Long base stress sensor for hull structure and method of use

A stress sensor and sensor technology, which is applied in the direction of measuring the force of change in optical properties of materials when they are stressed, can solve the problems of large loading capacity and complex operating conditions of ocean-going ships, and achieve simple cable laying and improved water tightness. security and anti-vandal function, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

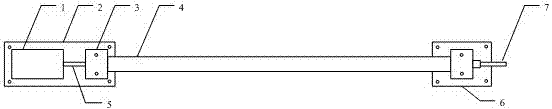

[0040] The long-base stress sensor for ship hull structure is characterized in that the sensor system includes: stress sensitive device, pre-fixed device, adjustment device, sealing device, installation tool;

[0041] The stress-sensitive device is composed of a single fiber grating 7, the two ends of the fiber grating are pasted on the movable plate 2 of the sensor base, and the pre-tension value of the fiber grating is corrected by the top wire, and the watertight flange is connected to the transmission optical cable. The stress of the structure is displayed at the demodulator end in the form of the wavelength change of the fiber grating, and the maximum measurable deformation is 2000 , the deformation of the fiber grating is basically linearly related to the wavelength change of the fiber grating.

[0042] Compensation algorithm, the wavelength of the fiber finally obtained is proportional to the stress value of the ship structure;

[0043] The pre-fixing device includes a...

Embodiment 2

[0048] The long-base stress fiber grating sensing for ship hull structure includes a sensor top seat 3 and a sensor base fixing plate 6, and a protection tube 4 is installed between the two bases 3 and 6. The fiber grating 7 passes through the protection tube 4, passes through the retractable connecting tube 5, and then enters the sealing box cover 1, and the top wire inside the sealing box cover 1 tightens the fiber grating.

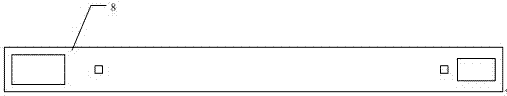

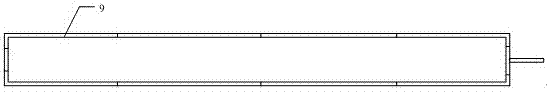

[0049] After the sensor is fixed on the hull by the installation tool 8, the sensor cover 9 is installed as a whole, and the bolts are locked.

[0050] (1) The fixed seat 6 is a component that reflects the good water tightness of the long-base stress sensor, and a multi-layer sealing ring is arranged in the circle of the front end of the optical fiber flange seat of the optical fiber 7;

[0051] (2) figure 2 The installation tool is an aluminum plate, which has the function of aligning the long-base stress sensor, because if the sensor installation an...

Embodiment 3

[0055] Methods of use include:

[0056] (1) When the hull changes under the external or internal force, inside the sealed sensor, the sensor top seat 3 and the sensor base fixing plate 6 undergo relative displacement, and the optical fiber fixed between the two bases 3 and 6 The grating 7 is deformed by the tensile force, resulting in the change of the wavelength of the laser light transmitted in the fiber grating 7 .

[0057] (2) The stress of the final hull structure is displayed on the demodulator end in the form of the wavelength change of the fiber grating 7. The deformation of the fiber grating and the wavelength change of the fiber grating 7 are basically linear. A linear relationship is obtained between the wavelength of the optical fiber and the stress value of the ship structure, and the results show that:

[0058] (1) The installation length of the sensor is 1.5m, and the deformation is generated by the spiral micrometer, and the spiral micrometer changes by 5mm pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com