Test fixture of light-emitting element

A technology for light-emitting components and test fixtures, which is used in optical instrument testing, machine/structural component testing, and measuring devices. The effect of preventing damage and efficient testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

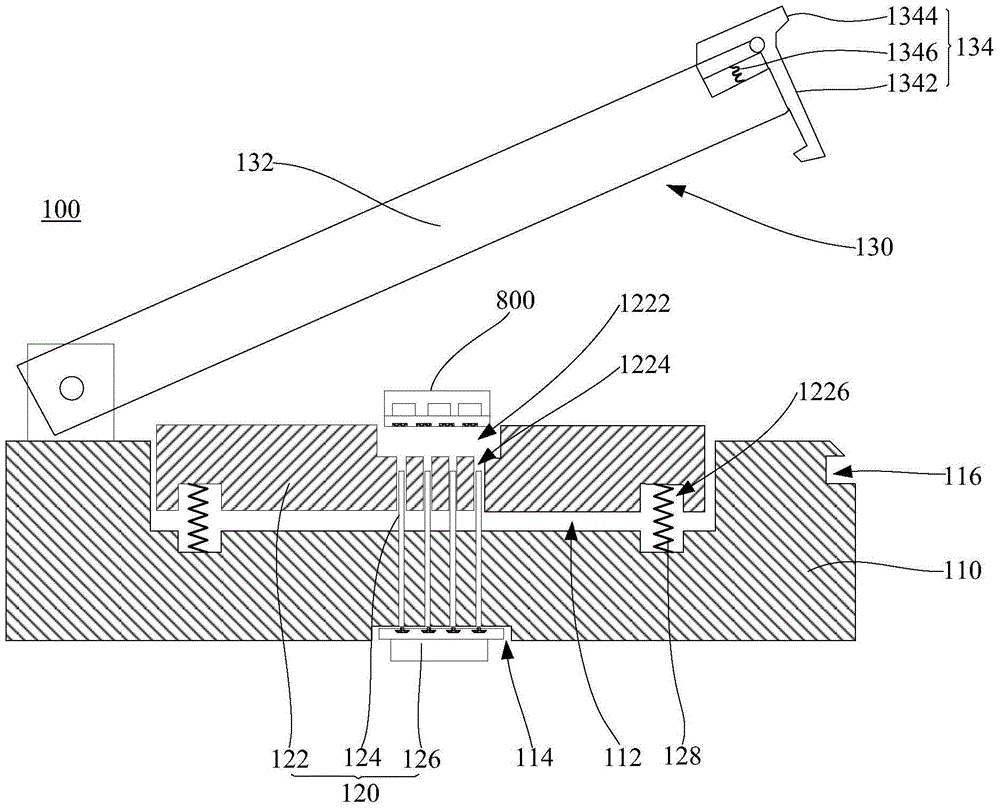

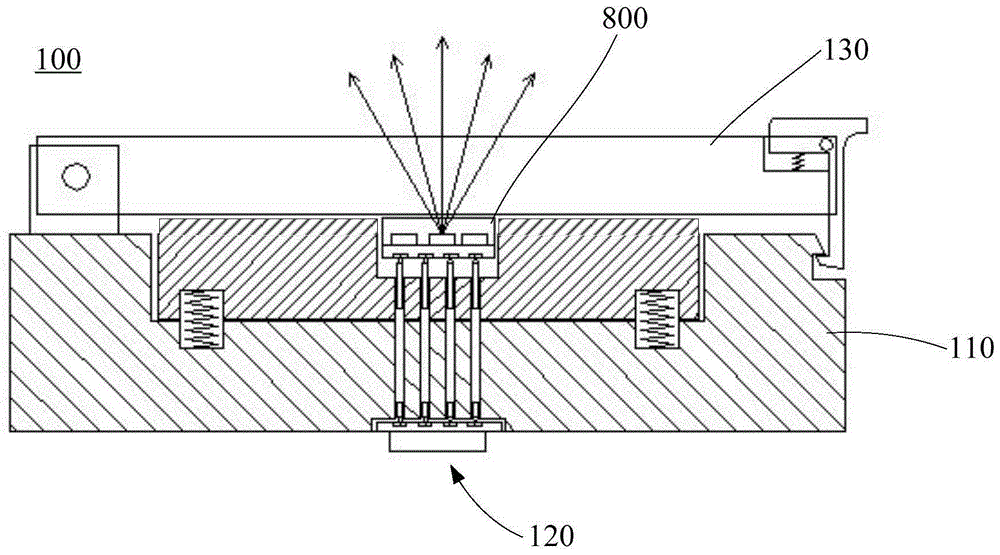

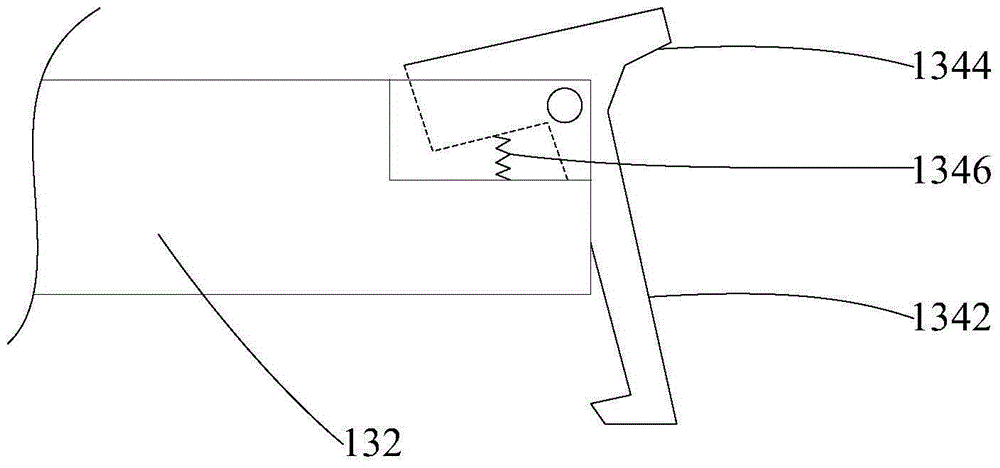

[0044] Please combine figure 1 , figure 2 with image 3, the light-emitting device testing fixture 100 of the first embodiment includes a base 110 , a testing component 120 and a limiting component 130 . The light-emitting element test fixture 100 of this embodiment is mainly used for performance testing of the light-emitting element 800 to be tested with a bottom pad, for example, performing an optical performance test on a surface-mounted LED with a bottom pad.

[0045] The upper surface of the base 110 is provided with a mounting slot 112 , and the lower surface is provided with a PCB connection position 114 .

[0046] The test assembly 120 includes a test substrate 122 , test probes 124 and a PCB test board 126 .

[0047] The test substrate 122 is disposed in the installation groove 112 . A test slot 1222 for placing the light-emitting element 800 to be tested is defined on the upper surface of the test substrate 122 . The base 110 and the test substrate 122 are prov...

Embodiment 2

[0061] Please combine Image 6 with Figure 7 , the light emitting device testing fixture 200 includes a base 210 , a testing component 220 and a limiting component 230 . The light-emitting element testing fixture 200 of the second embodiment is also mainly used for the optical performance test of