A photovoltaic power station integrated automation system and method for adjusting active power output

A comprehensive automation and photovoltaic power station technology, applied in photovoltaic power generation, system integration technology, information technology support system, etc., can solve the problems of AGC/AVC server algorithm complexity, output period and power fluctuation, power instability, etc., to achieve It is conducive to rapid investigation, reduces the difficulty of access, and alleviates the effect of monitoring background pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

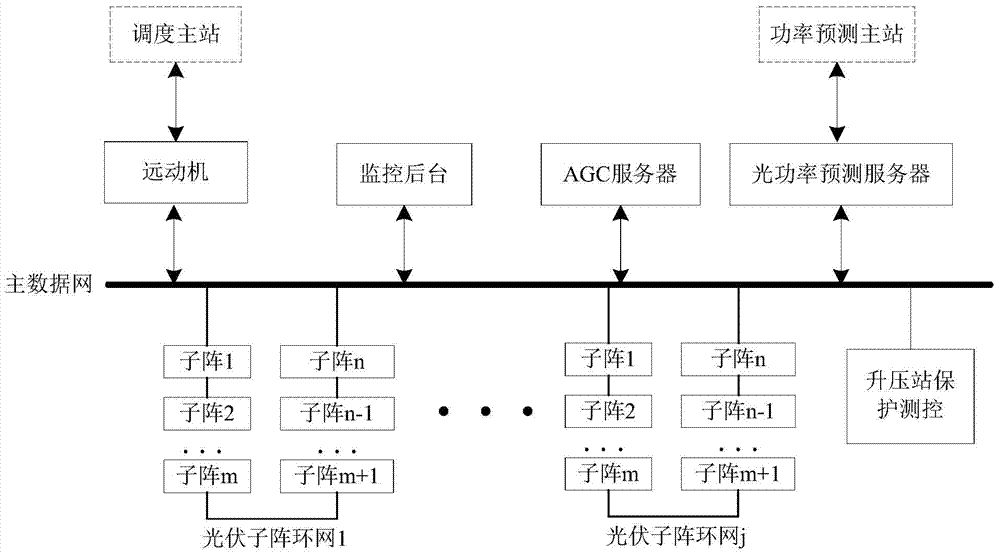

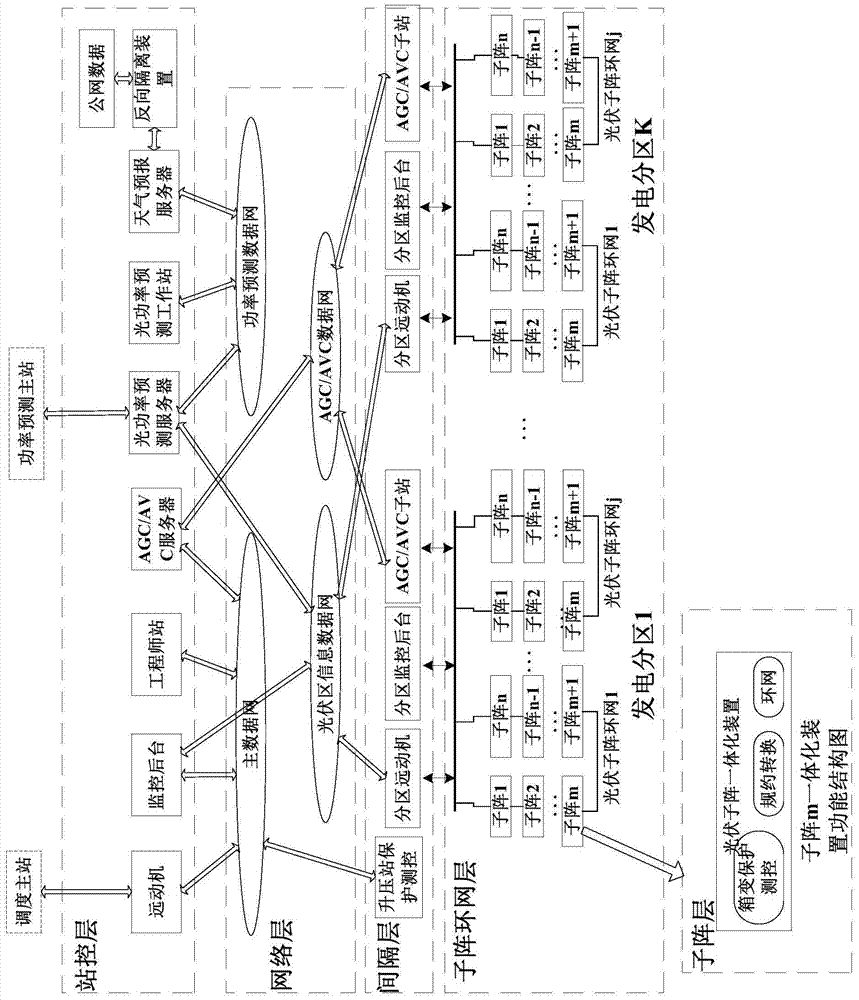

[0034] The integrated automation system of the photovoltaic power station of the present invention, as attached figure 2 As shown, bottom-up includes sub-array layer, sub-array ring network layer, bay layer, network layer, and station control layer. Each photovoltaic sub-array in the sub-array layer is equipped with a photovoltaic sub-array integrated device to realize the relay protection of the box transformer and the data collection of the equipment in the sub-array. In the sub-array ring network layer, power generation zones are divided according to actual projects. The integrated devices in the power generation zone form a sub-array ring network, and the sub-array ring networks of different power generation zones are isolated from each other. Adopt district monitoring based on power generation district. The bay level includes comprehensive automation equipment for each power generation zone and protection and monitoring devices for booster stations. In the network layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com