Ceramic scintillator array and manufacturing method thereof

A technology of scintillator and ceramic powder, which is applied in the field of detectors, can solve problems such as inability to emit light, and achieve the effects of strong optical signal, improved light emission efficiency, and increased light emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

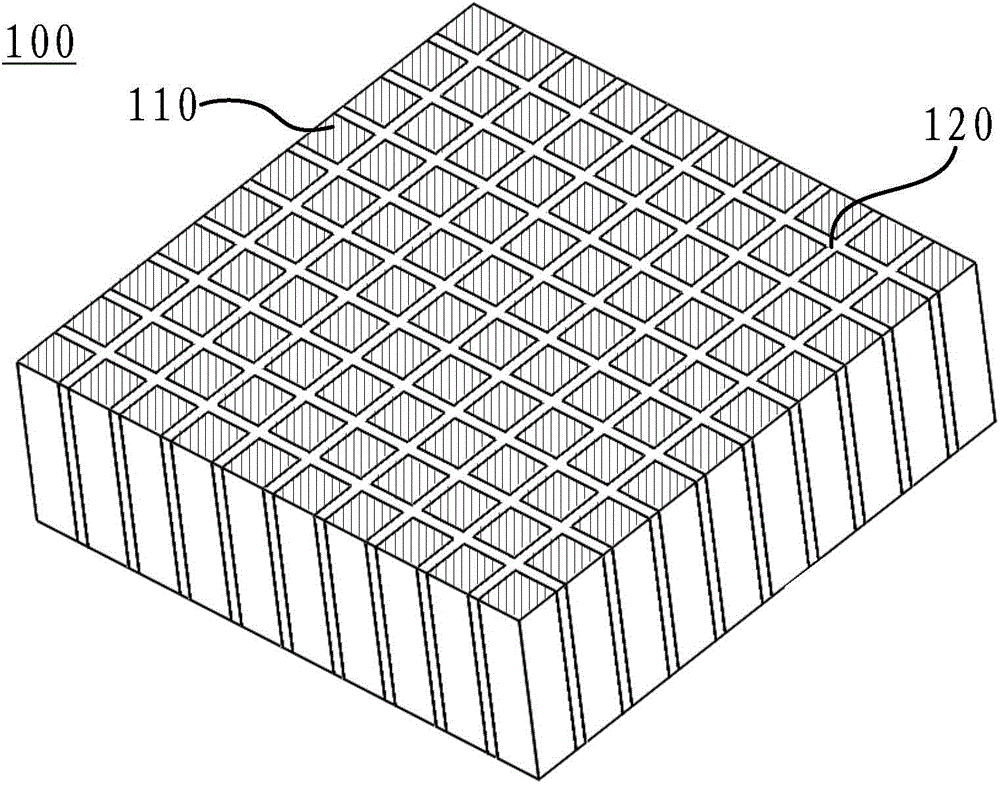

[0059] The present invention also provides a method for preparing a ceramic scintillator array, which can be used to prepare the above-mentioned ceramic scintillator array, comprising the following steps:

[0060] S100: Prepare a plurality of ceramic scintillator units.

[0061] The ceramic scintillator element can be directly prepared from the ceramic powder, including the following steps: preparing the ceramic powder according to the composition ratio of the ceramic scintillator element, grinding, mixing and drying the prepared ceramic powder; Ceramic powder through such as Figure 7 The shown unit preparation mold 200 is press-molded to obtain a plurality of ceramic scintillator unit green bodies; after sintering the plurality of ceramic scintillator unit green bodies, a plurality of ceramic scintillator unit units are obtained. This method is simple to prepare and does not require mechanical cutting, and since each ceramic scintillator unit is independent of each other, d...

Embodiment 1

[0076] (1) Preparation of ceramic scintillator elements

[0077] The matrix of the ceramic scintillator element is Y 3 Al 5 o 12 Transparent ceramics, the active ion is Ce 3+ , and Ce 3+ The doping amount is 0.00005% of the molar weight of the matrix.

