Reversely-rotating trowelling roller for coated battery diaphragm output of drying oven

A technology for battery separators and drying ovens, which is applied to battery pack components, separators/films/diaphragms/spacers, circuits, etc., which can solve problems such as incomplete rolling and damage, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

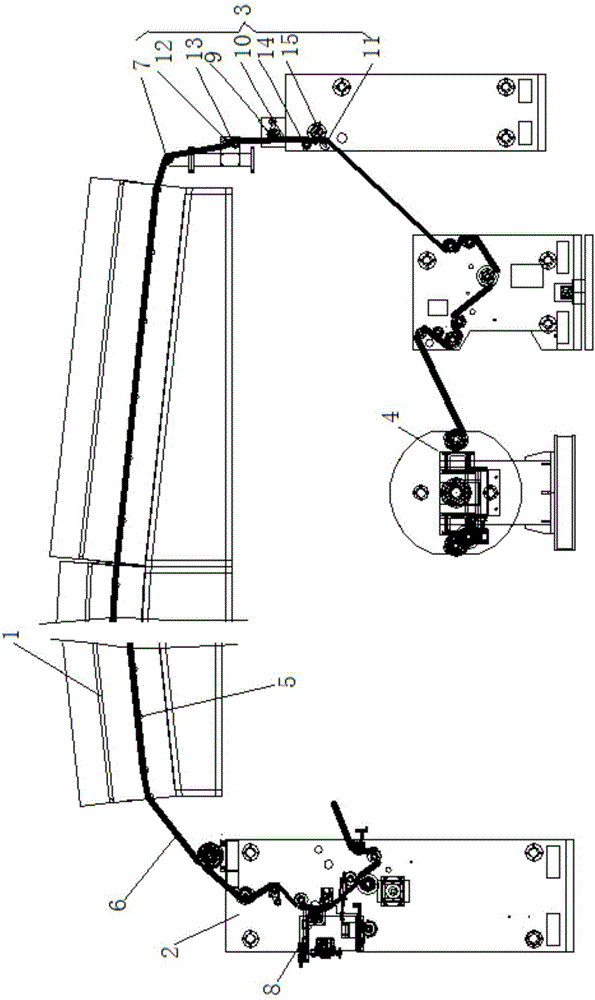

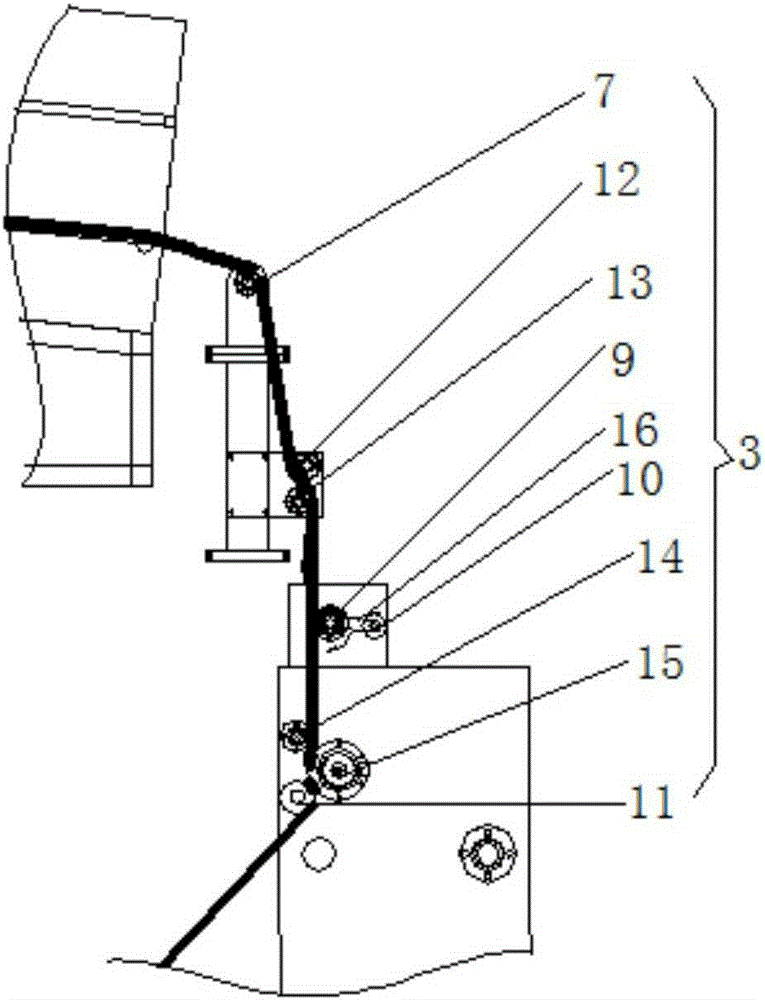

[0016] Such as figure 1 and figure 2 The shown battery separator is coated with the drying box and reversed to the smoothing roller, including the drying box 1, the coating mechanism 2 arranged on the front side of the drying box 1, and the reverse roller installed on the lower rear side of the drying box 1. To the smoothing mechanism 3, and the winding mechanism 4 arranged on the rear side of the reverse smoothing mechanism; a conveyor belt 5 is installed in the drying box 1; a film 6 is placed on the conveyor belt 5; the reverse The smoothing mechanism 3 includes a stainless steel guide roller 7, a first stainless steel guide roller group, a ceramic smoothing roller 9, a second stainless steel guide roller group and a rubber pressure roller 11 from front to back; the first stainless steel guide roller group consists of The second stainless steel guide roller 12 and the third stainless steel guide roller 13 are composed; the second stainless steel guide roller group is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com