3D integrated card-making system and method

A card-making and 3D technology, applied in the direction of using a printer for visual presentation, etc., can solve the problems of difficult security control, affecting the development of the industry, low level of intelligence, etc., to improve the efficiency of card-making, ensure the health of personnel, and ensure information security. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

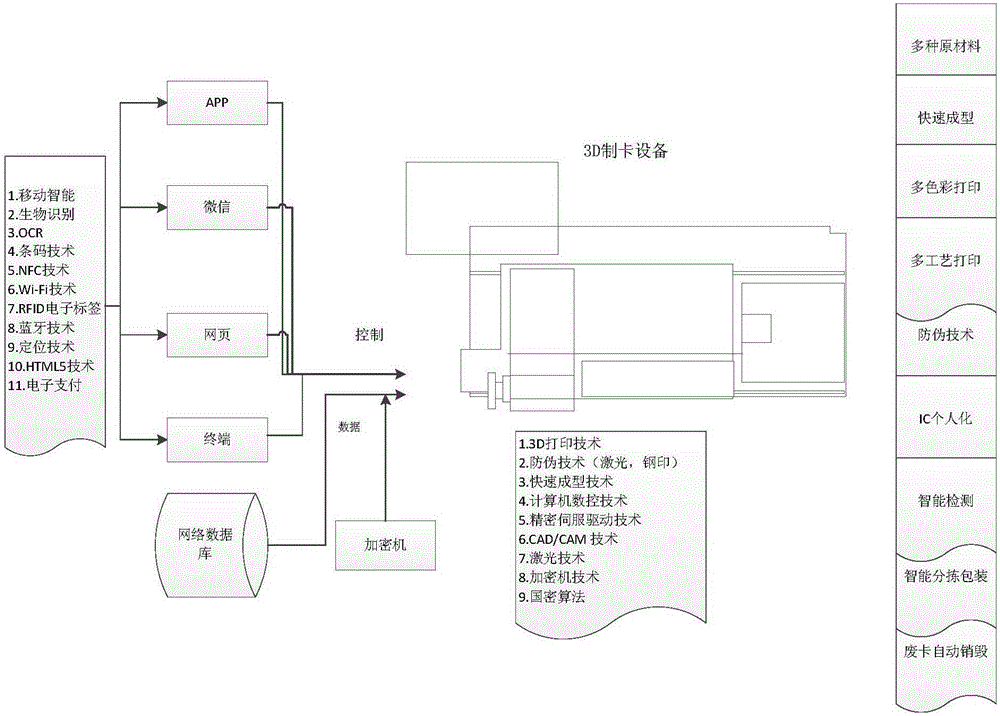

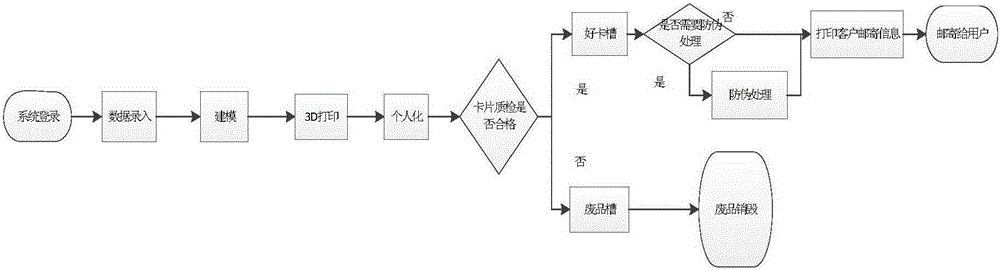

[0043] Such as figure 1 As shown, the 3D integrated card making system of the present invention includes an intelligent terminal connected to the Internet, a network database and a 3D card making device, wherein:

[0044] 3D card making equipment, including 3D printing module, digital printing module, chip data reading and writing module, OCR identification module, data decryption module and waste card processing module, used for 3D printing card making, card chip data writing, destruction quality inspection Qualified card and card quality inspection including OCR identification and card chip data reading;

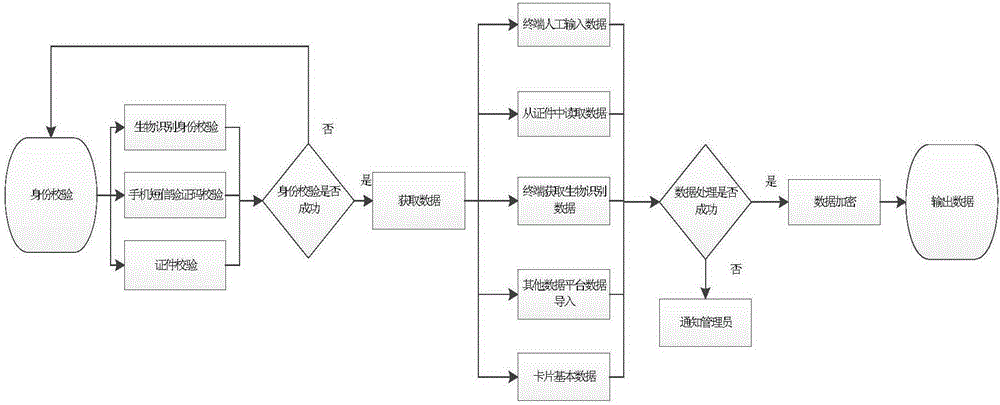

[0045] The smart terminal is used to obtain the legal identity data of the card making user and the card data of this identity;

[0046] The network database is used to store all legal identity data and card data, and encrypt and send the data to be made to the 3D card making equipment.

[0047] The smart terminal can be a mobile phone, a tablet computer, a computer, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com