the light-emitting element 800 to be tested with a bottom pad, and its structure is basically the same as that of the light-emitting element testing fixture of the first embodiment. The difference from Embodiment 1 is that the limit assembly 230 of the light-emitting element test fixture 200 in Embodiment 2 is different from the limit assembly 130 in Embodiment 1, and the structure of the corresponding base 210 and the arrangement of the test probes 224 are also different. ,details as follows:

[0062] The limiting assembly 230 of the second embodiment includes a clamping arm 232 , a clamping screw 234 and a return spring 236 .

[0063] The clamping arm 232 has a first abutting ar...

Embodiment 3

[0070] Please combine Figure 8 with Figure 9, the light-emitting device testing fixture 300 of Embodiment 3 includes a base 310 , a testing component 320 and a limiting component 330 . The light-emitting element testing fixture 300 of Embodiment 3 is mainly used for performance testing of the light-emitting element 900 to be tested with side pads, such as optical performance testing of LEDs with side pads. The structure of the light-emitting device testing fixture 300 of the third embodiment is basically the same as that of the light-emitting device testing fixture of the first embodiment. Different from the light-emitting device test fixture 100 of the first embodiment, the structures of the base 310 and the test assembly 320 of the light-emitting device test fixture of the third embodiment are different from those of the base 110 and the test assembly 120 of the first embodiment.

[0071] The test substrate 322 is provided with probe installation holes (not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com