Sliding discharge reactor for ignition and combustion assistance

An auxiliary combustion and reactor technology, which is applied in the aerospace field, can solve problems such as increased device complexity, unfavorable popularization and application, and insufficient combustion, and achieve the effects of improving combustion efficiency, simple device structure, and easy-to-use products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

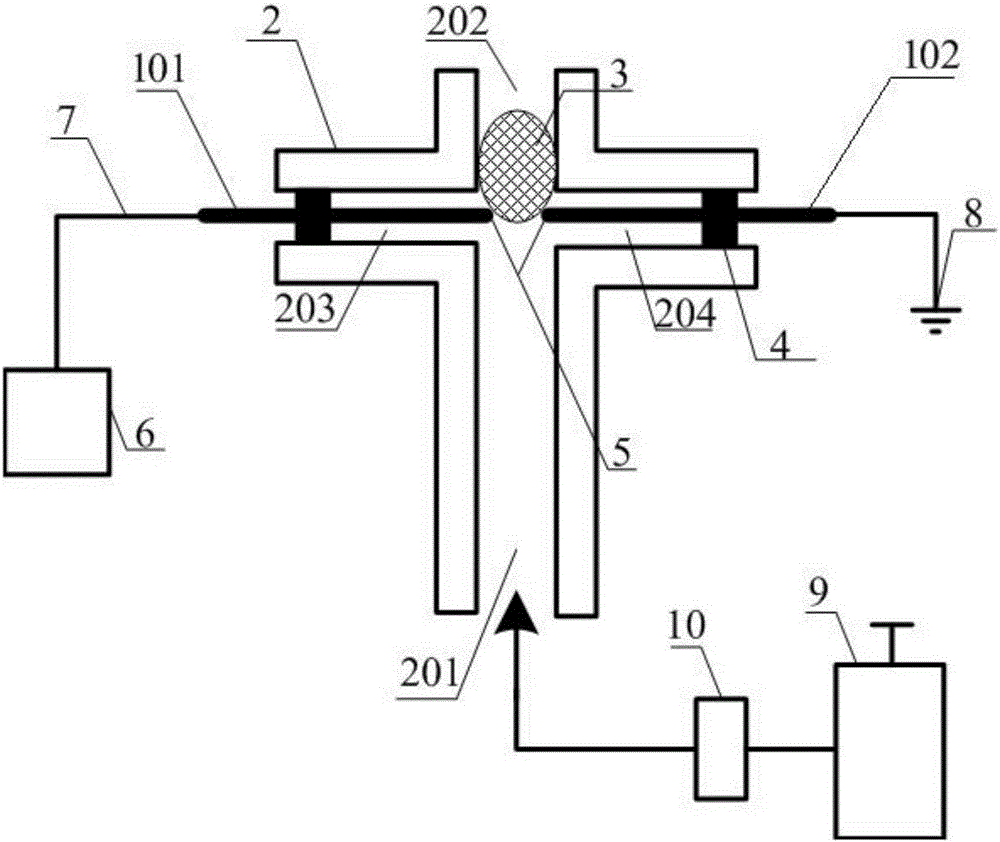

[0041] Example 1, such as figure 1 As shown, a sliding discharge reactor for ignition and auxiliary combustion according to the first embodiment of the present invention includes a combustion chamber, a gas path, an electric circuit, and the like. The combustion chamber is composed of a first sliding discharge electrode 101 , a second sliding discharge electrode 102 , a cross four-way tubular insulating device 2 , a combustion area 3 , adhesive glue 4 and an arcing end 5 . The gas from the gas source 9 passes through the gas flowmeter 10 and enters the combustion chamber through the air inlet 201 . The circuit is composed of a plasma excitation power supply 6 , a high voltage terminal 7 , a ground terminal 8 , a first sliding discharge electrode 101 , and a second sliding discharge electrode 102 . The combustible gas can be ignited and assisted by turning on the plasma excitation power supply 6 and the gas source 9 .

[0042]The cross cross four-way tubular insulating device...

Embodiment 2

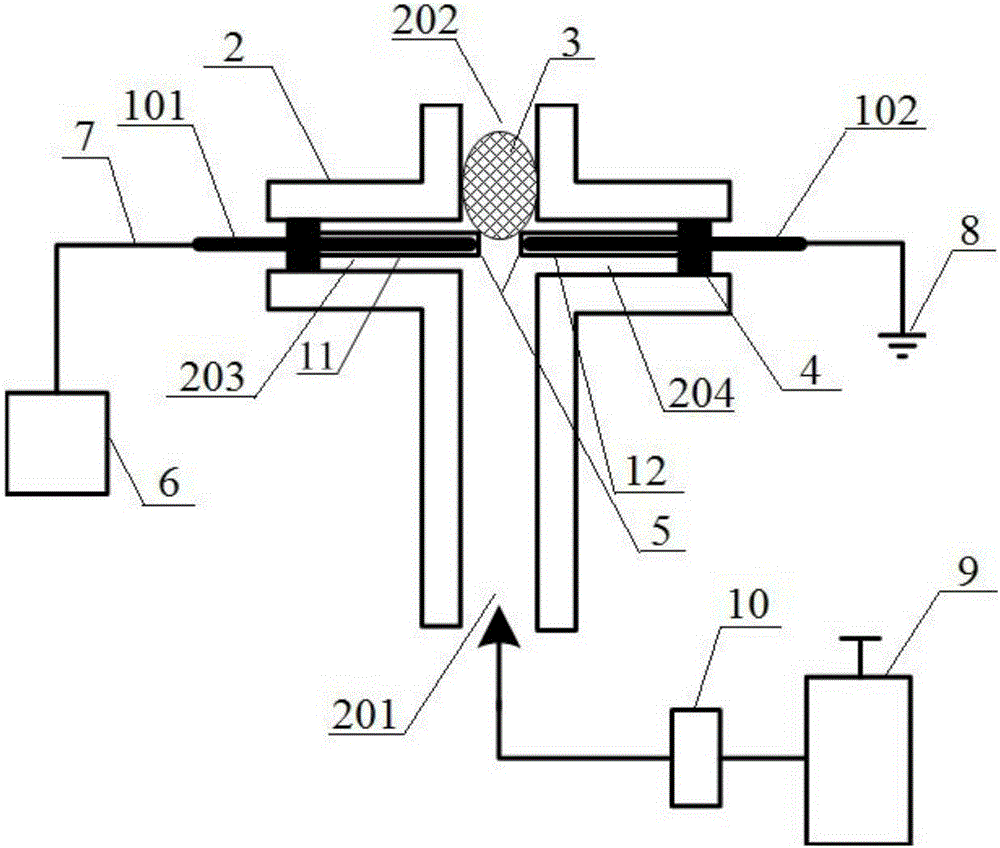

[0049] Example 2, such as figure 2 As shown, a sliding discharge reactor for ignition and auxiliary combustion of the second embodiment of the present invention is different from the first embodiment in that it also includes a first heat-resistant insulating device 11 and a second heat-resistant insulating device 12. The first heat-resistant insulating device 11 is a cavity with one end closed, and the discharge end of the first sliding discharge electrode 101 is inserted into the first heat-resistant insulating device 11 . The second heat-resistant insulating device 12 is a cavity with one end closed, and the discharge end of the second sliding discharge electrode 102 is inserted into the second heat-resistant insulating device 12 . The first heat-resistant insulating device 11 and the second heat-resistant insulating device 12 can perform dielectric barrier discharge (DBD). Since the dielectric barrier discharge has good uniformity and other characteristics, it can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com