Embodiment 1

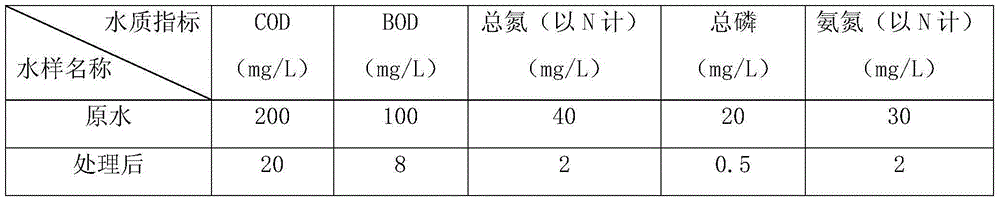

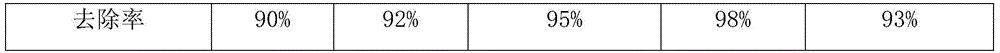

[0025] Example 1: The domestic sewage in urban quarters is treated by using the nitrogen and phosphorus removal process provided by the present invention, and the treatment effect is shown in Table 1.

[0026] Table 1 Treatment effect of a high-efficiency nitrogen and phosphorus removal process suitable for low carbon-to-nitrogen ratio sewage

[0027]

[0028]

[0029] Note: COD-chemical oxygen demand, BOD-biochemical oxygen demand

Embodiment 2

[0030] Example 2: The process of nitrogen and phosphorus removal provided by the present invention is used to treat school domestic sewage, and the treatment effect is shown in Table 2.

[0031] Table 2 Treatment effect of a high-efficiency nitrogen and phosphorus removal process suitable for low carbon-to-nitrogen ratio sewage

[0032]

[0033] Note: COD-chemical oxygen demand, BOD-biochemical oxygen demand

Embodiment 3

[0034] Example 3: The township domestic sewage was treated by using the nitrogen and phosphorus removal process provided by the present invention, and the treatment effect is shown in Table 3.

[0035] Table 3 Treatment effect of a high-efficiency nitrogen and phosphorus removal process suitable for low carbon-to-nitrogen ratio sewage

[0036]

[0037] Note: COD-chemical oxygen demand, BOD-biochemical oxygen demand

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com