A kind of polymer solar heat collector and its manufacturing method

A solar collector and polymer technology, applied in the field of collectors, can solve the problems of complex assembly, labor-intensive, low emission characteristics, etc., and achieve the effects of easy processing, improving production efficiency, and avoiding heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

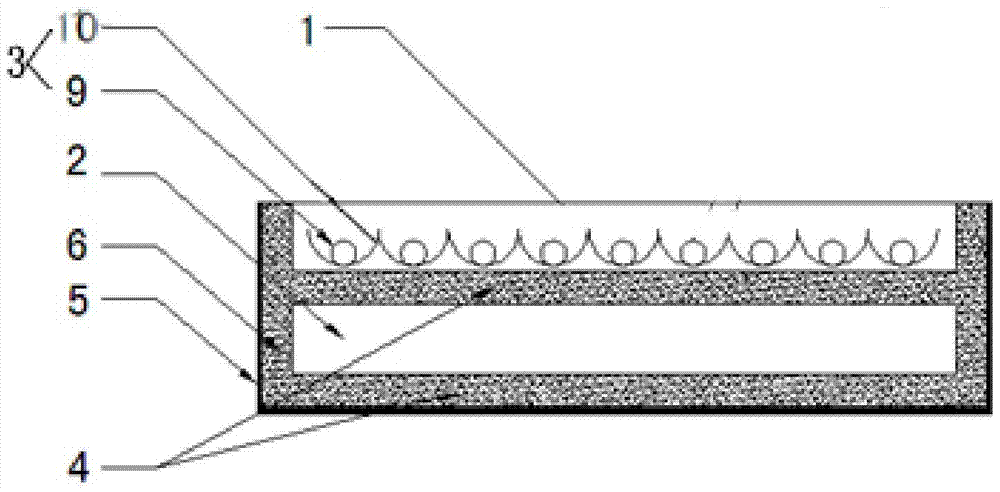

[0089] like figure 1 The concentrating polymer solar heat collector shown includes a cover plate 1 and a frame 6 . A polymer heat-absorbing plate core 3 is installed in the frame 6 . A water tank 2 is installed on the back side of the polymer heat-absorbing plate core 3 . Polymer insulation material 4 is filled between the frame 6 and the polymer heat-absorbing plate core 3 , between the polymer heat-absorbing plate core 3 and the water tank 2 , and between the frame 6 and the water tank 2 . A protective coating 5 is sprayed on the outside of the frame 6 .

[0090] The polymer heat-absorbing plate core 3 is composed of several heat-absorbing tubes 9 and several light-gathering grooves 10 . The heat-absorbing pipes 9 are correspondingly installed in the light-gathering groove 10, and several heat-absorbing pipes 9 are connected to form a heat-absorbing circuit. The heat-absorbing tube 9 is coated with a highly selective heat-absorbing coating capable of generating various a...

Embodiment 2

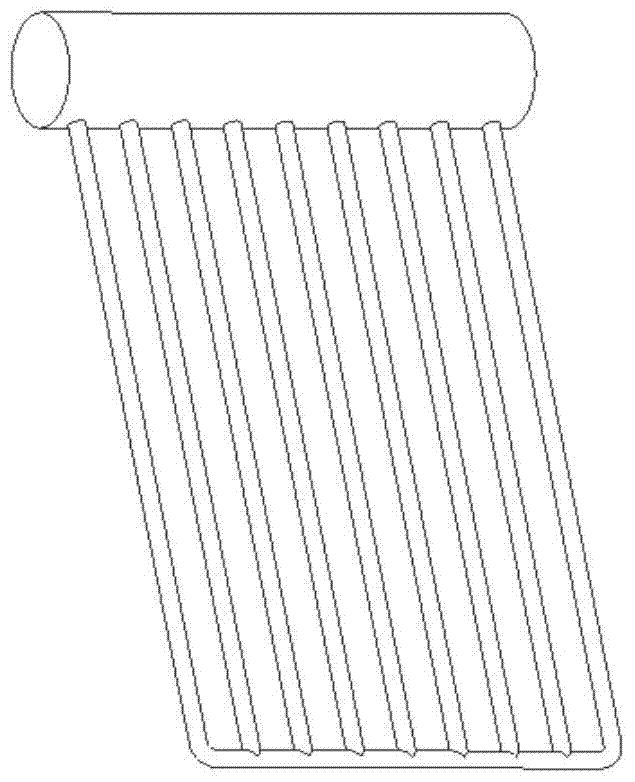

[0107] When the heat collector is a concentrating polymer solar heat collector, the heat collector can also be composed of several light concentrating structures in a linear structure arranged side by side. At this time, the collector is a one-dimensional all-polymer solar concentrator.

[0108] Several light concentrating structures in a linear structure are arranged side by side to form a one-dimensional all-polymer solar concentrating heat collector. like Figure 17 As shown, the light concentrating structure includes a fluid channel 17 and a polymer light-absorbing layer 16 wrapped outside the fluid channel 17, and a polymer light-absorbing film 14 is also provided outside the polymer light-absorbing layer 16, and the polymer light-absorbing film 14 and the polymer light-absorbing film A light-transmitting layer 15 is also provided between the layers 16, and a highly selective heat-absorbing coating that can exhibit multiple colors is provided on the polymer light-absorbi...

Embodiment 3

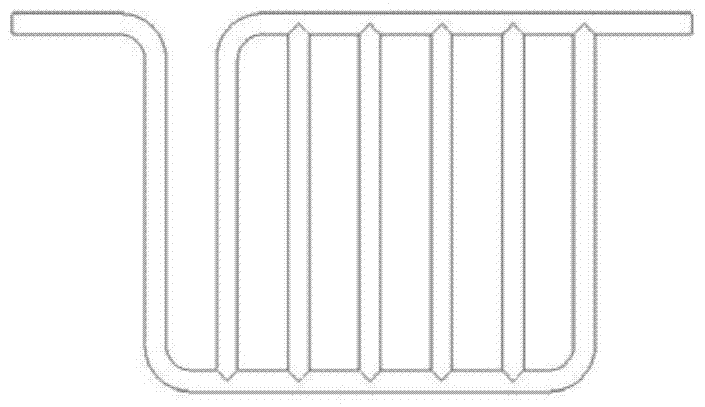

[0120] like Figure 22-23 In the full-channel polymer solar collector shown, the polymer heat-absorbing plate core 3 includes a shell, and several heat-absorbing flow channels are processed in the shell, and several heat-absorbing flow channels are connected to form a heat-absorbing circuit.

[0121] The structure of the polymer heat-absorbing plate core 3 can be any one of planar structure, wave structure or arc structure. like Figure 24 As shown, the schematic diagram of the structure of a full-channel polymer solar collector with a wave-shaped polymer heat-absorbing plate core.

[0122] The heat-absorbing flow channel is coated with a highly selective heat-absorbing coating that can exhibit various colors. The absorption rate of the prepared polymer heat-absorbing plate core with high selective absorption and low emission characteristics is greater than 90%, and the emissivity is less than 30%, which is obviously improved compared with the 80% of the existing heat-absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com