Flexible perovskite solar cell and preparation technology thereof

A solar cell and preparation process technology, which is applied in the field of solar cells to achieve the effects of reducing cost, simplifying process flow and improving cell preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

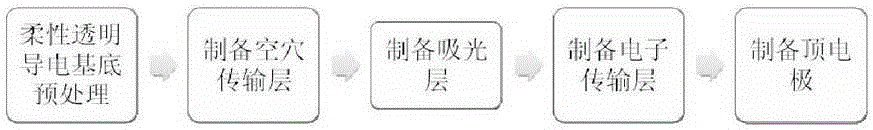

Method used

Image

Examples

Embodiment 1

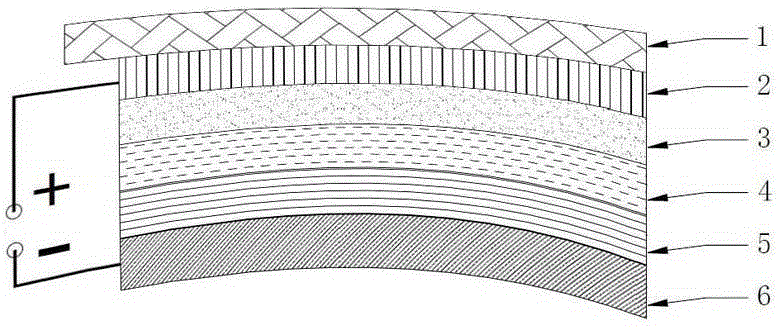

[0033] A flexible perovskite solar cell of the present invention, such as figure 1 As shown (observed from top to bottom), it includes a flexible transparent substrate 1, a transparent electrode 2, a hole transport layer 3, a light absorbing layer 4, an electron transport layer 5 and a top electrode 6 stacked in sequence. The light absorbing layer 4 is made of calcium The photovoltaic material with titanium ore structure is formed, the hole transport layer 3 is formed of a hole transport material, and the electron transport layer 5 is formed of an electron transport material.

[0034] In this embodiment, the flexible transparent substrate 1 is a flexible glass substrate with a thickness of 3 mm and a transmittance of 85%; the transparent electrode 2 is a transparent ITO electrode with a thickness of 60 nm; the hole transport layer 3 is made of PEDOT:PSS material, The thickness is 35nm; the light absorbing layer 4 adopts CH 3 NH 3 PB 3 Perovskite material, thickness is 200nm...

Embodiment 2

[0044] A flexible perovskite solar cell of the present invention, such as figure 1 As shown, it includes a flexible transparent substrate 1, a transparent electrode 2, a hole transport layer 3, a light absorbing layer 4, an electron transport layer 5 and a top electrode 6 stacked sequentially from top to bottom. The light absorbing layer 4 is made of a perovskite structure The photovoltaic material is formed, the hole transport layer 3 is formed of a hole transport material, and the electron transport layer 5 is formed of an electron transport material.

[0045] In this embodiment, the flexible transparent substrate 1 is made of PEI with a thickness of 0.3mm and a transmittance of 84%; the transparent electrode 2 is made of a transparent ITO electrode with a thickness of 100nm; the hole transport layer 3 is made of Spiro-MeOTAD material with a thickness of 40nm; absorbing layer 4 uses CH 3 NH 3 PB 3 Perovskite material, thickness is 300nm; Electron transport layer 5 adopts ...

Embodiment 3

[0055] A flexible perovskite solar cell of the present invention, such as figure 1 As shown, it includes a flexible transparent substrate 1, a transparent electrode 2, a hole transport layer 3, a light absorbing layer 4, an electron transport layer 5 and a top electrode 6 stacked sequentially from top to bottom. The light absorbing layer 4 is made of a perovskite structure The photovoltaic material is formed, the hole transport layer 3 is formed of a hole transport material, and the electron transport layer 5 is formed of an electron transport material.

[0056] In this embodiment, the flexible transparent substrate 1 is made of PEI with a thickness of 0.3mm and a transmittance of 84%; the transparent electrode 2 is made of a transparent ITO electrode with a thickness of 100nm; the hole transport layer 3 is made of Spiro-MeOTAD material with a thickness of 50nm; absorbing layer 4 uses CH 3 NH 3 PB 3 Perovskite material, thickness is 400nm; Electron transport layer 5 adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com