[0078] The preparation process is as follows: prepare ceramic powder according to the composition ratio of the ceramic scintillator element; grind, mix and dry the ceramic powder; select a suitable element to prepare a mold, and place the dried ceramic powder in the first powder in the body containing cavity; covering the element pressing plate on the first powder containing cavity and applying a certain pressure to obtain a plurality of ceramic scintillator element green bodies. A plurality of green ceramic scintillator elements are placed in a high-temperature furnace, sintered at 1750° C. for 10 h, and taken out after cooling to obtain a plurality of columnar ceramic scintillator elements. The cross section of each cer...

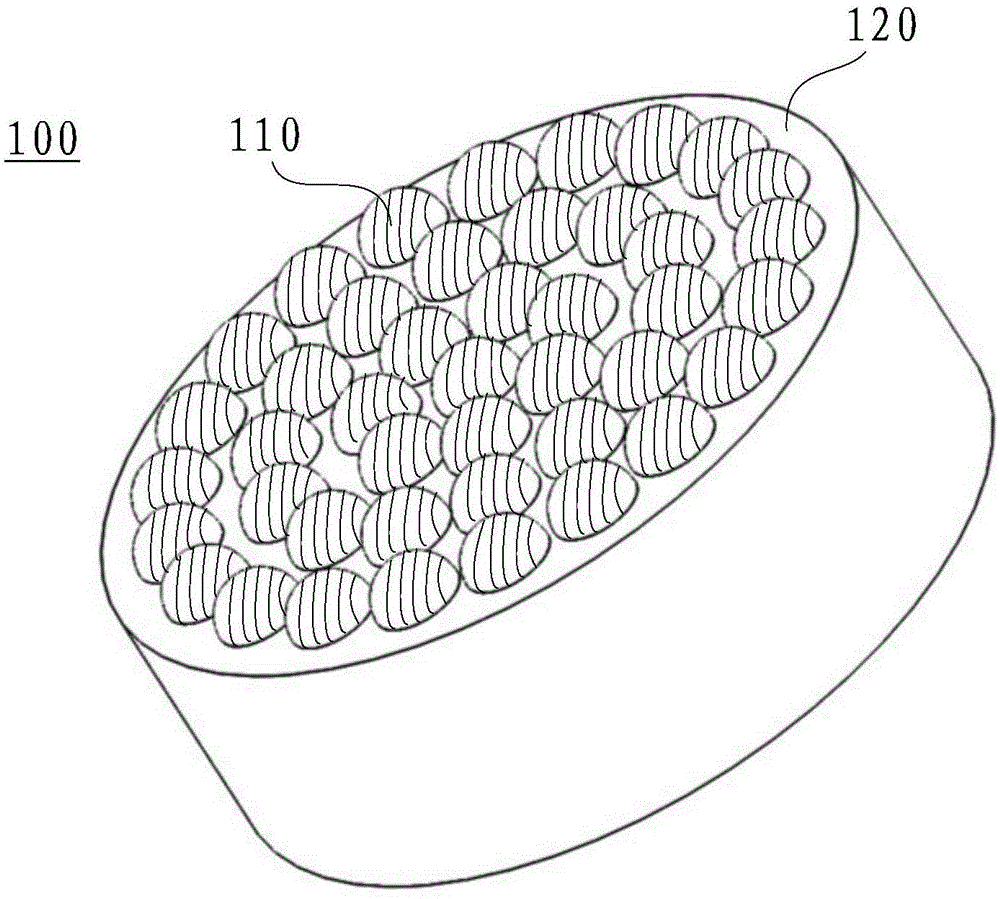

example 2

[0084] (1) Preparation of ceramic scintillator elements

[0085] The matrix of the ceramic scintillator element is selected from Lu 3 Al 5 o 12 Transparent ceramics, the active ion is Pr 3+ , and Pr 3+ The doping amount is 0.1% of the molar weight of the matrix.

[0086] The preparation process is as follows: prepare the ceramic powder according to the composition ratio of the ceramic scintillator element; grind, mix and dry the ceramic powder; select a suitable element to prepare a mold (the bottom of the first powder storage cavity is concave), The dried ceramic powder is placed in the first powder storage cavity; the base unit pressing plate is covered on the first powder storage cavity, and a certain pressure is applied to obtain a plurality of ceramic scintillator base unit green bodies. A plurality of green ceramic scintillator elements were placed in a high-temperature furnace, sintered at 1800° C. for 5 hours, and taken out after cooling to obtain a plurality of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com