Concrete crushing strength automatic testing method and system

A technology of compressive strength and automatic detection, which is applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, instruments, etc., which can solve the time limit of manual operation, the influence of the accuracy of test results, and the large influence of human factors and other issues, to achieve the effect of unattended detection, flexible detection time, and little influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

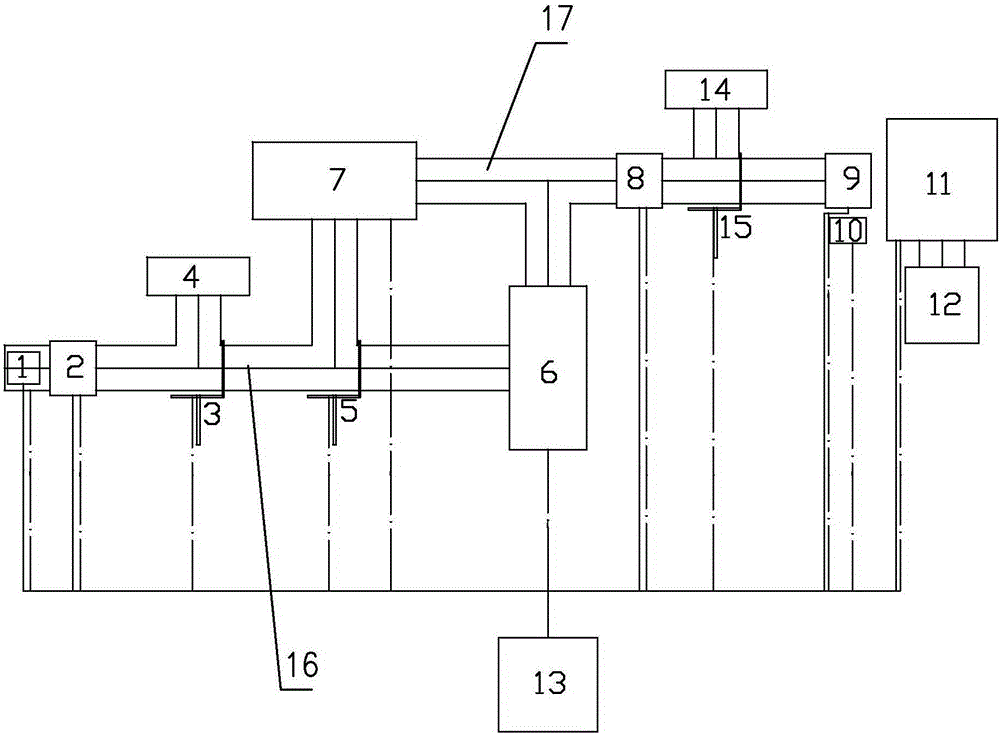

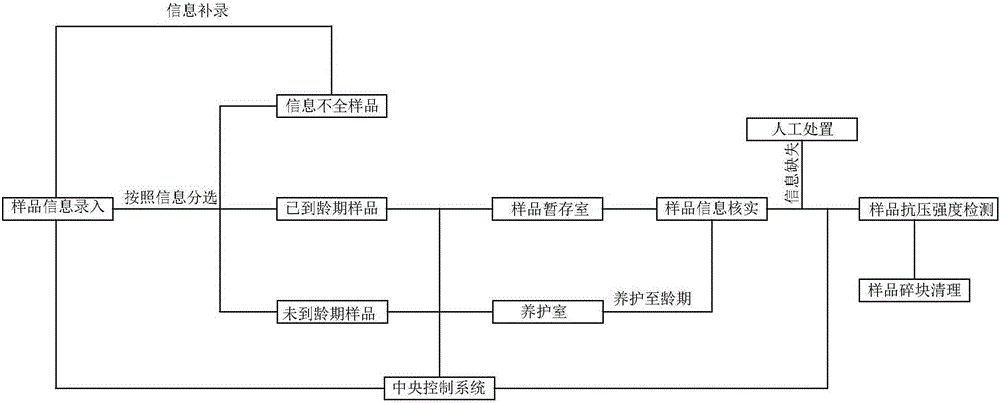

[0045] Such as figure 1 , 2 Shown, be a kind of concrete compressive strength automatic detection method of the present invention, comprise the following steps:

[0046] 1. According to the information of the concrete test block provided by the sample sending unit, including the age of the concrete test block, collection time, size, strength grade, serial number, etc., the concrete test block in this embodiment is a concrete test block of 150×150×150mm block (24 days old), enter the information of the concrete test block into the computer, and synchronize the information of the concrete test block to the central control system. The central control system generates a management code for each concrete test block, and each concrete in the control system The management code of the test block corresponds to the information of the concrete test block, the management code is set on the concrete test block, and the entire work process is controlled by the central control system;

[...

Embodiment 2

[0066] The difference between this embodiment and the embodiment is that the concrete test block is a 150×150×150mm concrete test block (the age is 28 days), and the basic information of the concrete test block is entered first, and then placed in the first pressure On the sensor 1, the first pressure sensor 1 feeds back the pressure signal to the central control system 13, and the central control system 13 starts the transport belt, and the concrete test block is transported through the infrared scanning device, and the information of the test block is fed back to the central control system 13, and the central control system 13 The control system 13 judges that the sample is an aged sample according to its age of 28 days, opens the push separation mechanism 3, closes the push separation mechanism 5, and directly transports the test block to the storage rack of the sample temporary storage room 7 through the belt and the push separation mechanism Above, the central control syst...

Embodiment 3

[0068] The difference between this embodiment and the embodiment is that the concrete test block is a concrete test block (age of 30 days) of 150 × 150 × 150mm, the management code is set on the concrete test block, and the basic information is entered (information input Incomplete), then placed on the first pressure sensor 1, the first pressure sensor 1 feeds back the pressure signal to the central control system 13, the central control system 13 starts the transport belt of the detection system, and the concrete test block is transported through the belt and passes through the infrared scanning device, Infrared scanning equipment detects that the sample information is incomplete, and immediately gives an alarm prompt. The central control system 13 activates the push separation mechanism 3 and the conveyor belt to transport the sample to the temporary storage platform, and puts it into the detection system again after the information is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com