Synchronization measurement device for wall-adherent jet speed field and concentration field and method

A wall-attached jet and synchronous measurement technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the oxygen component concentration field cannot be obtained in real time, and the jet velocity field is difficult to obtain accurately, so as to solve the problem of easily disturbing the flow field and avoid mutual interference , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

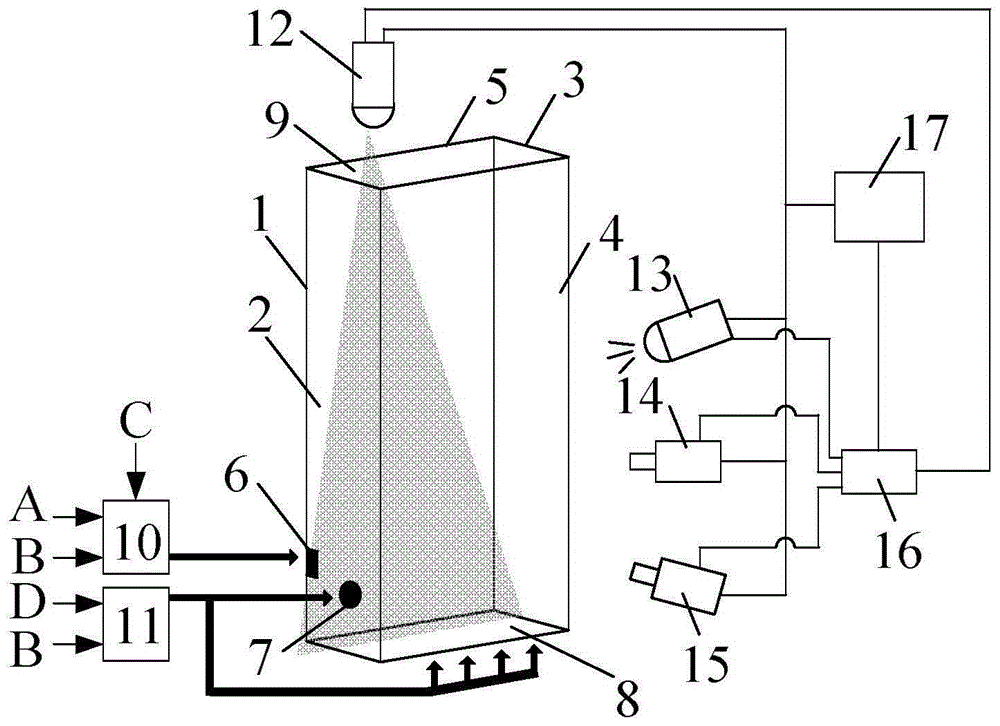

[0039] Refer to the following Figure 1~2 The implementation of the present invention will be described in detail. This embodiment is carried out on the premise of this technical solution, and the detailed implementation and operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

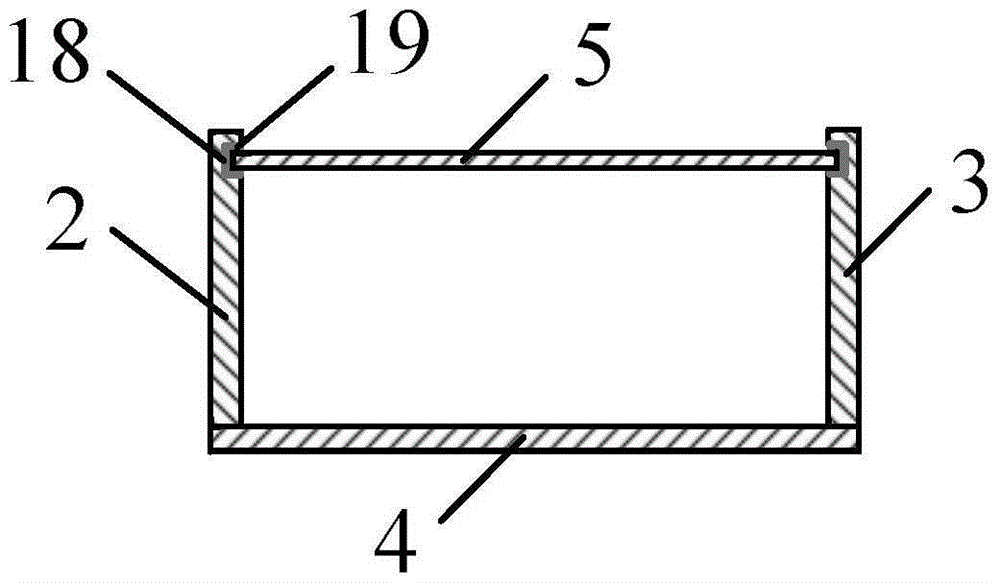

[0040] (1) Make a simultaneous measurement device for the velocity field and concentration field of the wall-attached jet. Use a rubber plate with a size of 500mm×100mm×15mm as the left side plate 2, a long groove (that is, groove 18) with a length of 10mm and a height of 7mm, and paste sealing mats on the three walls in the groove. Offer a jet nozzle with a diameter of 20mm (as the jet gas inlet 6) and a swirl nozzle with a diameter of 25mm (as the swirl gas inlet 7) at the height of 2100mm on the left side plate, and the distance between the two is 60mm. Use a high-purity transparent plexiglass plate with a size of 500mm×100mm×1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com